Information-based pelletizing, drying and entire granule mixed production system

A production system and drying technology, applied in general control system, control/regulation system, program control, etc., can solve problems such as affecting production effect and efficiency, obstacles to intelligent management of factories, and poor sealing, so as to improve production efficiency and improve production efficiency. The effect of coordinating process links and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4, system preparation specific ( or approach ): system 、 and Embodiment :,,,。 approach ,、 system , and and ,,、 and ,, approach ,。 and and 、、。 Embodiment 5

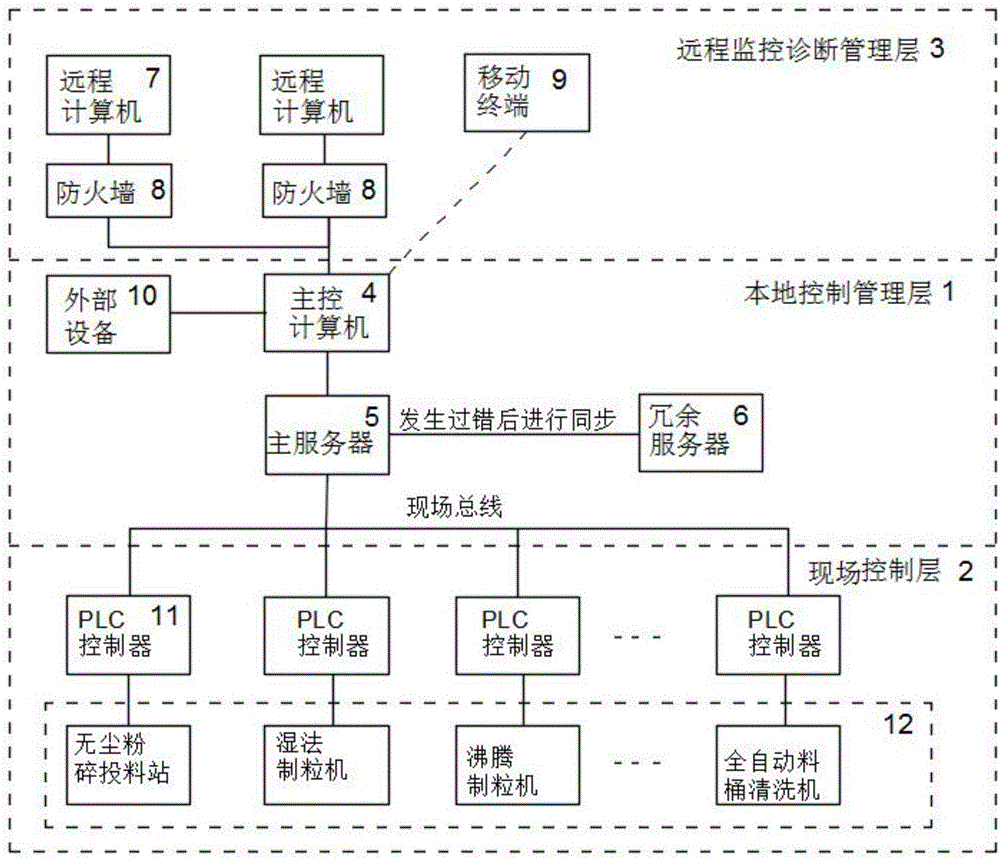

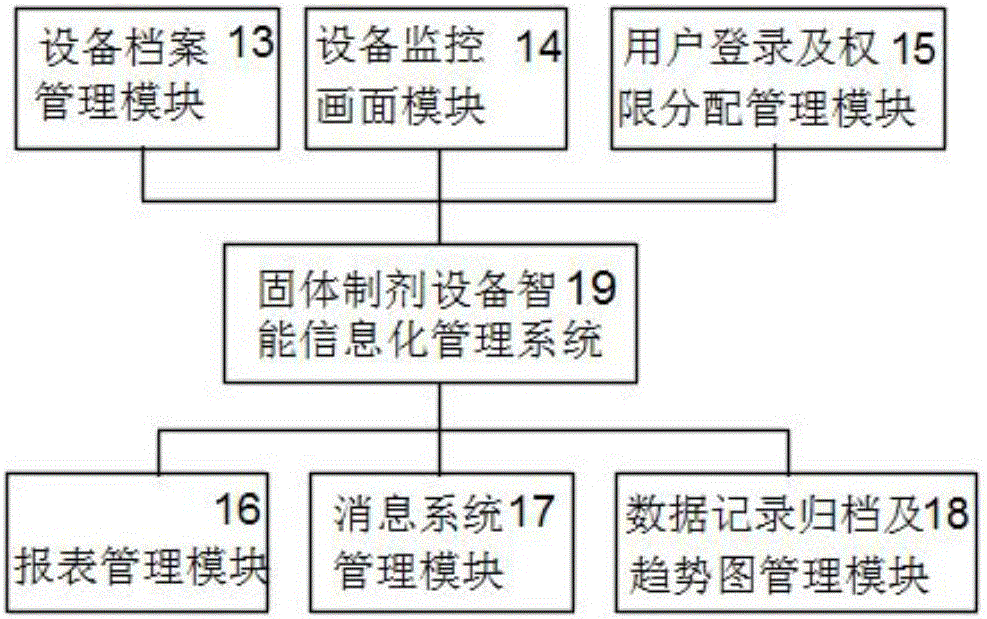

[0029] Example 4, the specific control process (or process method) of the production management of the solid preparations of the information-based granulation, drying and granulation mixed production system includes: through the corresponding monitoring and management function modules of the intelligent information management system, through the on-site intelligent The control device and the corresponding execution device implement the flow of materials in the whole production process in a vertical layered arrangement: the materials are sent to the highest layer, and then flow to the lower layer in sequence with the process steps, and the gravity of the materials is used to complete the transfer of materials. This production control process method can well solve the problems such as the need for multi-storey factory buildings due to the vertical layered arrangement, each floor needs to be equipped with a human cleaning and material cleaning system, and the inconvenient connectio...

