A substation inspection robot cluster management and control system

An inspection robot and management and control system technology, applied in the field of substation inspection, can solve the problems of limited monitoring mode, no centralized management and control background, waste, etc., to achieve network environment security, improve resource utilization, and reduce network delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described in conjunction with the following examples.

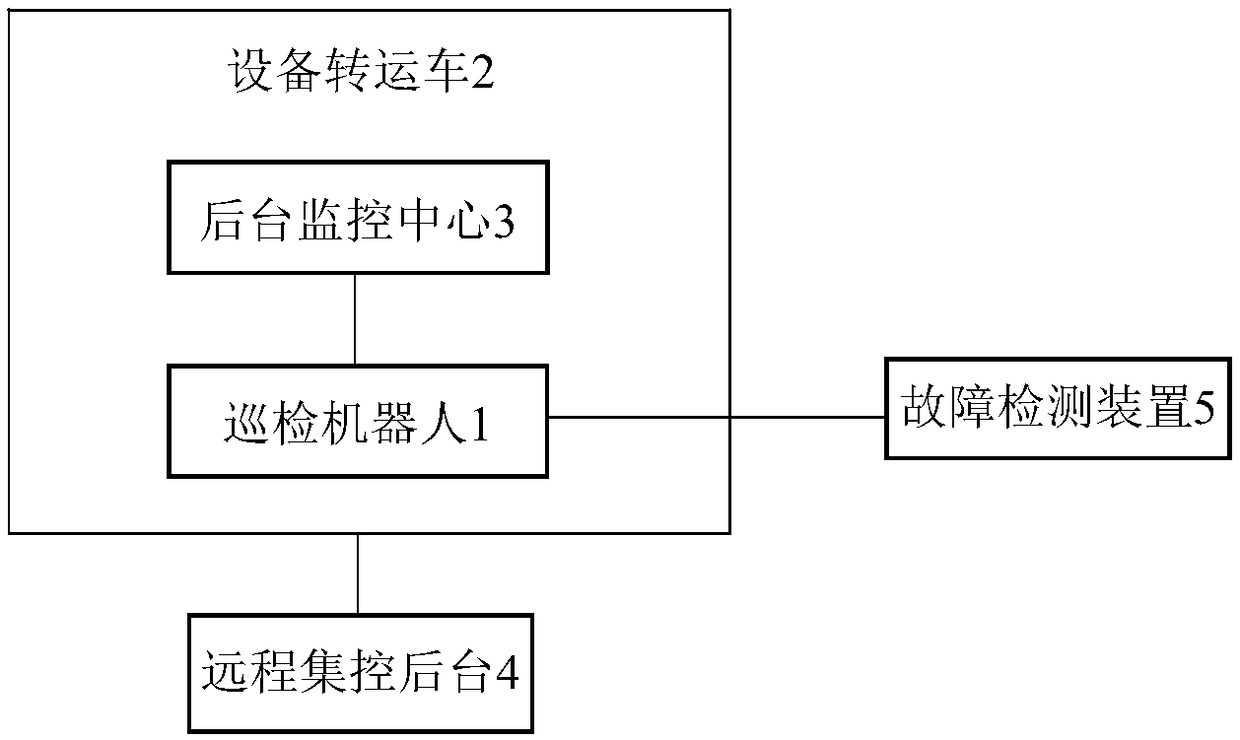

[0013] see figure 1 , this embodiment provides a substation inspection robot cluster management and control system, including an inspection robot 1, an equipment transfer vehicle 2, a background monitoring center 3 and a remote centralized control background 4, and the background monitoring center 3 is set on the equipment transfer vehicle 2 In general, the inspection robot 1 can be transferred between substations through the equipment transfer vehicle 2, and information interaction between the inspection robot 1 and the background monitoring center 3 in charge of transfer is carried out through a wireless local area network, and the background monitoring center 3 and all Information exchange between the above-mentioned remote centralized control backgrounds 4 is carried out through a private network.

[0014] Preferably, the inspection robot 1 is provided with a unique two-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com