Automatic electric control comviend laser cutting, etching and embroidery system and calibration method

A laser cutting and combined technology, applied in the direction of automatic control embroidery machines, laser welding equipment, embroidery machines, etc., can solve the problem of time loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

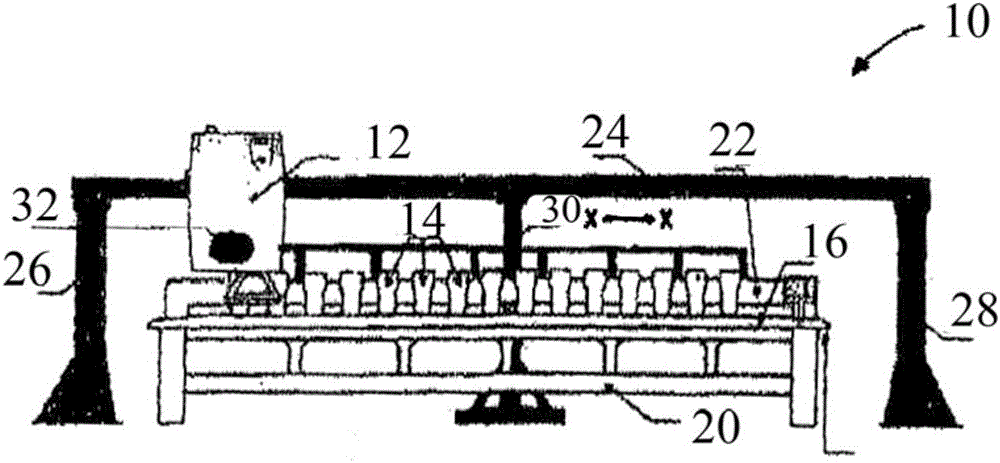

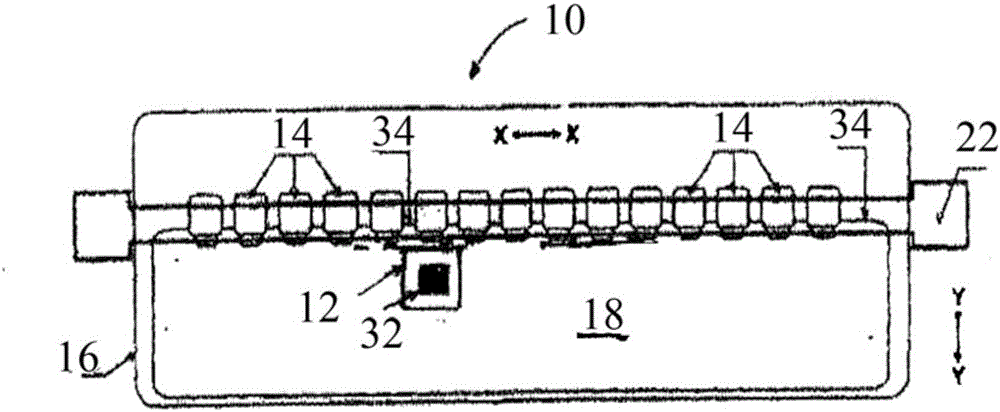

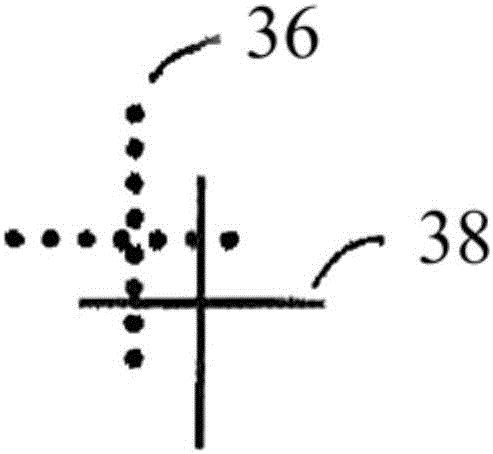

[0041] figure 1 and figure 2 A combined system 10 for laser cutting, engraving and embroidery is shown diagrammatically. The system consists of an electronically controlled automatic embroidery machine equipped with a laser cutting and engraving device 12 . Laser cutting and engraving devices are suitable for cutting and engraving operations on various materials at pre-set positions according to pre-set shapes and sizes. These materials include fabric, cloth, leather, cork and other similar materials that can be embroidered and laser processed, hereinafter referred to as "substrate". These substrates are embroidered by the associated embroidery head 14 built into the embroidery machine.

[0042] The embroidery machine actually comprises an elongated horizontal straight plate 16 on which a support 34 is defined on the horizontal working platform 18 . Different substrates are placed on this working platform. The horizontal bar 16 is supported by a support structure 20 stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com