Preparation method of acetone thiosemicarbazone and the prepared acetone thiosemicarbazone

A technology of acetone thiosemicarbazone and acetone is applied in the fields of medicine and pesticide compounds, which can solve the problems of low yield and low purity of finished products, and achieve the effect of high income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

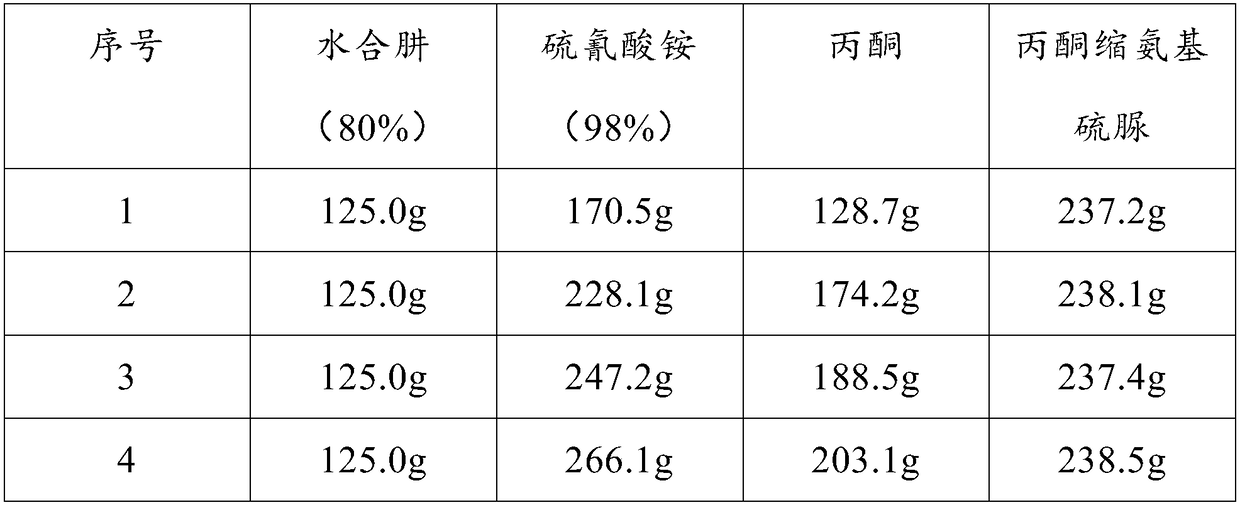

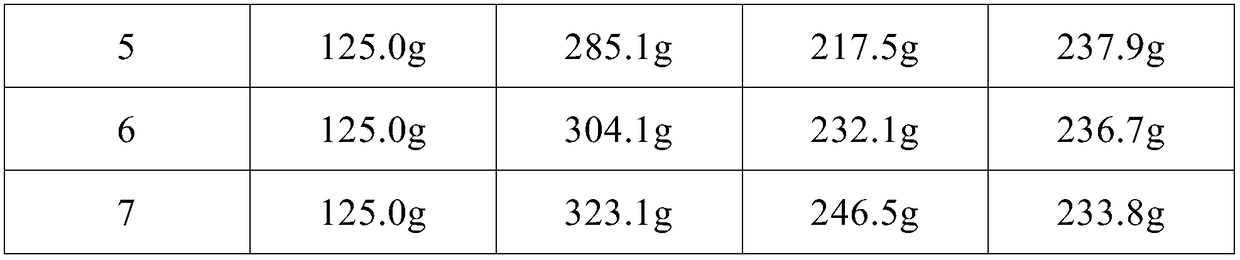

Examples

Embodiment 1

[0021] Embodiment one: the preparation method of a kind of acetone thiosemicarbazone disclosed by the present invention, comprises the following steps, (1) puts the raw material prepared in reactor, and raw material comprises water, hydrazine hydrate, ammonium thiocyanate;

