Quantitative pump

A quantitative pump and pump body technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of unable to achieve quantitative filling, unable to achieve quantitative measurement, affecting the effect of medium use, etc., to achieve light weight, compact structure, disassembly simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

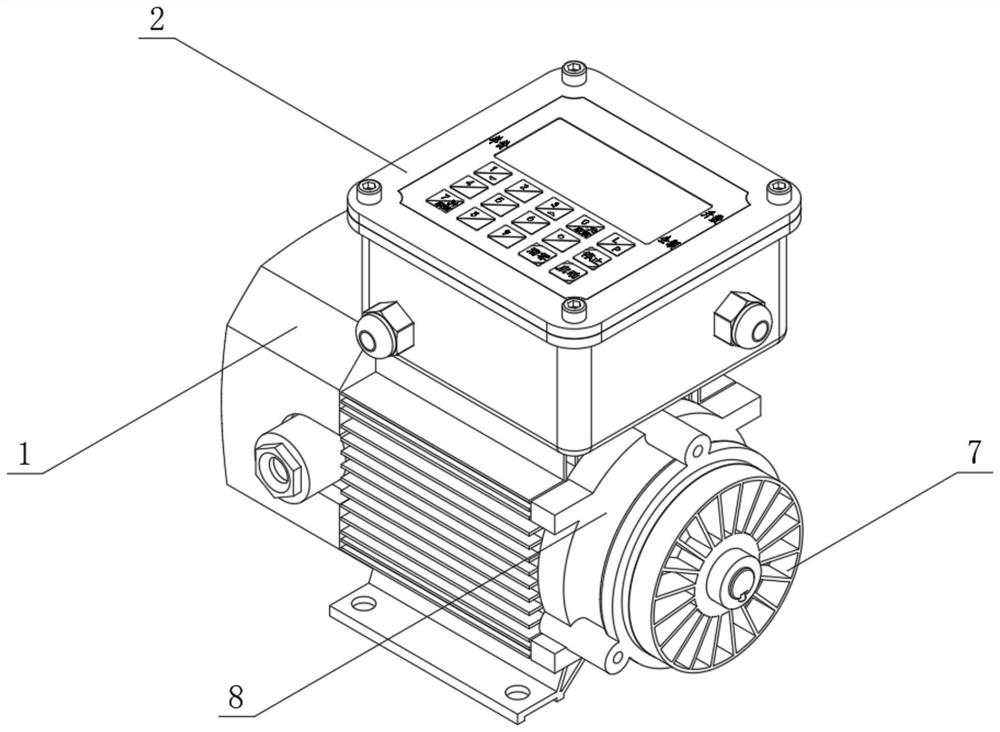

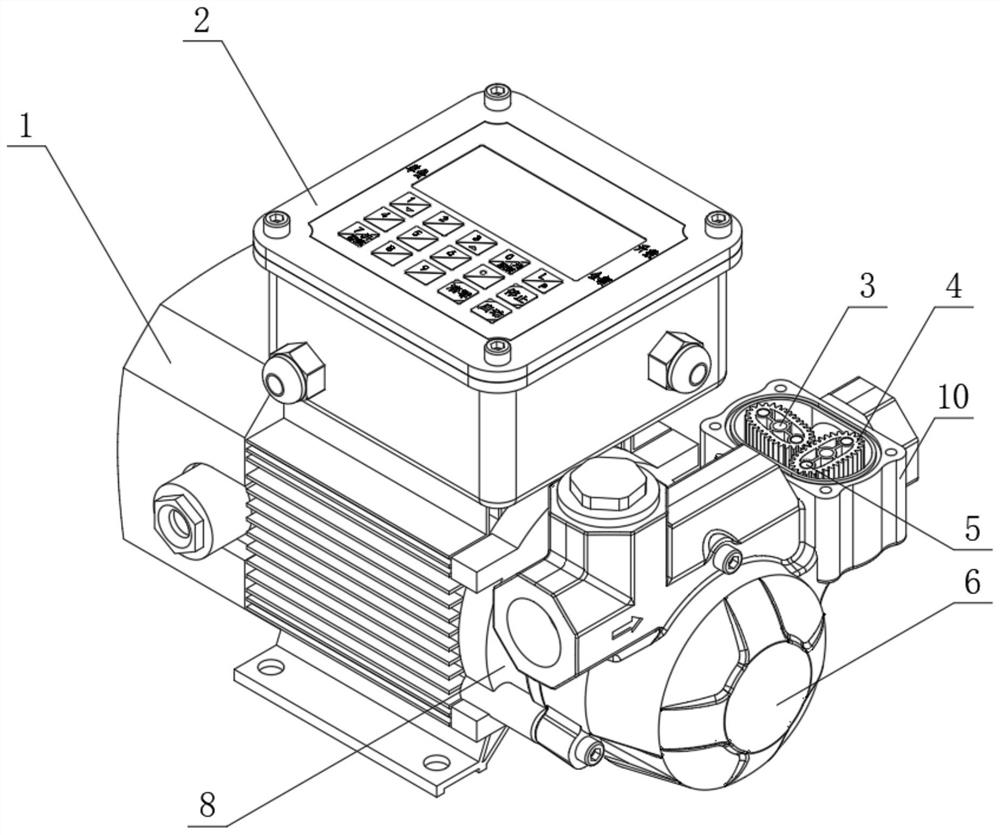

[0027] As an embodiment of the present invention, one side of the drive motor 1 is provided with a motor shaft, and one end of the motor shaft passes through the pump cover 8 and is fixedly connected to the aluminum alloy impeller 7, and is connected to the aluminum alloy impeller 7 through the motor shaft. When the motor 1 