Spherical coordinates boring machine

A drilling machine and spherical coordinate technology, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of difficult drilling processing, small clamping force area, and difficult clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0025] Unless otherwise expressly stated otherwise, throughout the specification and claims, the term "comprising" or its transformations such as "including" or "including" will be understood to include the stated elements or components, and not Other elements or other components are not excluded.

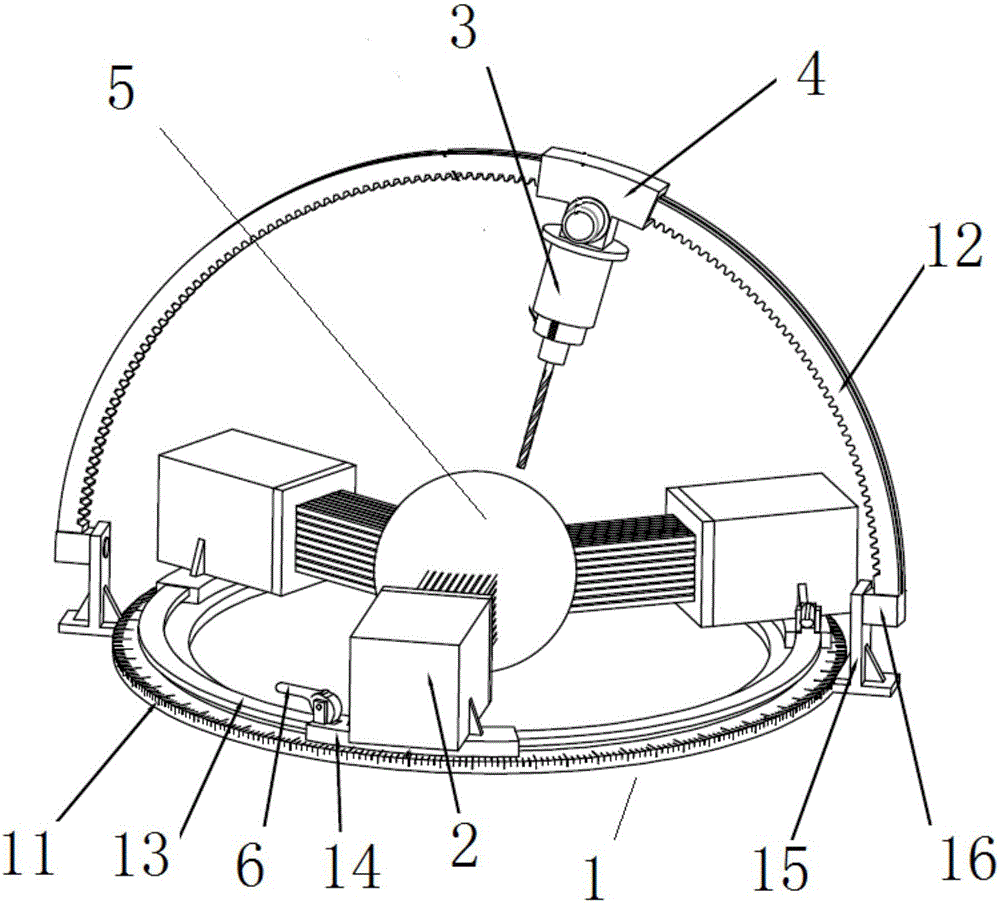

