Pressure swing adsorption hydrogen production process

A pressure swing adsorption and process technology, applied in the field of coal chemical industry, can solve the problems of vacuum pump power consumption, high water consumption, packing seal leakage, and affecting the operation of working conditions, so as to reduce the workload, reduce the sound of device operation, and improve safe operation index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

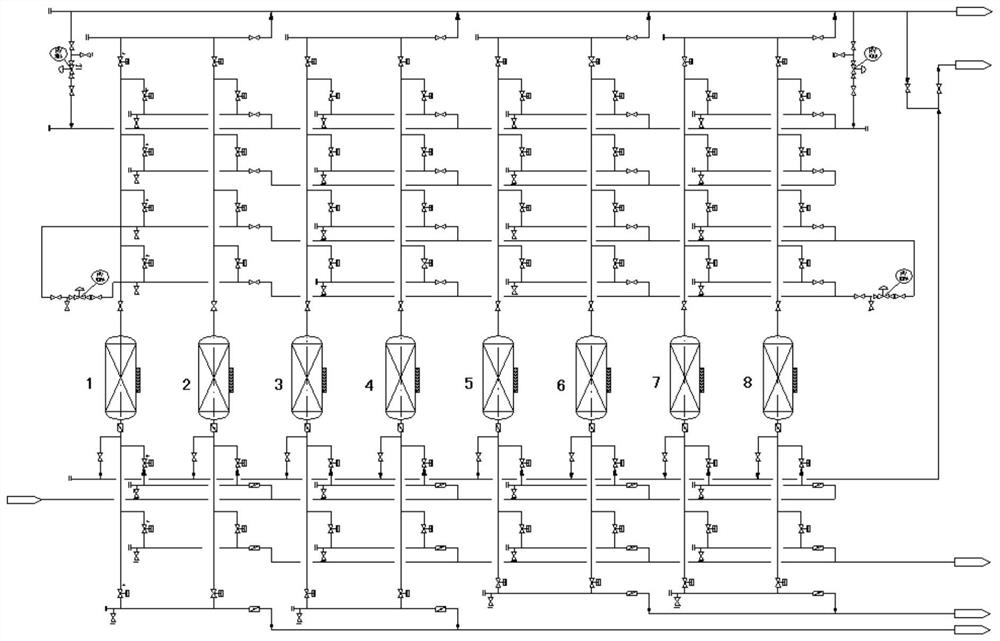

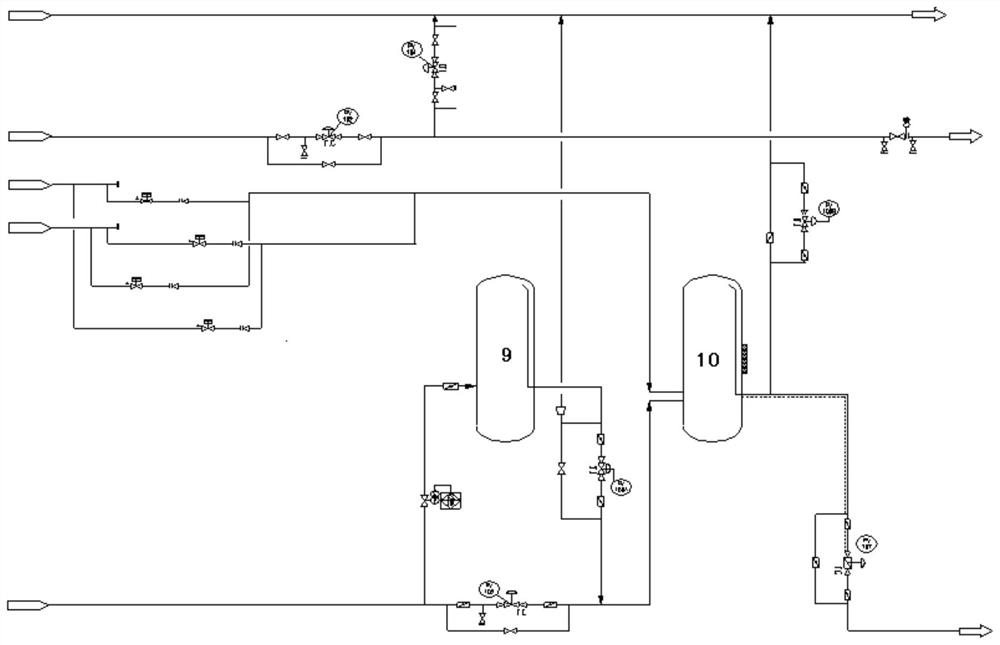

[0061] Feed gas (fresh synthesis gas, oil-washed dry gas) with a pressure of 2.0Mpa and a temperature of ≤40°C figure 1 and figure 2 The pressure swing adsorption system shown. The pressure swing adsorption system consists of 8 adsorption towers, 1 desorption gas buffer tank, 1 desorption gas mixing tank, 65 program-controlled valves and multiple regulating valves. The main process flow adopts 8-2-3 / P process, that is, 8 online working towers, 2 towers of adsorption, 3 times of pressure equalization, and washing and regeneration processes.

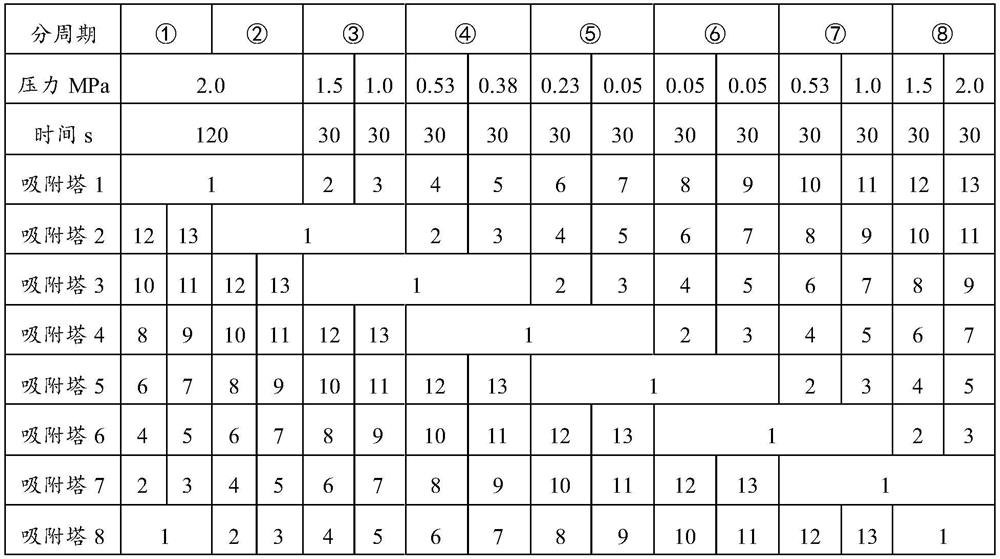

[0062] The specific operating parameters are shown in Table 1:

[0063]

[0064] In Table 1, 1 to 13 represent adsorption (1), first-stage pressure equalization drop (2), second-stage pressure equalization drop (3), third-stage pressure equalization drop (4), first forward discharge Pressure (5), second forward pressure release (6), reverse pressure release (7), first backwash (8), second backwash (9), third stage pressure equalizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com