Double-station material automatic distribution and automatic fission system

A technology of automatic distribution and distribution system, which is applied to the removal of solid waste, conveyors, mechanical conveyors, etc., can solve the problems of secondary pollution, poor hygiene guarantee conditions for workers, and composting yard production shutdown, etc. The effect of promoting industrialized operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

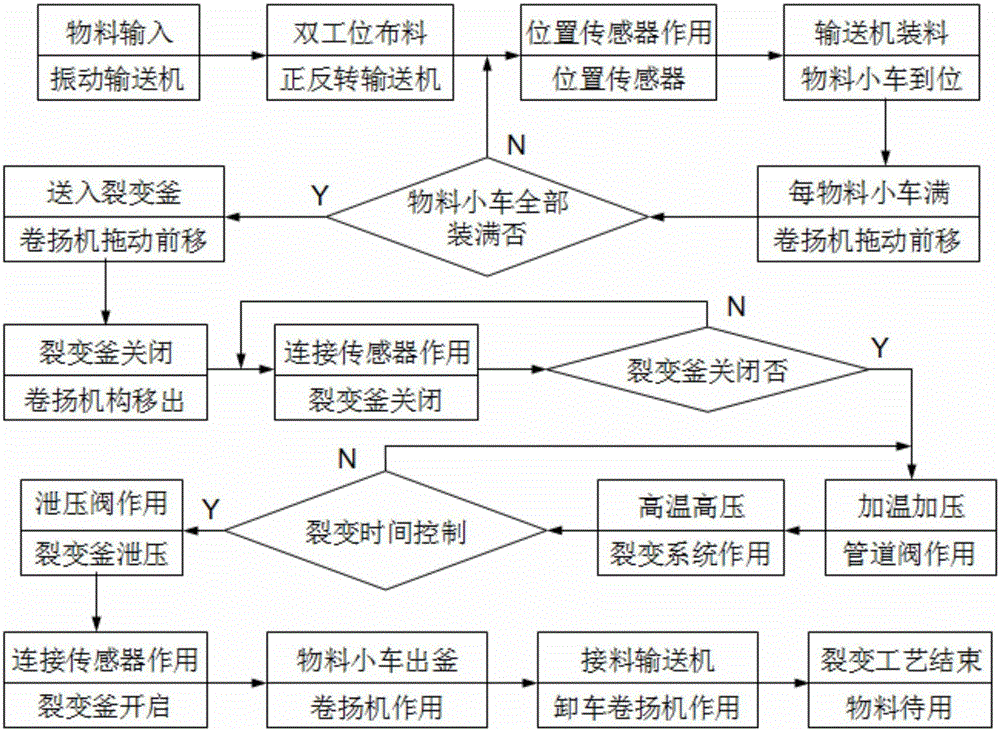

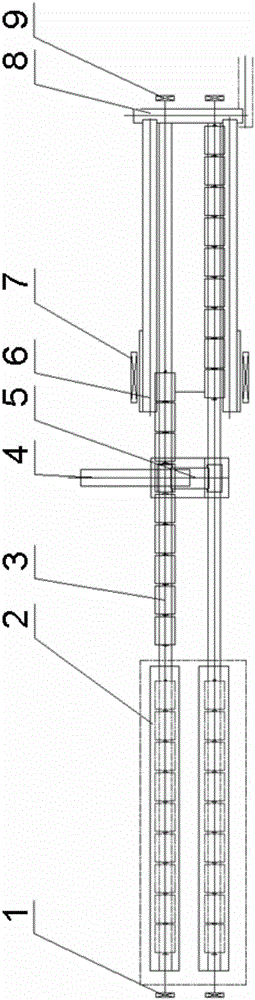

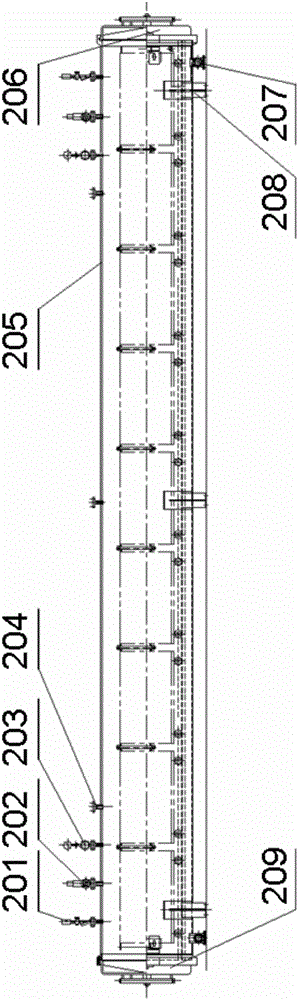

[0044] figure 1 Described the fission system technological process involved in the present invention, figure 2 It is the process equipment plane layout drawing of the present invention, combined with figure 1 , figure 2 As shown, the material double-station automatic distribution and automatic fission system provided by the present invention includes two sets of tracks arranged in parallel, one end of the two sets of tracks is a fission zone, the other end is a discharge zone, and the two ends are a distribution zone;

[0045] Each group of tracks is provided with a group of (the present embodiment is a group of nine) material trolleys 3 that can be connected in series, and one end of each group of material trolleys 3 is connected with a still hoist 1, and the other end is connected with a still hoist 9, so that The group of material trolleys 3 can switch positions between the fission zone, the material distribution zone and the unloading zone;

[0046] Corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com