An in-situ calibration device for solid rocket motor ground rotation test

A technology of rotation test and in-situ calibration, which is applied in the direction of engine test, measuring device, machine/structural component test, etc., to achieve the effect of high-precision calibration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

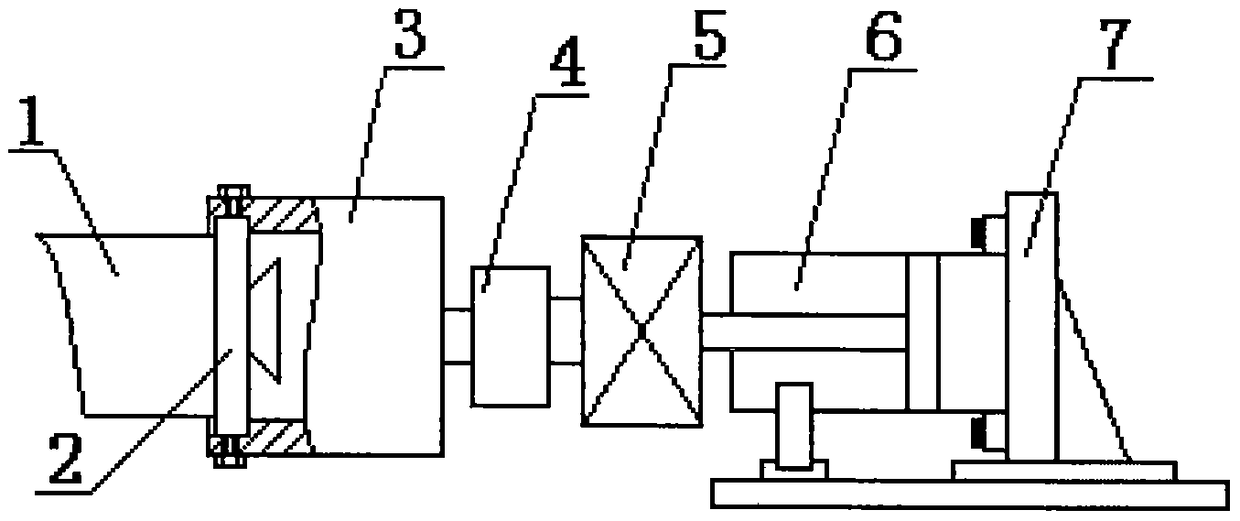

[0025] Such as figure 1 As shown, the solid rocket motor 1 is fixedly installed on the existing solid rocket motor rotation test device, the solid rocket motor tail skirt 2, the adapter device 3, the universal flexible part 4, the standard sensor 5, the force source loading device 6, the bearing The force piers 7 are connected coaxially in sequence.

