Flooring tile paving mechanical hand

A technology of manipulators and floor tiles, which is applied in the direction of construction and building structure, can solve the problems of slow laying speed, difficult to meet the requirements of floor tiles, and high labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

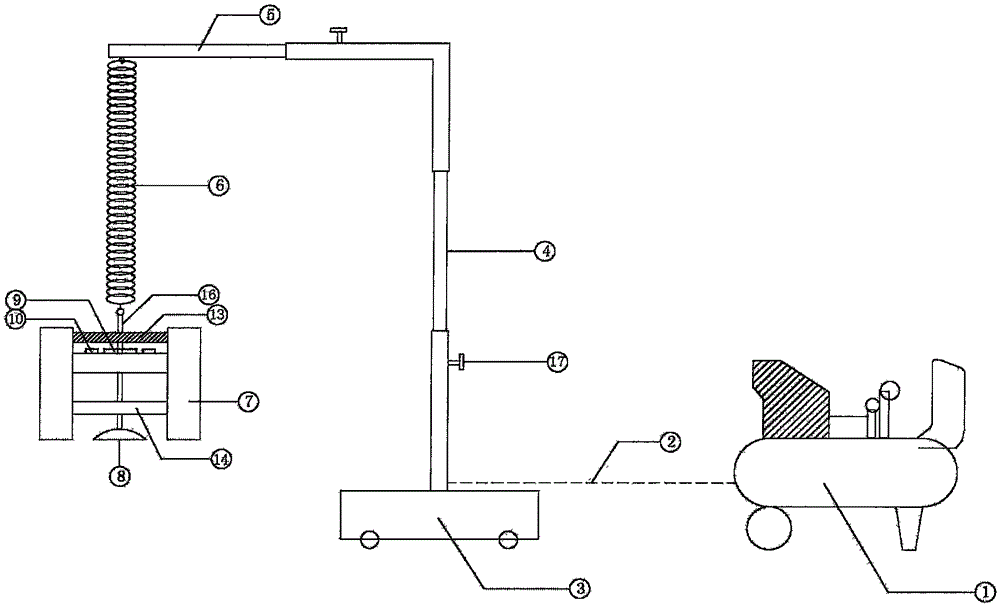

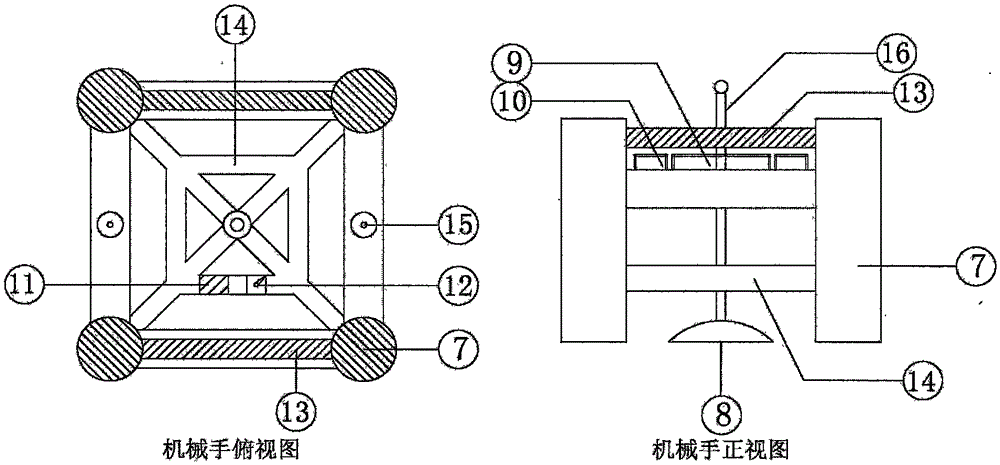

[0013] The structure of the floor tile paving manipulator in the embodiment of the present invention is as follows: figure 1 , figure 2 As shown, the air pump 1 transmits the pneumatic power to the suction cup 8 and the cylinder rubber hammer 7 through the air pipe 2. The base 3, the vertical bar 4, and the cross bar 5 are connected and fixed by the sleeve and the bolt 17 to form a support. The base 3 is provided with four wheels to move. The length of the vertical bar 4 and the cross bar 5 can be adjusted by the bolt 17, the cross bar 5 can rotate 360°, the suction cup 8 is controlled by the suction cup generator 11 and the suction cup control switch 13, the cylinder rubber hammer 7 is left by the cylinder rubber hammer double control switch 9 , right two and single control switch 10 four controls, double control switch 9 and single control switch 10 are below left and right control handle 13, both hands hold control handle 13, control cylinder rubber hammer double control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com