Liquid crystal aligning agent, liquid crystal aligning film and manufacturing method thereof, and panel and device comprising same

A technology of liquid crystal aligning agent and liquid crystal aligning film, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of reduced screen contrast, high contrast, weak afterimage, etc., to reduce the amount of Dose, improve the alignment, improve the Effects of contrast and afterimages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] In one embodiment, the present invention also provides a method for preparing the aforementioned liquid crystal alignment film, the preparation method comprising the following steps:

[0101] (a) coating the aforementioned liquid crystal aligning agent on the substrate to form a coating film;

[0102] (b) pre-baking the substrate formed with the coating film;

[0103] (c) aligning the film layer obtained in step (b) by light, and then post-baking to form a liquid crystal alignment film.

[0104] In a preferred embodiment, the thickness of the coating film in step (a) is 80nm-120nm, such as 90nm, 100nm, 110nm and so on.

[0105] In a preferred embodiment, the baking temperature in the pre-baking stage of step (b) is 70-150°C, such as 90°C, 110°C, 130°C, etc., and the baking time is 120s.

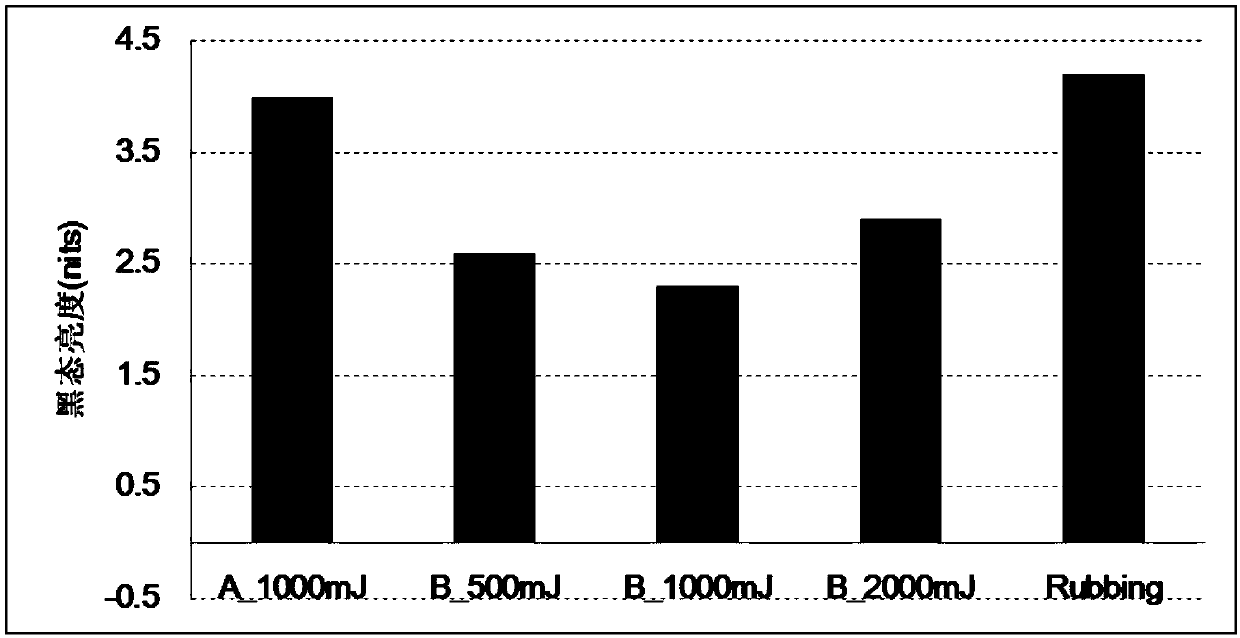

[0106] In a preferred specific embodiment, the wavelength range of the light alignment in step (c) is 254-323 nm, and the light alignment dose is 500-2000 mJ, such as 1000 mJ, 1500 m...

Embodiment 1

[0113] A liquid crystal aligning agent comprises the following components in parts by weight:

[0114] (i) have structure of polyamic acid, where n 1 The average value is 10.0, and the addition amount is 3 parts by weight;