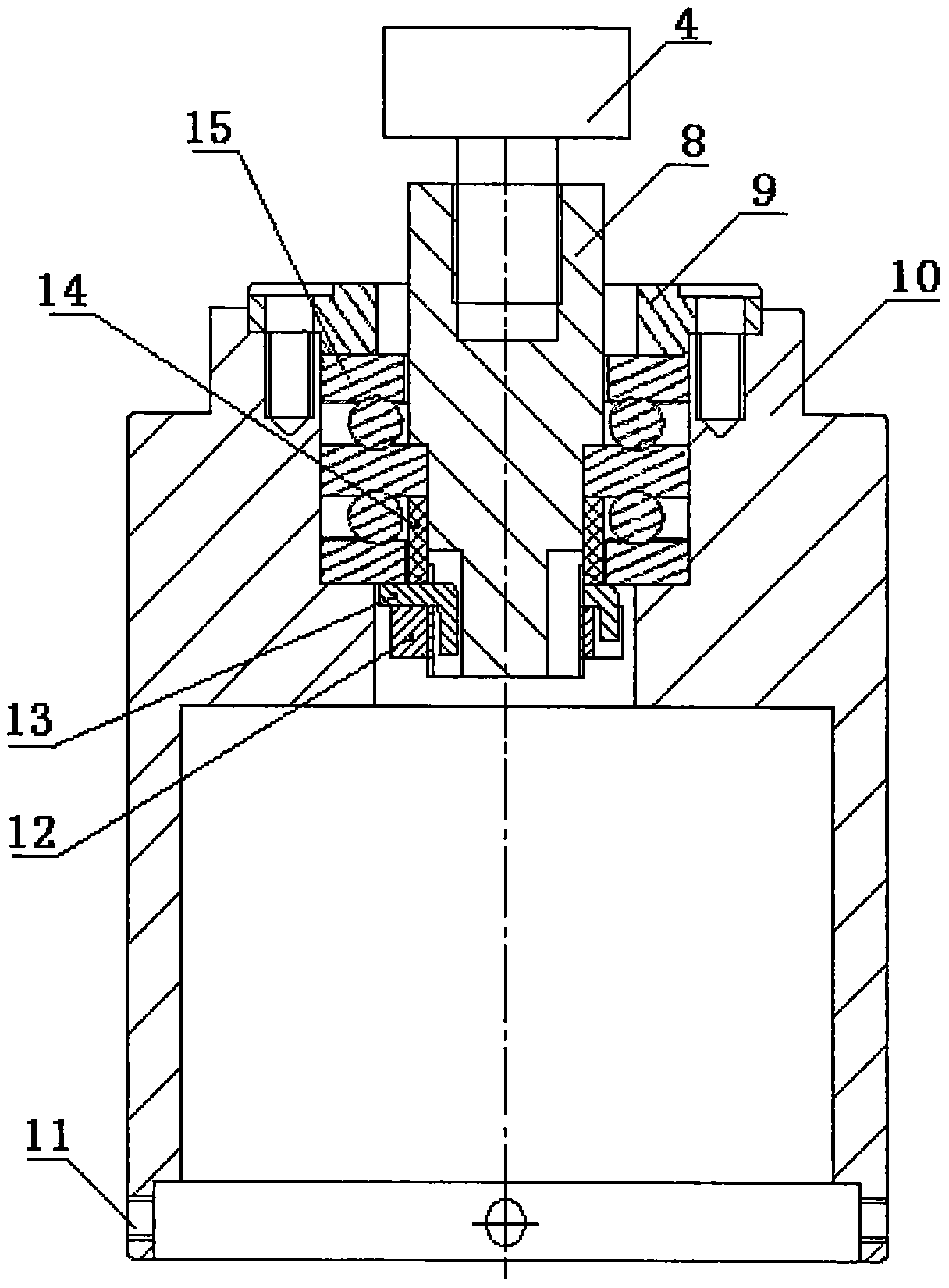

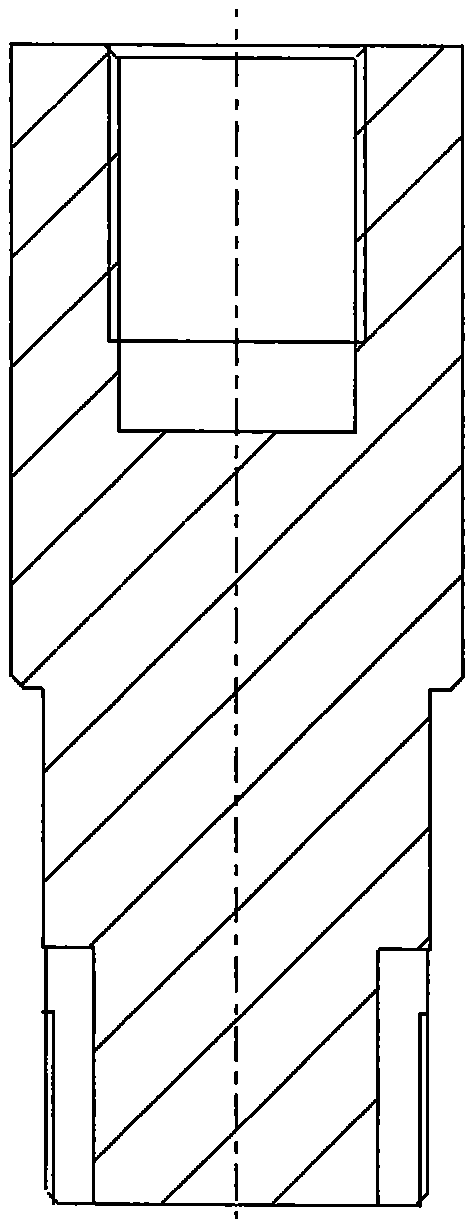

[0026] Such as figure 2 , image 3 with Figure 4 As shown, the load-bearing shaft 8 is a stepped cylinder, and the large-diameter end of the load-bearing shaft 8 is provided with an internally threaded blind hole, which is used to connect with the universal flexible part 4, and the universal flexible part 4 is connected with the standard The sensor 5 is connected coaxially, and the force source loading device 6 applies a simulated thrust force to the bearing shaft 8 . The small-diameter end of the load-bearing shaft 8 runs through the thrust ball bearing 15, and the step at the transition between the large-diameter end and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com