Bidirectional blowout-prevention ball seat for control over fluid in water well shaft

A wellbore fluid and blowout prevention ball technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of secondary blowout prevention, environmental protection hazards, formation pressure damage, etc., and achieve structural Simple and reasonable, long service life, ensuring efficient sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

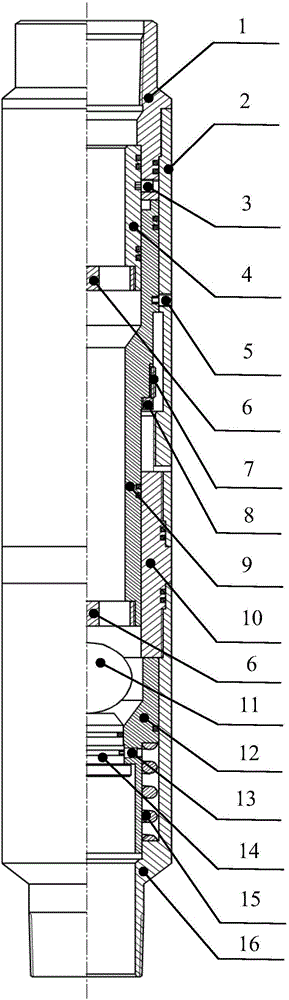

[0010] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: the present invention consists of an upper joint 1, a lock ring sleeve 2, a sliding sleeve pin 3, an impact sliding sleeve 4, a piston pin 5, a baffle plate 6, a locking ring 7, and a retaining ring 8. Piston 9, connector 10, steel ball 11, ball seat 12, live plug pin 13, live plug 14, spring 15, and lower joint 16, wherein the lock ring sleeve 2 is threaded with the upper joint 1, and the baffle plate 6 is connected with the upper joint 1. The impact sliding sleeve 4 is threaded, the impact sliding sleeve 4 is fixedly connected with the upper joint 1 through the sliding sleeve pin 3, the baffle plate 6 is connected with the piston 9 through threads, the piston 9 and the lock ring sleeve 2 are fixedly connected through the piston pin 5, and there are 7 sets of lock rings On the piston 9, the retaining ring 8 is threadedly connected with the piston 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com