Gas well underground rotational flow atomization water drainage and gas recovery device

A drainage gas recovery and gas well technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of gas wells not producing normally, gas wells stop production due to liquid accumulation, and gas well productivity is poor, so as to improve the flow state of the wellbore , clear water, increase the effect of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

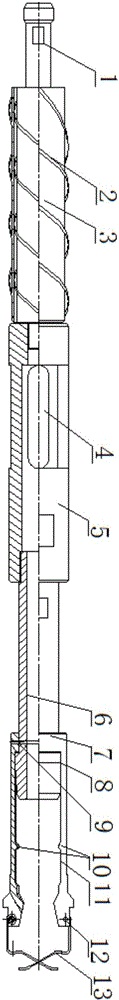

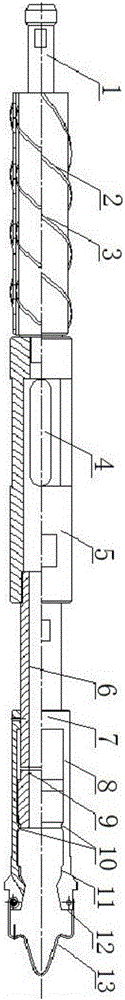

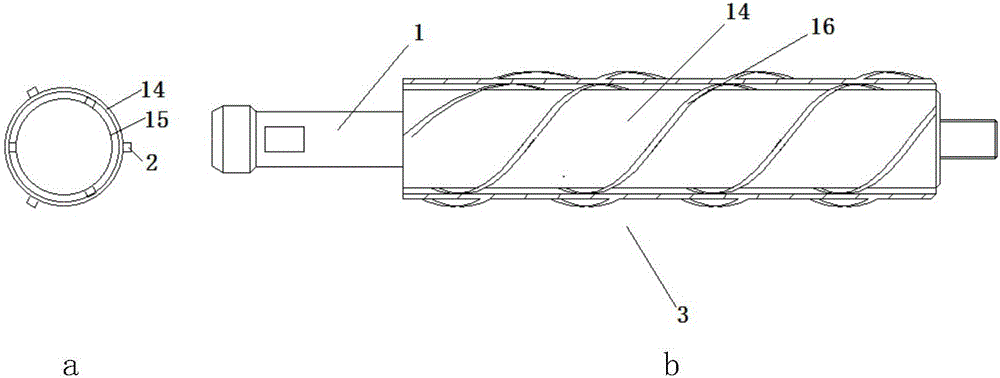

[0016] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

[0017] Such as figure 1 , figure 2 As shown, a gas well downhole cyclone atomization drainage gas production device includes a fishing head 1, the fishing head 1 is connected to the upper part of the flow bypass 3, the lower part of the flow bypass 3 is connected to the upper end of the flow guide tube 5, and the lower end of the flow guide tube 5 is connected to the upper end of the flow guide tube 5. The upper end of the cone 6 is threaded, and the outer wall of the lower end of the cone 6 is provided with a raised annular step; the elastic body 11 is sleeved on the outer wall of the cone 6 and connected by the shear pin 9. When the shear pin 9 is cut off, the elastic body 11 can Slide on the cone 6 outer walls; the elastic body 11 outer wall connection adopts an end of the spring pin 12 that steel wire is bent into;

[0018] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com