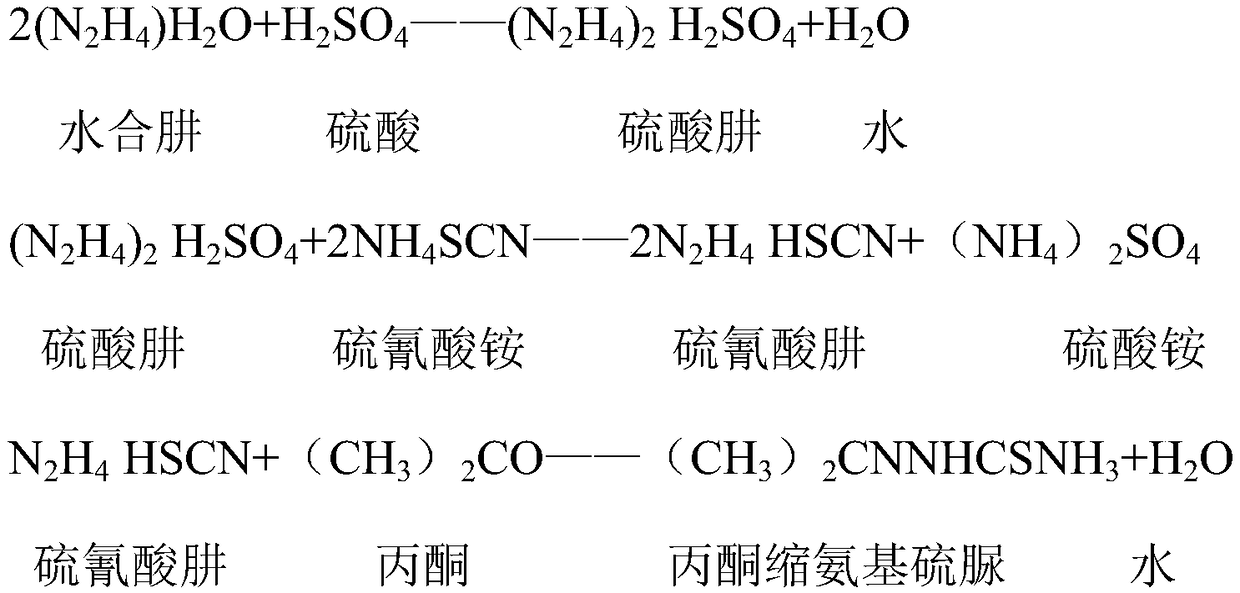

[0022] (2) Heating causes the raw materials to undergo a chemical reaction, and the chemical reaction equation is as follows:

[0023] (N 2 h 4 )H 2 O+NH 4 SCN→N 2 h 4 HSCN+NH 3 +H 2 O;

[0024] (3) When the temperature of reaction rose to 40°C, the reactor was evacuated to discharge the ammonia generated by the reaction;

[0025] (4) The reaction kettle is cooled, and when the temperature is lowered to 30° C., acetone is added in the reaction kettle;

[0026] (5) Acetone reacts exothermicly with hydrazine thiocyanate, and the chemical reaction equation is as follows:

[0027] N 2 h 4 HSCN+(CH 3 ) 2 CO——(CH 3 ) 2 CNNHCSNH 3 +H 2 o

[0028] (6) When the reaction temperature reaches 50° C....

Embodiment 2

[0032] Embodiment two: the preparation method of a kind of acetone thiosemicarbazone disclosed by the present invention, comprises the following steps, (1) puts the raw material prepared in the reactor, and raw material comprises water, hydrazine hydrate, ammonium thiocyanate;

[0033] (2) Heating causes the raw materials to undergo a chemical reaction, and the chemical reaction equation is as follows:

[0034] (N 2 h 4 )H 2 O+NH 4 SCN→N 2 h 4 HSCN+NH 3 +H 2 O;

[0035] (3) When the temperature of reaction rose to 50°C, the reactor was evacuated to discharge the ammonia generated by the reaction;

[0036] (4) The reactor is cooled, and when the temperature is lowered to 15° C., acetone is added into the reactor;

[0037] (5) Acetone reacts exothermicly with hydrazine thiocyanate, and the chemical reaction equation is as follows:

[0038] N 2 h 4 HSCN+(CH 3 ) 2 CO——(CH 3 ) 2 CNNHCSNH 3 +H 2 o

[0039] (6) When the reaction temperature reaches 80° C., a reflux...

Embodiment 3

[0045] Embodiment three: the preparation method of a kind of acetone thiosemicarbazone disclosed by the present invention, comprises the following steps, (1) puts the raw material prepared in the reactor, and raw material comprises water, hydrazine hydrate, ammonium thiocyanate;

[0046] (2) Heating causes the raw materials to undergo a chemical reaction, and the chemical reaction equation is as follows:

[0047] (N 2 h 4 )H 2 O+NH 4 SCN→N 2 h 4 HSCN+NH 3 +H 2 O;

[0048] (3) When the temperature of reaction rose to 45°C, the reactor was evacuated to discharge the ammonia generated by the reaction;

[0049] (4) The reaction kettle is cooled, and when the temperature is lowered to 35° C., acetone is added in the reaction kettle;

[0050] (5) Acetone reacts exothermicly with hydrazine thiocyanate, and the chemical reaction equation is as follows:

[0051] N 2 h 4 HSCN+(CH 3 ) 2 CO——(CH 3 ) 2 CNNHCSNH 3 +H 2 o

[0052] (6) When the reaction temperature reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com