Environmental control system of wind generating set and control method of environmental control system

A technology for wind turbines and control systems, which is applied in the control of wind turbines, wind turbines, and wind power generation, etc., can solve the problems of prolonging the construction period of wind farms, increasing the cost of cables, and inability to form a complete wind turbine, achieving increased Effectiveness of dehumidification efficiency, improved integrity, simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings, examples of which are shown, in which like reference numerals refer to like components throughout.

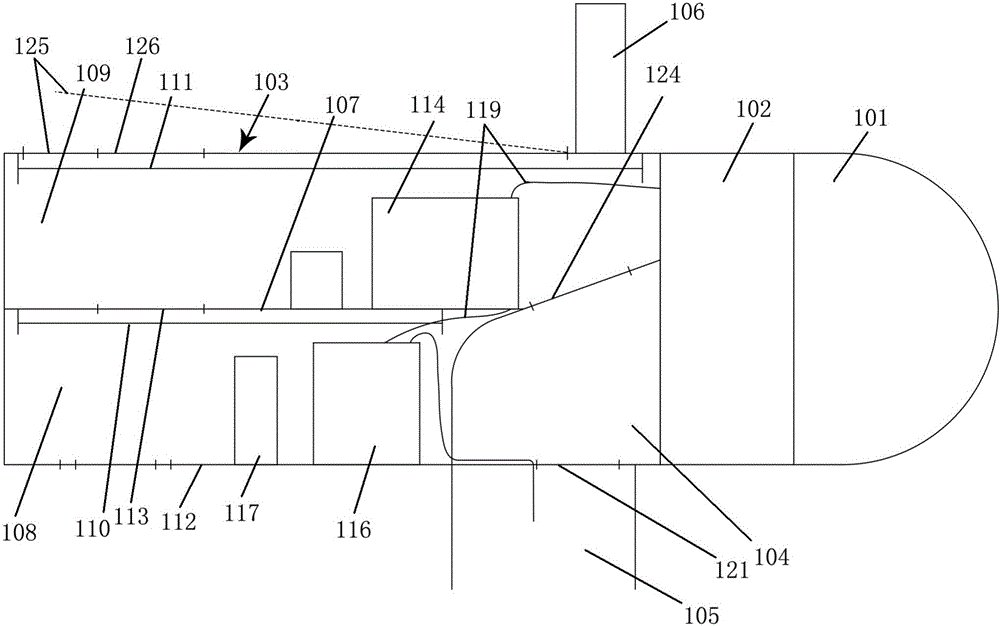

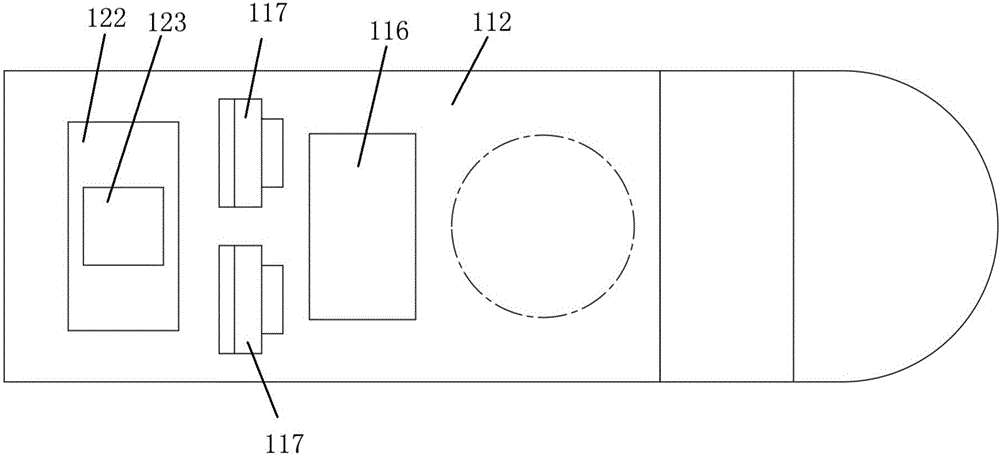

[0033] refer to figure 2 , the wind power generating set may include: an impeller 101, 101 of which may be provided with blades (not shown); a generator 102, connected to the impeller 101; a nacelle 103, a box change 116 and a converter cabinet 114 may be arranged in the nacelle 103; The tower 105 is used to support the impeller 103, the generator 102 and the nacelle 103 (the hub of the impeller, the generator and the nacelle are collectively referred to as the nose). In addition, the exterior of the nacelle 103 may also be provided with an external heat exchanger 106 for heat dissipation of the wind power generator set. Preferably, the external heat exchanger 106 may be located on the top of the nacelle 103 close to the generator 102 . Here, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com