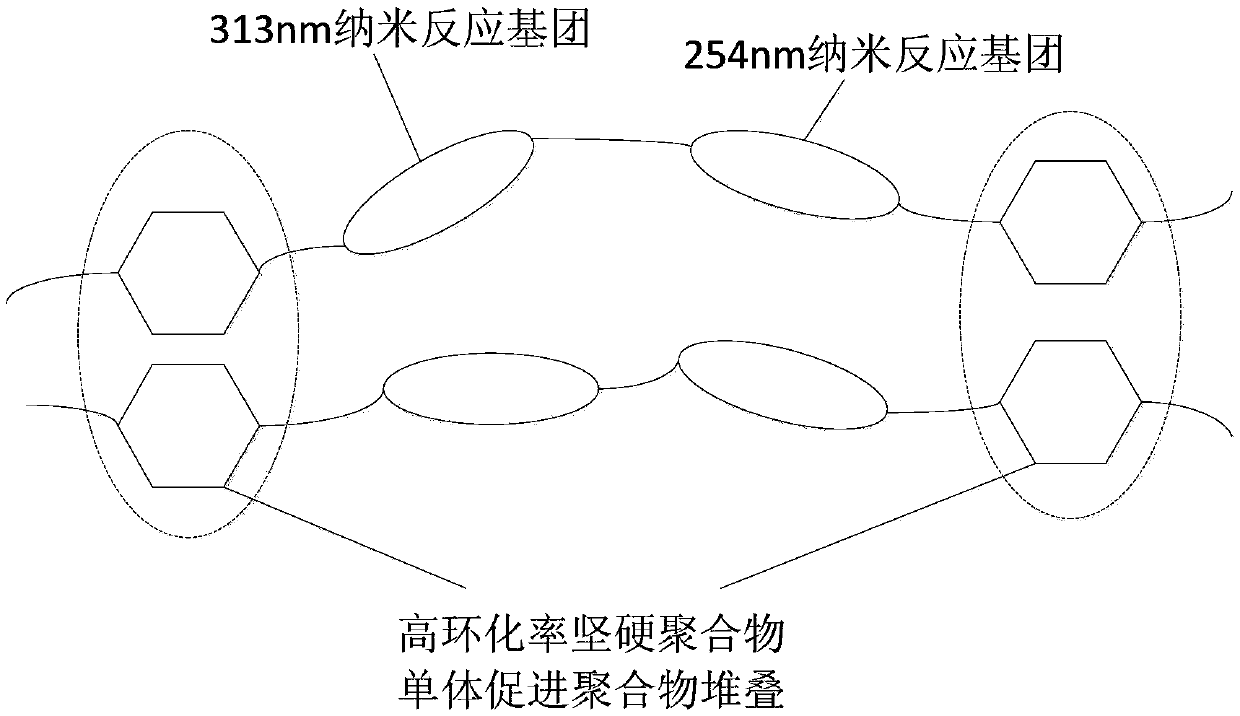

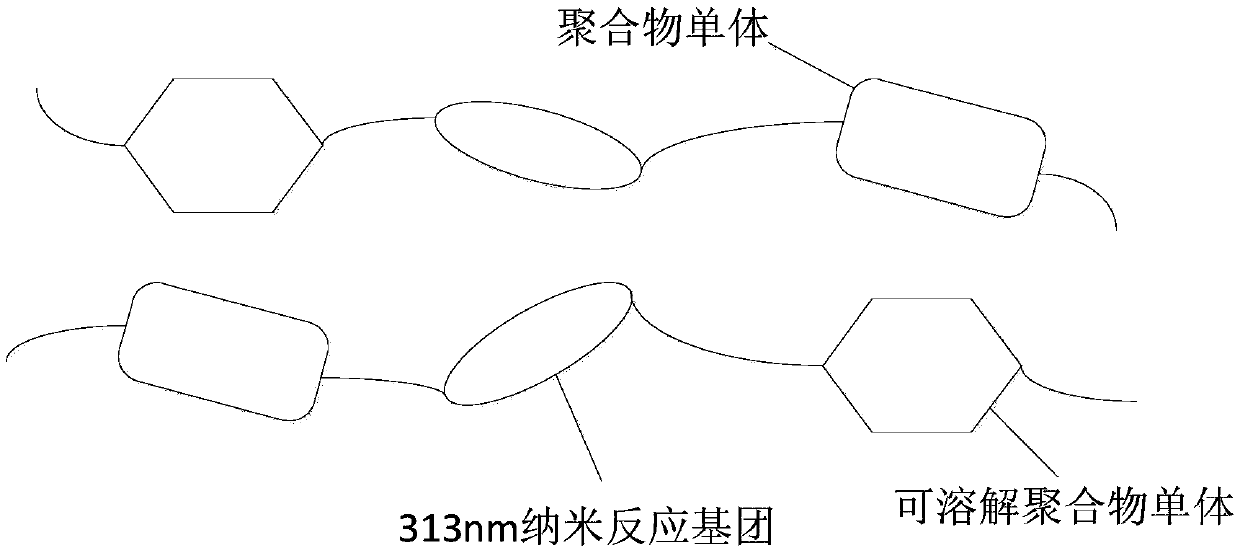

[0115] (ii) have structure of polyamic acid, where n 2 The average value is 9.3, and the addition amount is 1 part by weight; wherein the polypyrrole group is a rigid group, which belongs to a hard polymer group with a high cyclization rate, and can promote the stacking of the polymer in the obtained PI film;

[0116] (iii) have structure of polyamic acid, where n 2 The average value is 7.5, and the addition amount is 1 part by weight; an isomeric photoreactive group is connected to it, which can be sensitive to a wavelength near 313nm;

[0117] (iv) have structure of polyamic acid, where n 2 The average value is 8.0, and the addition amount is 1 part by weight; a decomposing photoreactive group is connected to it, which can be sensitive to a w...

Embodiment 2

[0125]The difference from Example 1 is that the light alignment dose in step (c) is 500mJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com