A frame detection platform

A detection platform, a pair of technology, applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve the problems of unfavorable A-frame movement, unfavorable transportation and debugging, non-disassembly, etc., to achieve easy detection and easy processing. , the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

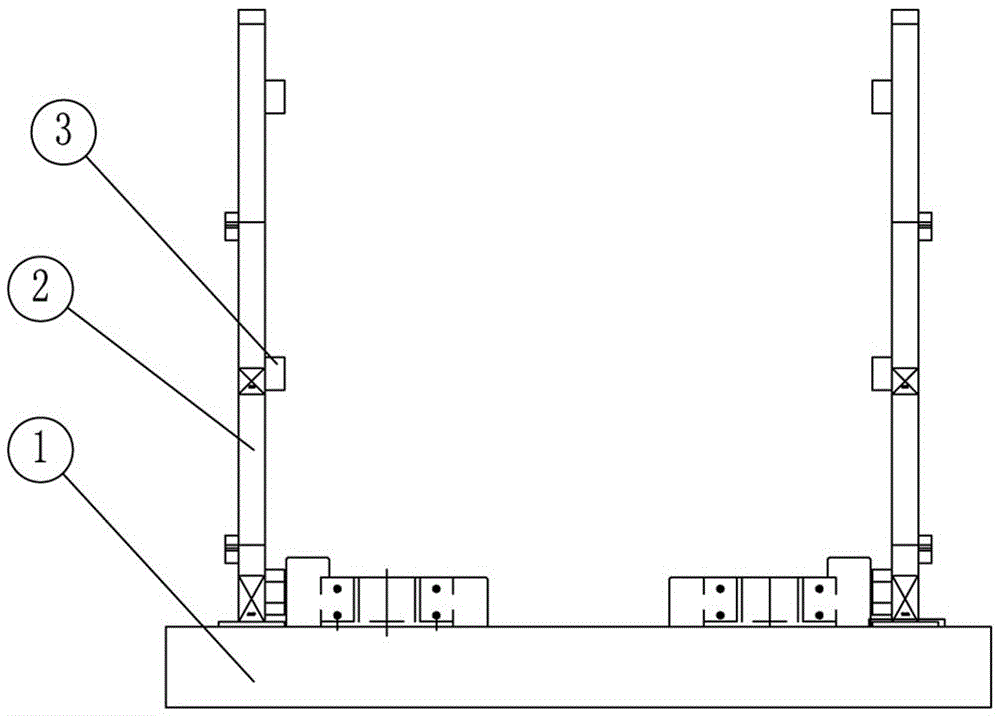

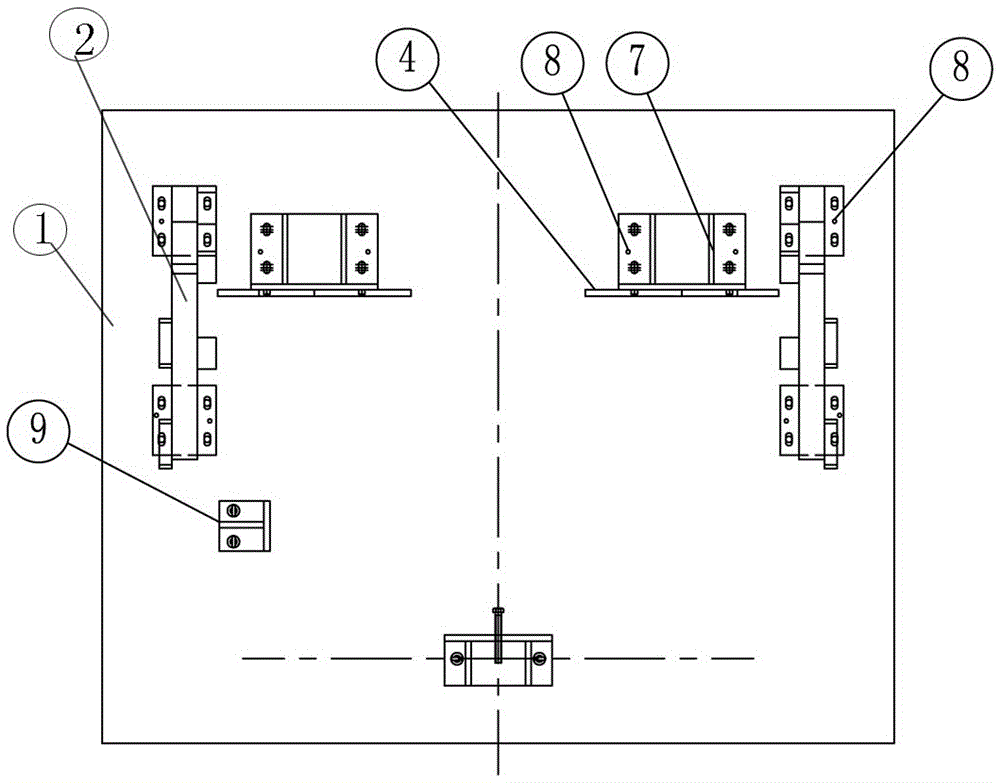

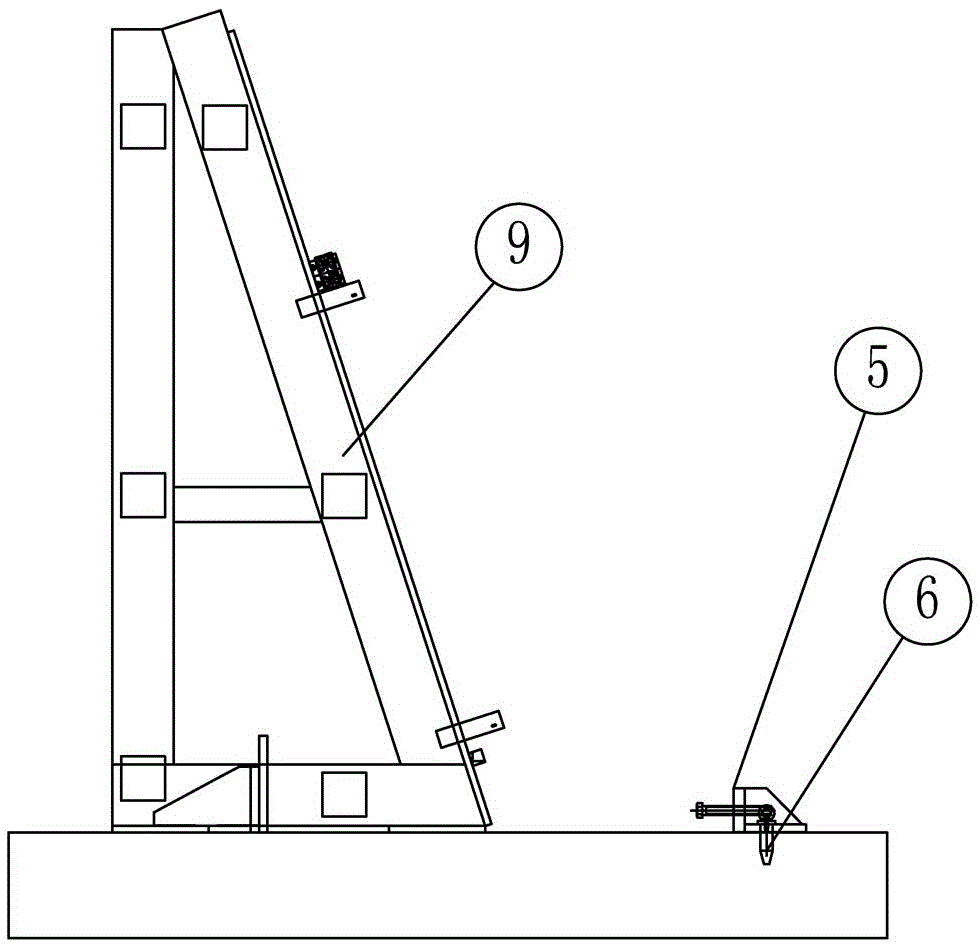

[0017] as attached figure 1 As shown, the embodiment of the present invention is an A-frame detection platform, which includes a cast iron plate 1, a tripod 2, a reference block 3, a rear baffle 4, a front tightening device 5, a latch 6, a rear stop 7, a positioning pin 8, Side positioning 10; A-frame 9 completes detection on this platform.

[0018] Among them, the cast iron plate 1 provides the datum plane of the platform, and the tripod 2 is a pair, which is symmetrically assembled on both ends of the cast iron plate 1. The two hypotenuses of the pair of tripods 2 form a 72-degree plane, which is convenient for detecting the angle of the A-frame backplane ( The A-frame back plate is theoretically a 72-degree plane), the tripod 2 and the cast iron plate 1 are connected by bolts, and the pins are positioned. The reference block 3 that provides the left and right position reference of the A-frame is assembled and fixed at the inner symmetrical position of each tripod, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com