fuel pump controls

A technology for control devices and fuel pumps, applied to liquid fuel feeders, charging systems, combustion engines, etc., to achieve the effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment in which the present invention is embodied as a control device for a fuel pump for an engine mounted on a two-wheeled vehicle will be described below.

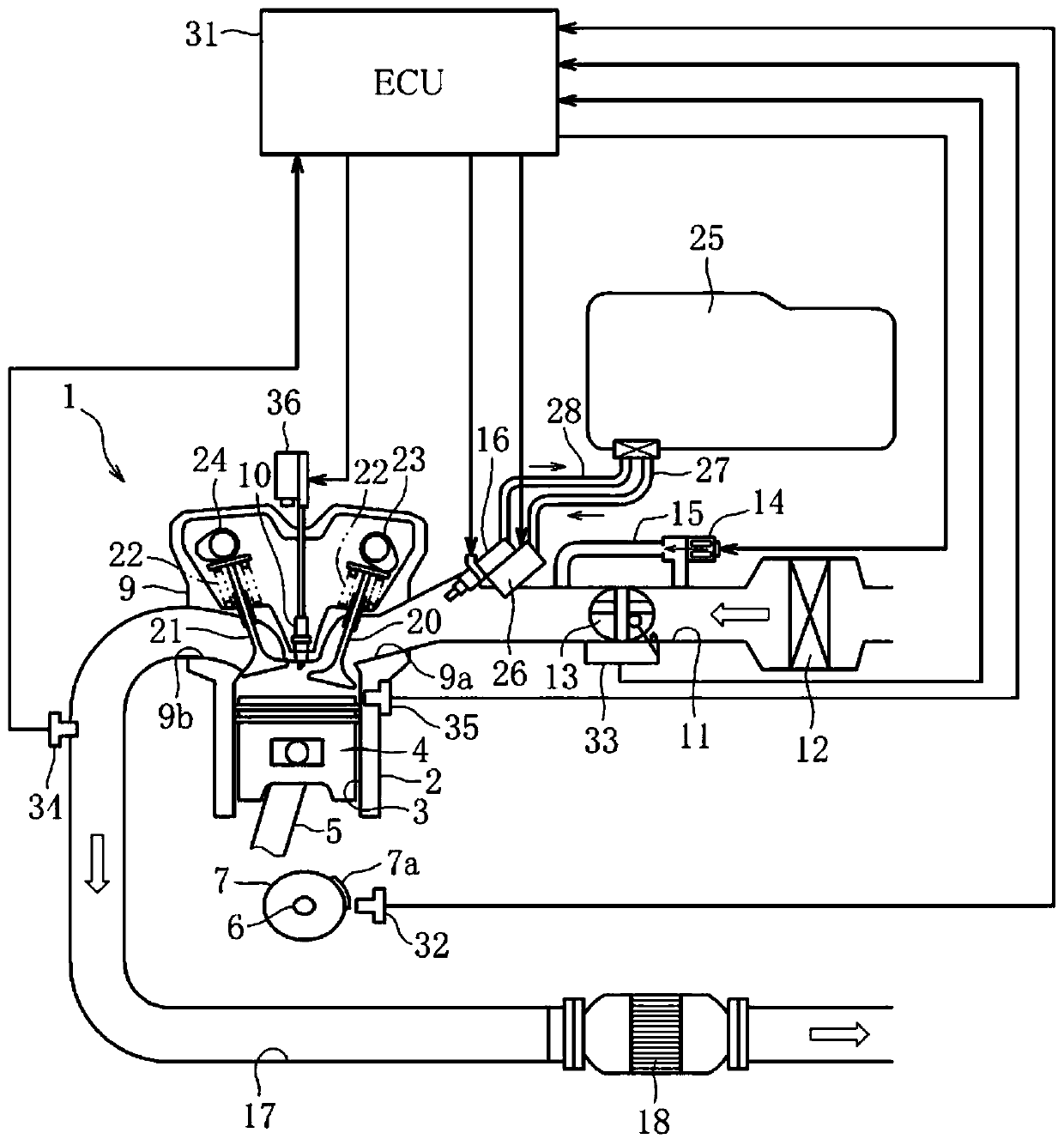

[0036] figure 1 It is a system configuration diagram showing a fuel pump control device according to the present embodiment.

[0037] The engine 1 of the present embodiment is configured as a four-stroke single-cylinder gasoline engine with a displacement of 50 cc, and is mounted on a two-wheeled vehicle as a driving power source. However, the specifications of the engine 1 are not limited thereto, and may be changed arbitrarily. However, the specifications of the engine 1 are not limited thereto, and may be changed arbitrarily.

[0038]A piston 4 is slidably disposed in a cylinder 3 formed on a cylinder block 2 of the engine 1 . The piston 4 is connected to a crankshaft 6 via a connecting rod 5 . The crankshaft 6 rotates in conjunction with the reciprocating motion of the piston 4 . A flywheel 7 is att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com