Multifunctional wood and coal furnace capable of preventing fire bar melting

A multi-functional heating furnace technology, applied in the field of heating furnaces, can solve the problems of low heat absorption efficiency, low thermal efficiency, backward technology, etc., and achieve the effects of increasing residence time, improving thermal efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

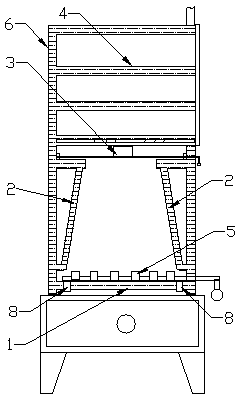

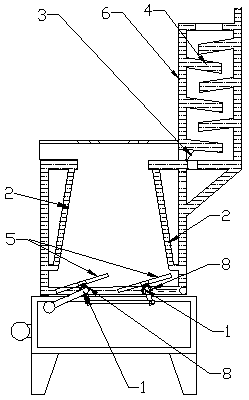

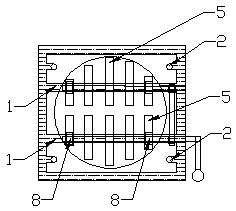

[0012] exist figure 1 , figure 2 , image 3 Among them, a grate 5 is arranged at the lower part of the hearth, and heat-absorbing fins 4 are arranged inside the heat-absorbing box 6. It is characterized in that: two stove leg grate support water pipes 1 are horizontally arranged at the lower part of the grate 5, and each grate supports Two ends of the water pipe 1 are respectively provided with a U-shaped groove 8, and a group of furnace bars 5 are respectively arranged on the two U-shaped grooves 8. In this embodiment, four heat-absorbing risers 2 are vertically arranged around the furnace, A rotary valve 3 is arranged at the smoke outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com