works, it drives the motor shaft to rotate, and then can drive the aluminum alloy impeller 7 to rotate, and the aluminum alloy impeller 7 rotates to complete the pumping action.

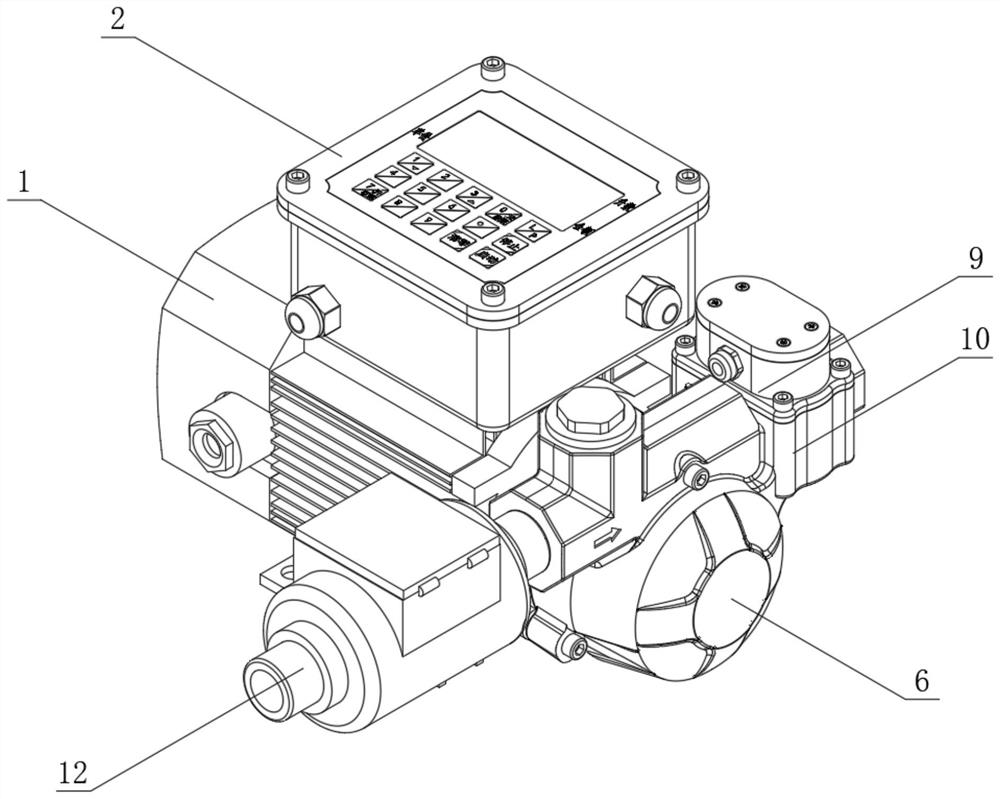

[0028] As an embodiment of the present invention, the outlet end of the pump body 6 is provided with a flow meter chamber, and the induction cover 10 is sealed and installed on the end face of the flow meter chamber. The through hole of the through hole communicates with the outlet end of the pump body 6, and the through hole at the other end of the induction cover 10 is connected with the outside world, which facilitates the communication of the oil circuit and facilitates oil del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com