A device for automatic camera measurement of screw cone gear meshing seal

A spiral bevel gear, automatic photographing technology, applied in the direction of television, closed-circuit television system, electrical components, etc., can solve the problems such as difficult to keep records, difficult to trace and find gear contact marks, complicated recording and operation process, etc., to achieve good recording accuracy. , high degree of automation, the effect of ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

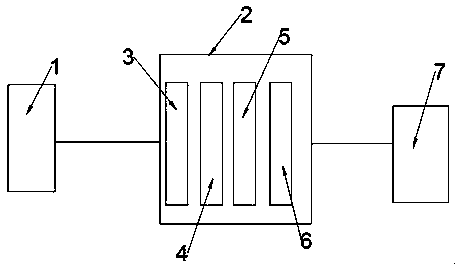

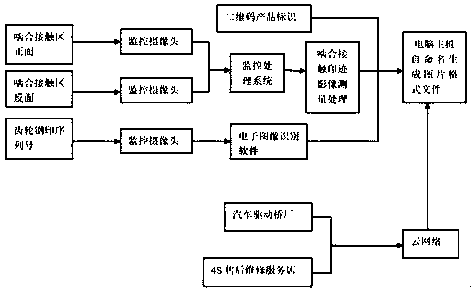

[0020] see Figure 1-2 , a device for automatically photographing and measuring the meshing contact marks of spiral bevel gears, comprising a monitoring system 1, a computer host 2, software for automatic naming of screenshots 3, image measurement software 4, electronic image recognition software 5, automatic two-dimensional code identification system 6 and cloud Network 7, monitoring system 1 is connected with host computer 2, screenshot automatic naming software 3, image measurement software 4, electronic image recognition software 5, automatic two-dimensional code identification system 6 are all installed in host computer 2, host computer 2 and cloud network 7 connected.

[0021] The monitoring system 1 includes 3 groups of monitoring cameras, and the monitoring cameras are electrically connected to the display screen of the host computer 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com