Tripod type constant-velocity joint and image-forming device

A coupling and constant-velocity technology, which is applied in the field of speed couplings and image forming devices, can solve the problems of constant-speed rotation of photosensitive drums, tilting of photosensitive drums, assembly errors, etc., to achieve improved degrees of freedom, superior durability, and realization The effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

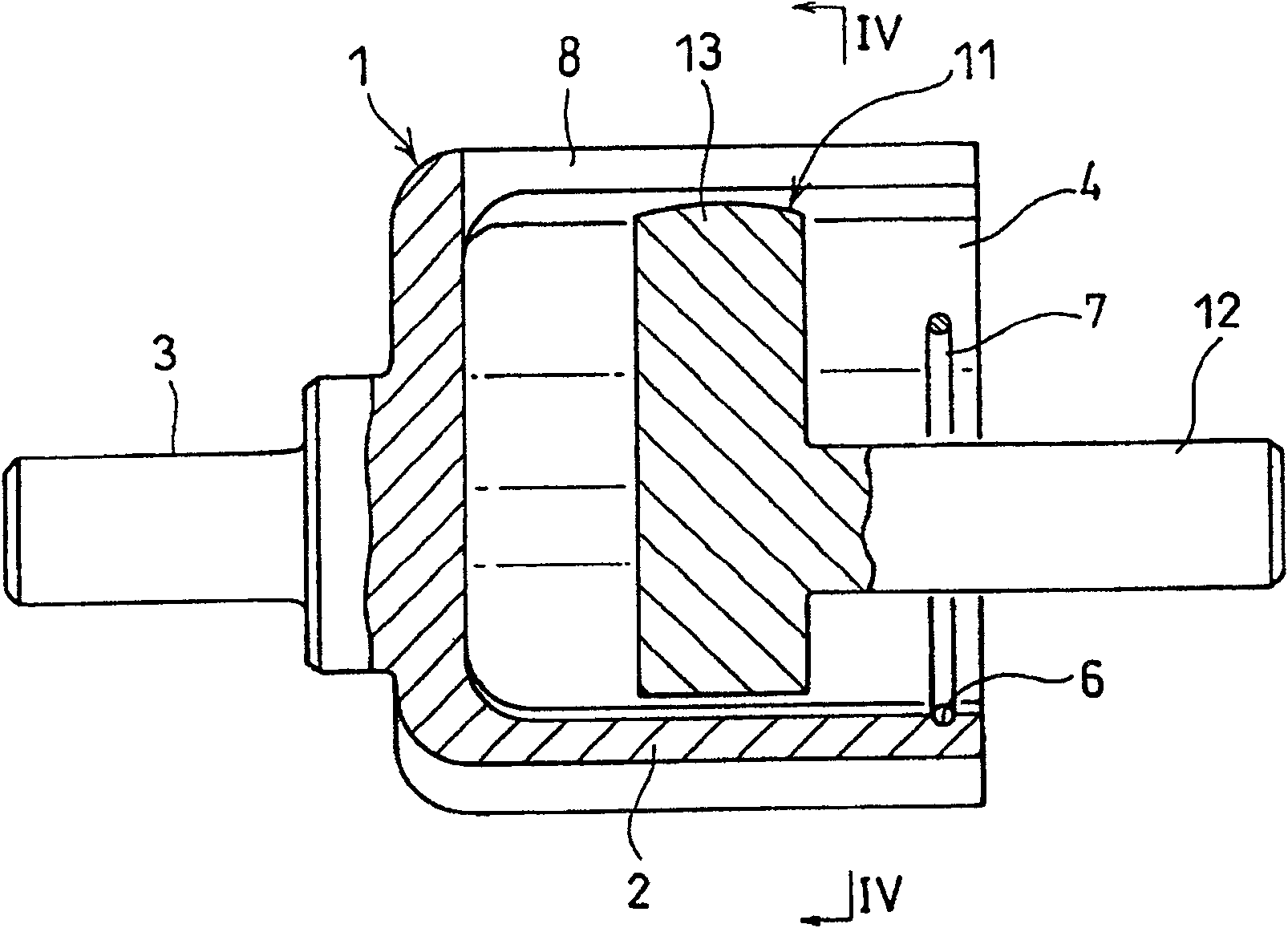

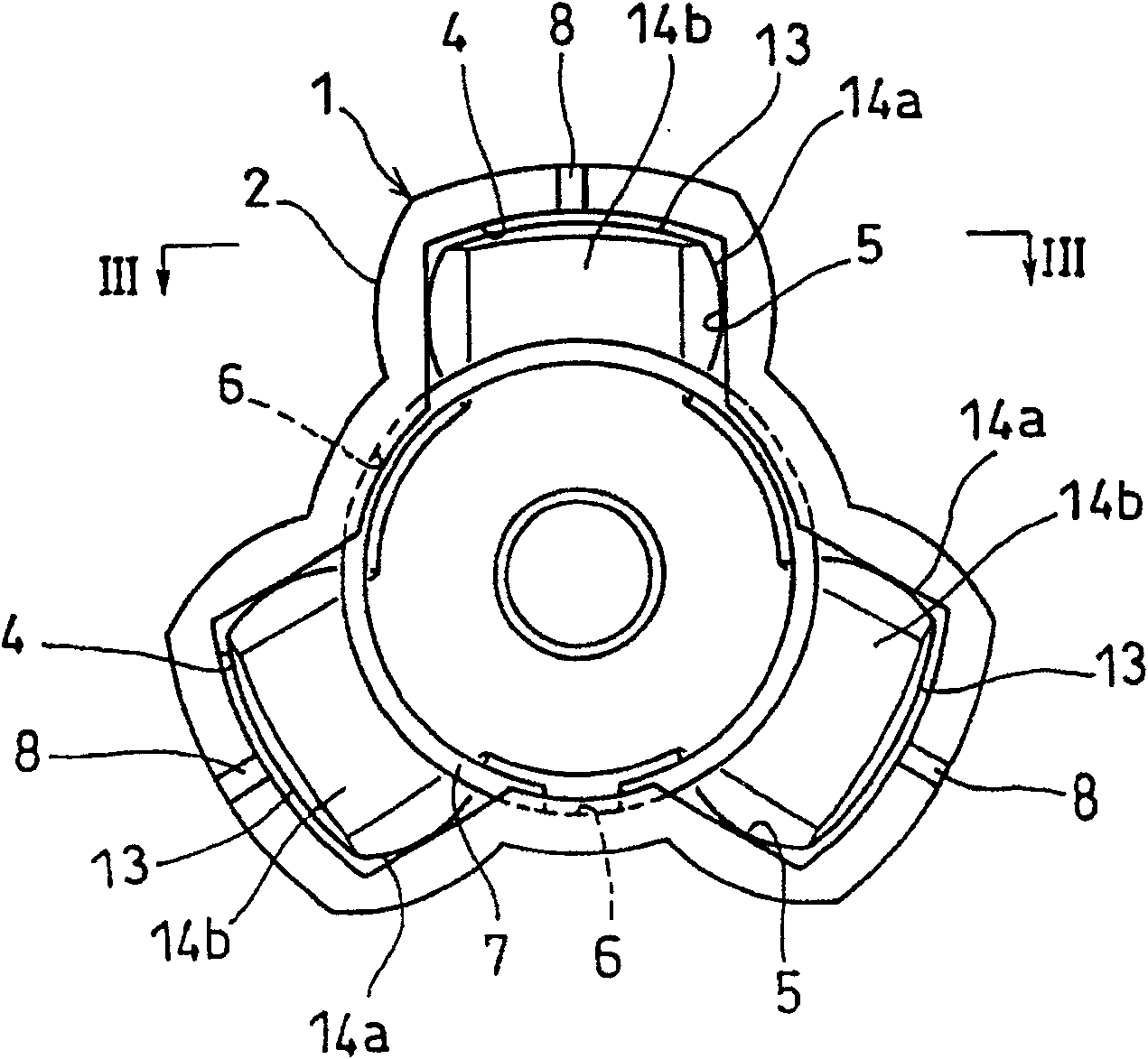