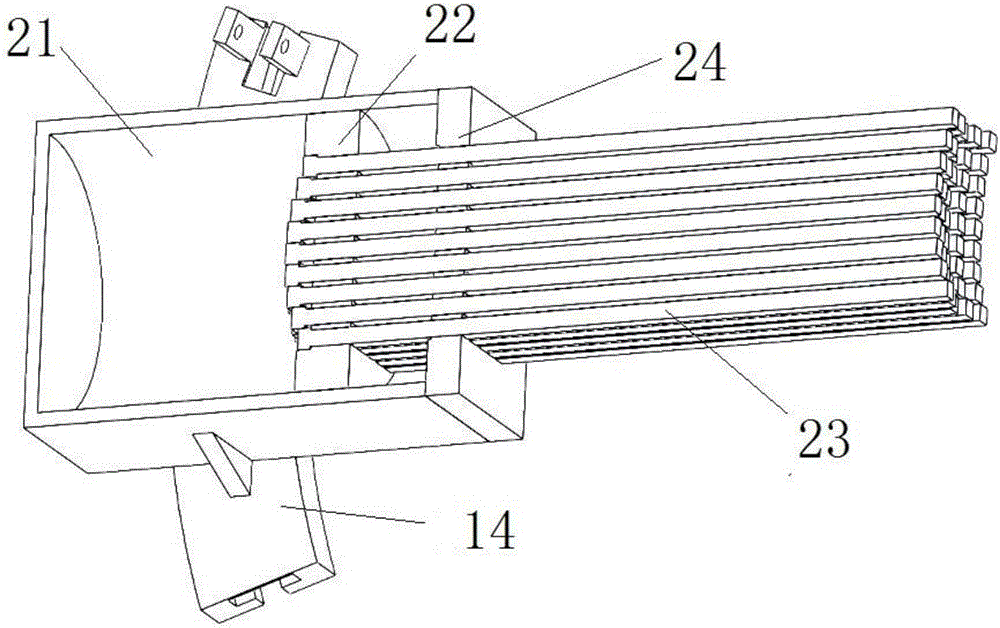

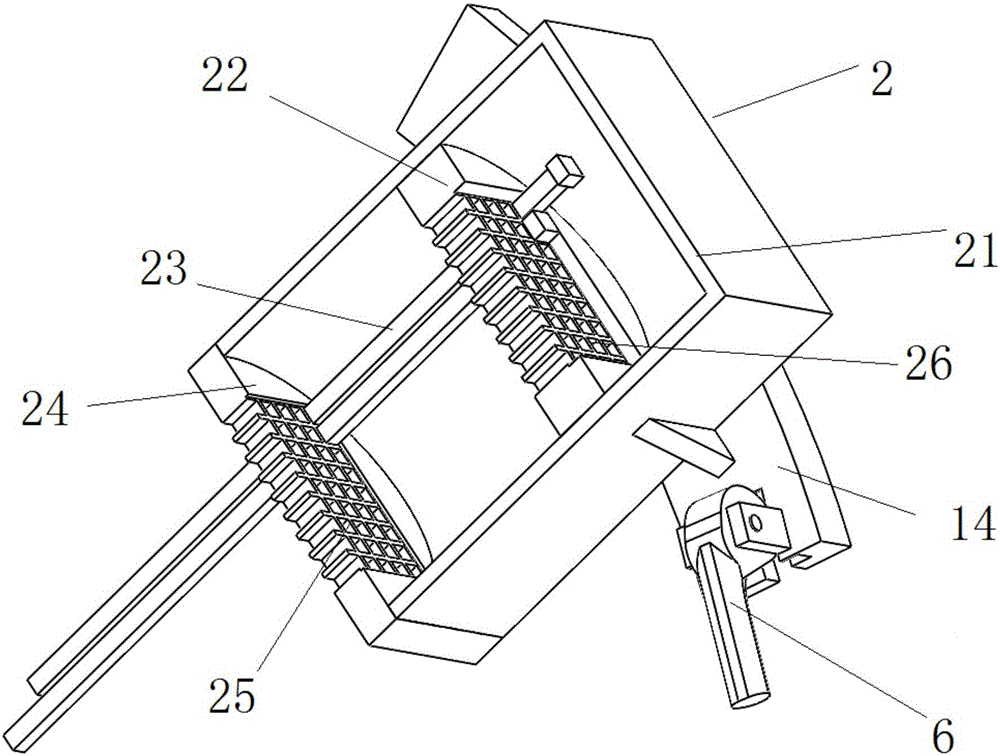

[0026] Such as Figure 1 to Figure 7 As shown, a spherical coordinate drilling machine according to a specific embodiment of the present invention includes: a spherical coordinate device 1, a clamp 2 and a tool assembly 3. The spherical coordinate device 1 includes a circular scale 11 and an annular guide 12, and the annular guide 12 is arranged on the circular scale 11 to be capable of reciprocating back and forth. The tool assembly 3 is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap