City gas polyethylene pipe safe operation maintenance realization method and system

A technology of safe operation and realization method, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of poor inspection, unfavorable safe operation and maintenance of pipelines, pipeline leakage damage and leakage, etc., to avoid Leakage damage and leakage, to achieve the effect of safe operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a method and system for realizing the safe operation and maintenance of polyethylene pipelines for urban gas. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

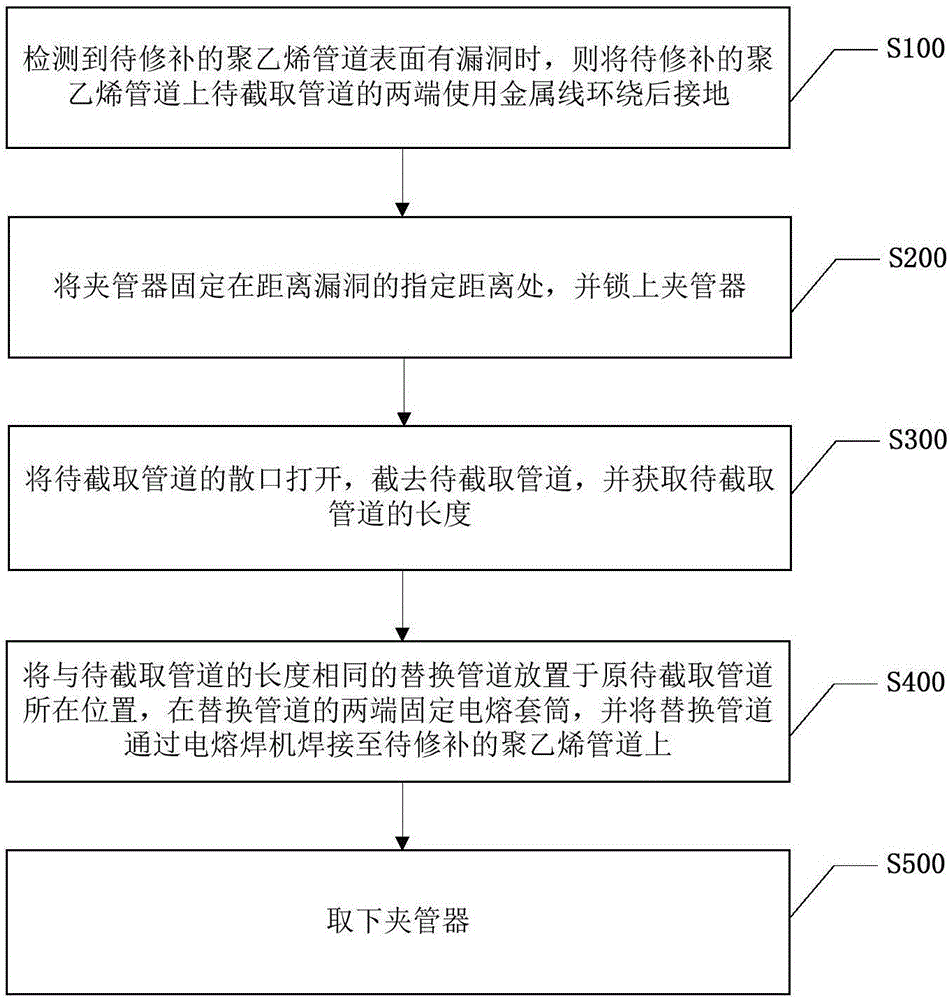

[0023] Such as figure 1 As shown, it is a flow chart of a preferred embodiment of the method for realizing the safe operation and maintenance of the urban gas polyethylene pipeline of the present invention, and the method includes the following steps:

[0024] Step S100, when it is detected that there is a leak on the surface of the polyethylene pipe to be repaired, the two ends of the pipe to be intercepted on the polyethylene pipe to be repaired are surrounded by metal wires and then grounded;

[0025] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com