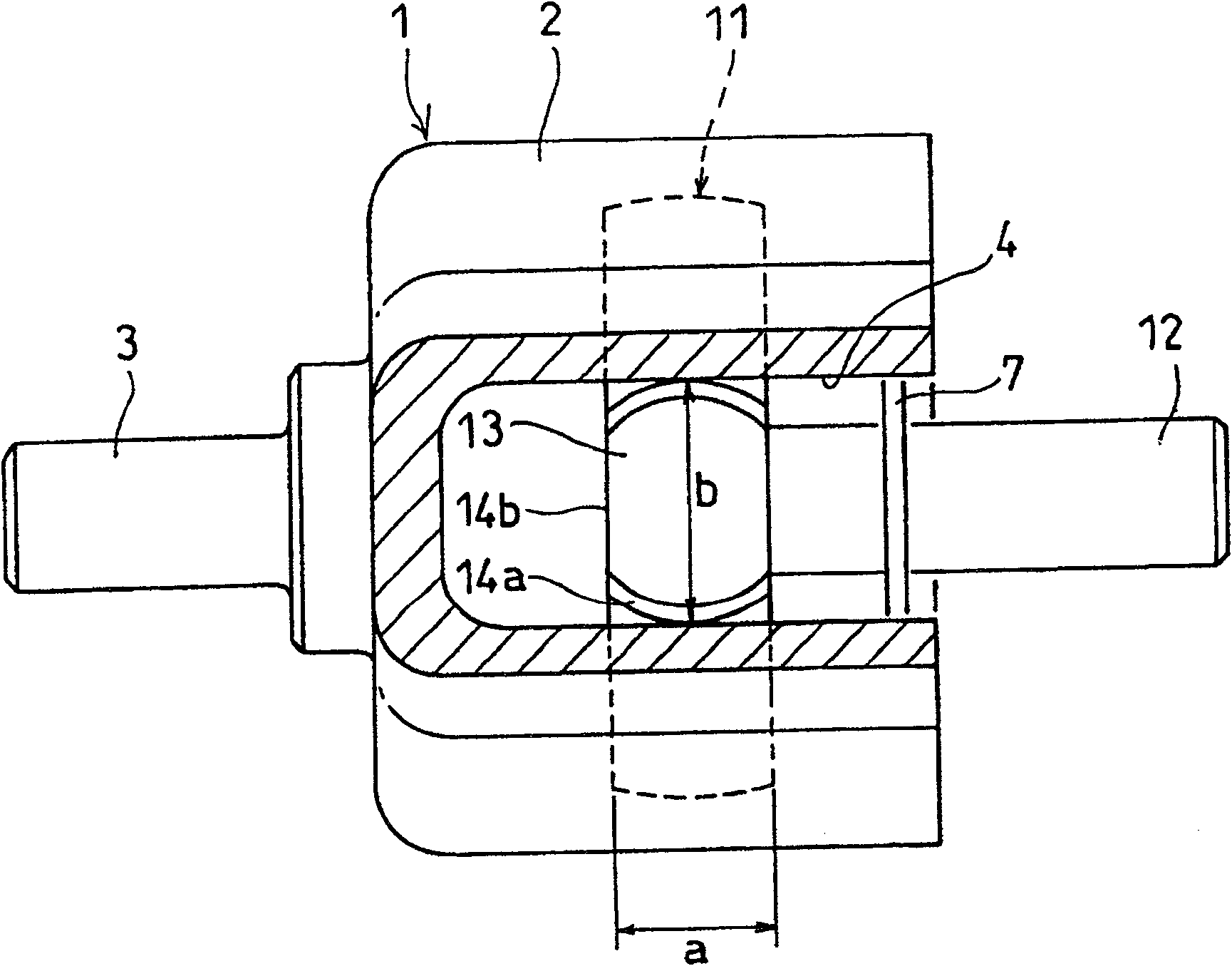

[0036] Embodiments of the present invention will be described below with reference to the drawings. Such as Figure 1 to Figure 4 As shown, the tripod constant velocity coupling is composed of an outer ring 1 and a tripod part 11 assembled inside it.

[0037] The outer ring 1 is configured such that a first shaft 3 is provided at the closed end of a cup-shaped portion 2 that is open at one end, and on the inner circumference of the cup-shaped portion 2 , there are formed shafts extending from the open end at intervals of 120° in the circumferential direction. Three track grooves 4 extending in the axial direction. A pair of side surfaces 5 opposing in the circumferential direction of the track groove 4 are flat surfaces parallel to each other.

[0038] The tripod member 11 has a second shaft 12 . Three protrusions 13 inserted into the respective track grooves 4 of the outer ring 1 are integrally provided on the tripod member 11 .

[0039] Each protruding portion 13 is free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com