Embodiment 6

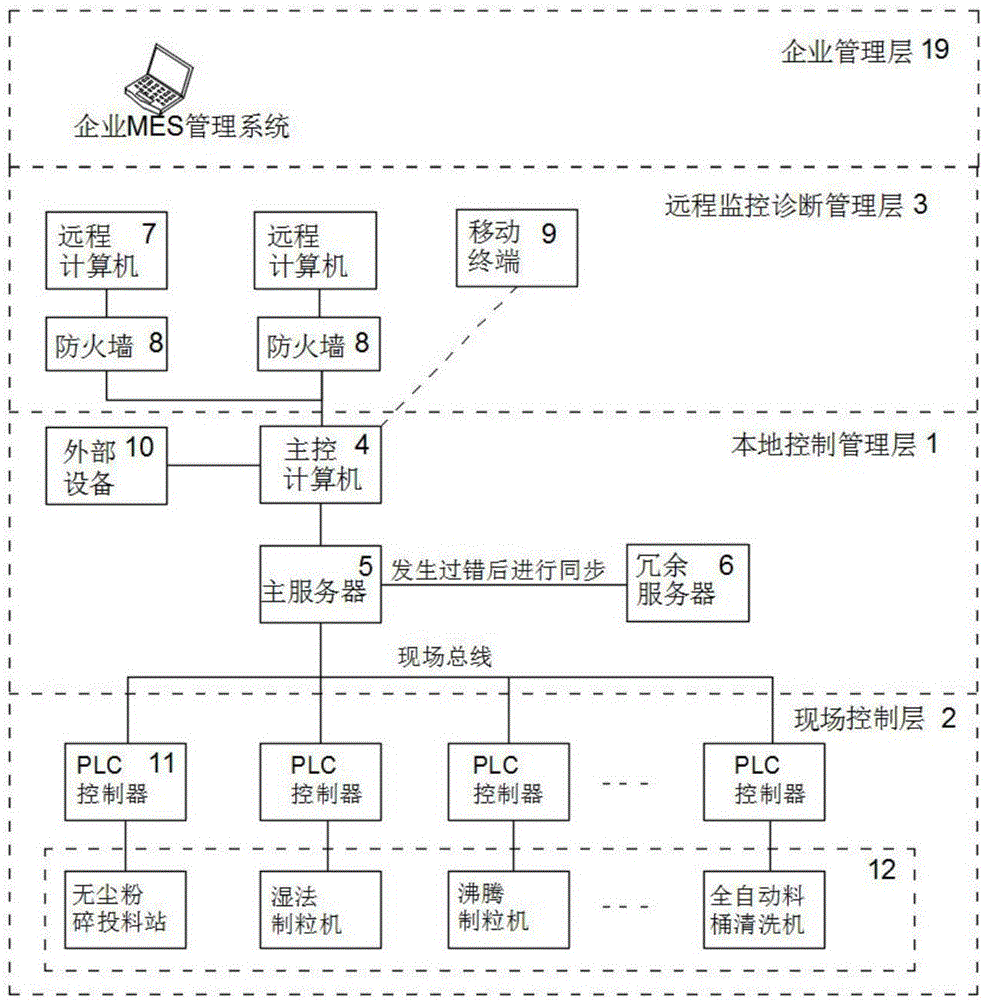

[0030] Example 6 as image 3 shown. The present invention also constructs a manufacturing enterprise production process execution system (enterprise MES management system) through remote monitoring of the management layer, thereby forming the enterprise management layer 19 . The MES management system of the enterprise connects the relevant production plan with the workshop operation site through the relevant interface through the execution device including PLC controller, data collector, bar code, corresponding measurement and sensor and / or manipulator, and through two-way direct communication Provide mission-critical information about product behavior within the enterprise and throughout the product supply chain, including establishing partnerships with manufacturers that provide production site control facilities, and provide enterprises with manufacturing data management, planning and scheduling management, production scheduling management, and inventory management. , qual...

Embodiment 9

[0034] Example 9 as Figure 4 shown. The on-site production equipment (system) of the information-based granulation, drying and granulation mixed production system of the present invention is an integrated mixed production line, which divides the entire production line or system into several subsystems, and each subsystem corresponds to or connects with each other in sequence according to the process sequence. The corresponding connections are connected by soft connection, steel wire hose connection and / or clamp closed hard connection, and each subsystem is implemented by the local control management layer or its main control computer through the field control layer or its intelligent controller Full automatic operation management control.

[0035] The working and operating parts of all subsystems are all exposed, and the related equipment or devices of each subsystem are installed horizontally or / and vertically on the outer surface of the mobile platform, and the power parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com