System and method for cleaning settled dirt in switch cabinet

A cleaning method and switchgear technology, applied in switchgear, electrical components and other directions, can solve the risk of electric shock, reduce power supply reliability, electric shock and other problems, and achieve the effect of improving power supply reliability, reducing power outage time, and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

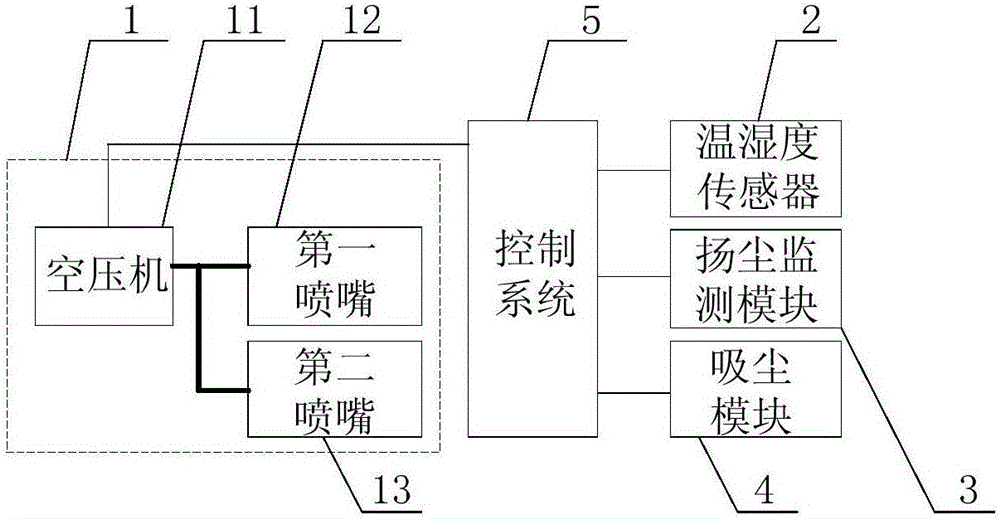

[0043] see figure 1 , the present invention discloses a settlement pollution cleaning system in a switch cabinet, comprising a dust raising module 1, a dust raising monitoring module 3, a dust suction module 4 and a control system 5;

[0044] The air outlet of the dust raising module 1, the dust raising monitoring module 3, and the air inlet of the dust collection module 4 are all arranged in the switch cabinet;

[0045] The dust raising module 1 is used to arouse the sedimentation pollution in the switch cabinet;

[0046] The dust monitoring module 3 is used to detect the dust concentration in the switch cabinet;

[0047] The dust raising module 1 , the dust raising module 3 and the dust collection module 4 are all connected to a control system 5 .

[0048] The dust raising module 1 includes an air compressor 11 and a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com