Easy quantitative sampling device for inhomogeneous powder

A non-uniform and quantitative sampling technology, which is applied in the field of mines and drilling, can solve problems such as affecting sampling efficiency, inaccurate sampling quantification, and poor sample representativeness, and achieve the effects of improving work efficiency, reducing labor intensity, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

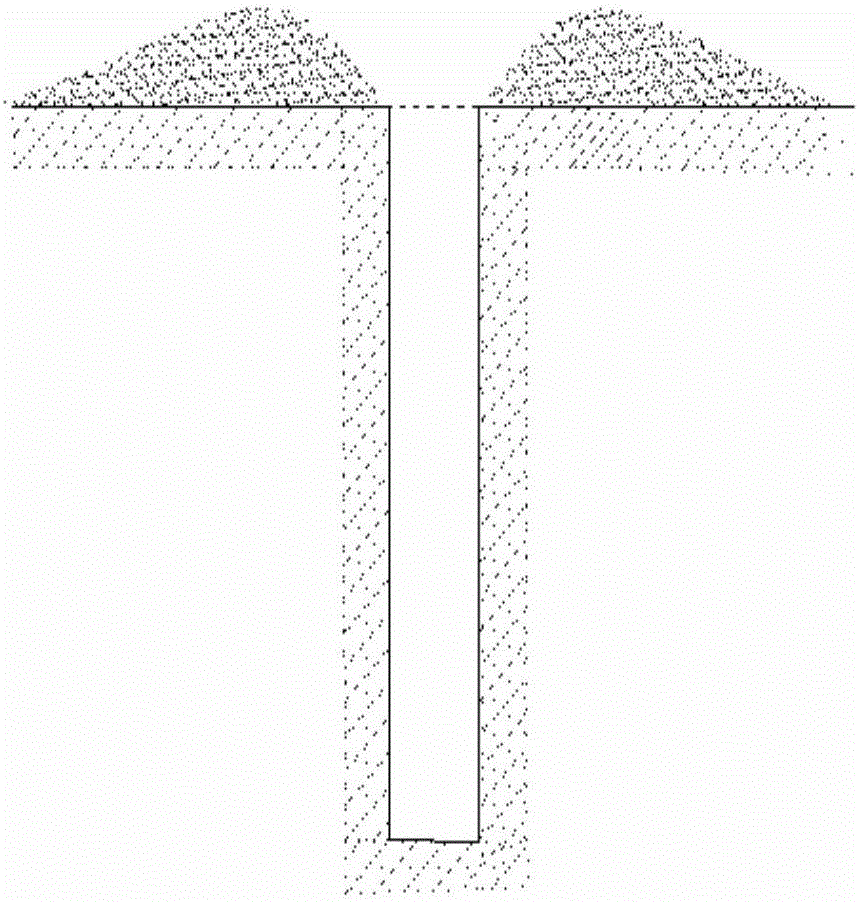

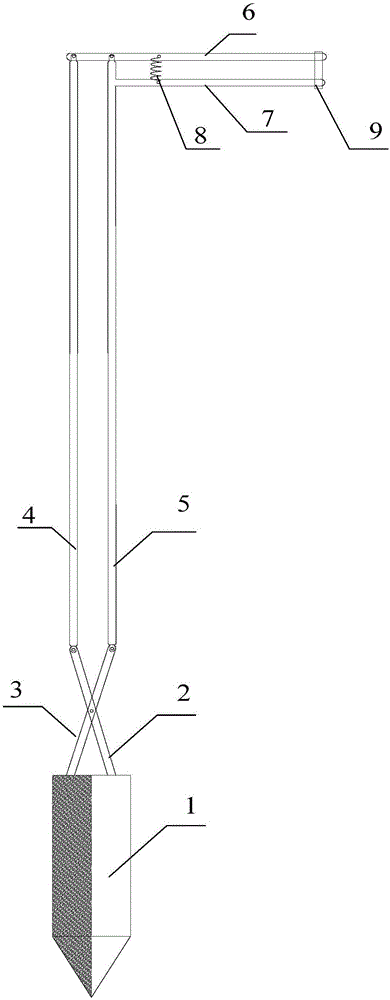

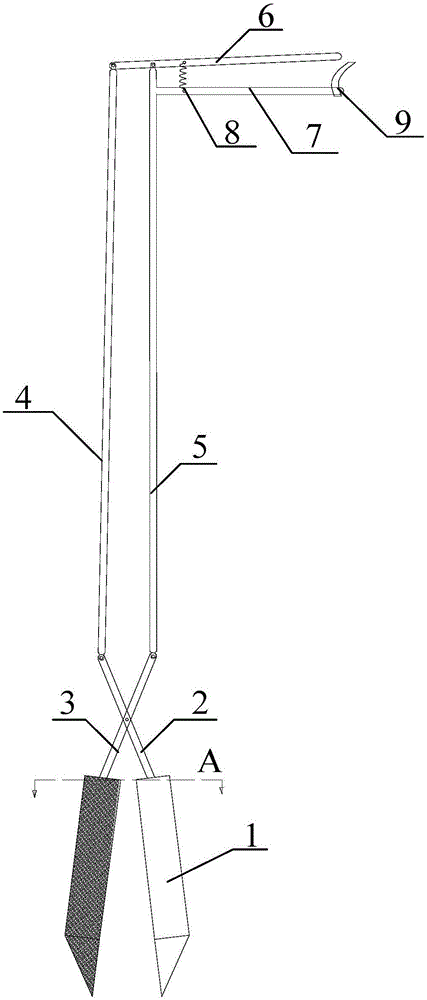

[0028] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] In the embodiment of the present invention, such as figure 2 with image 3 As shown, the convenient quantitative sampling device for non-uniform powder includes: a sampler 1 for clamping non-uniform powder, a first connecting rod 2, a second connecting rod 3, a first extension rod 4, and a second extension rod 5. Open and close the handle to rotate the support rod 6, the handle 7 and the spring 8; wherein, such as Figure 4 As shown, the sampler 1 includes a cylindrical part 1-1 and a conical part 1-2, and the lower end of the cylindrical part 1-1 is fixedly connected with the upper end of the conical part 1-2; When , the sampler expands symmetrically along the central axis of the cylinder into two parts of the cavity, such as Figure 5 Shown, that is, the first sampling cavity 1-3 and the second sampling cavity 1-4;

[0030] In the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com