Method for eliminating high temperature fault of antiskid brake control device

A technology of anti-skid brakes and control devices, applied in the direction of program control, general control system, control/regulation system, etc., can solve the problems of increased weight, limited product weight, expensive thermal conductivity materials, etc., to save resources and energy, eliminate Effects of high temperature failure and improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

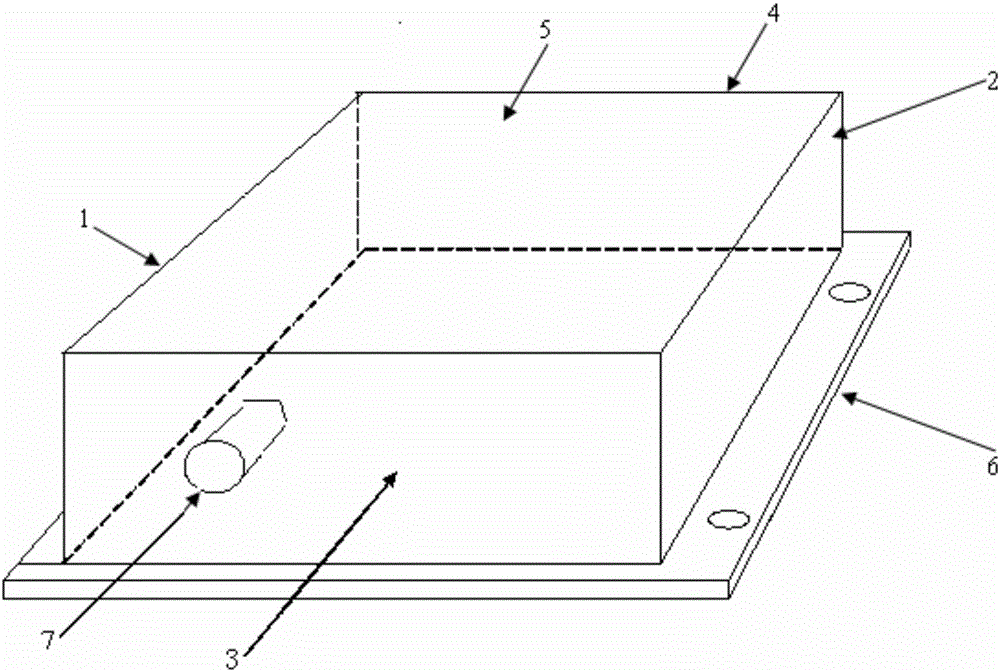

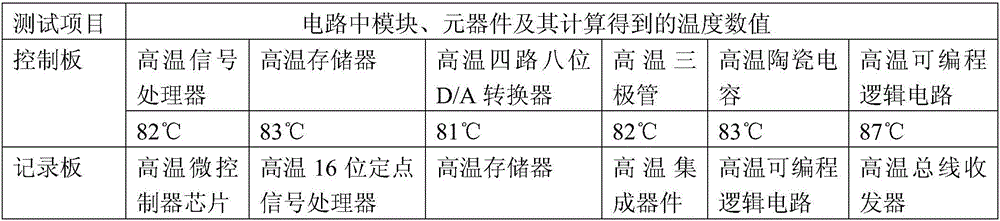

[0072] This embodiment is to improve the design of a high-temperature weak link of a civil aircraft anti-skid brake control device. The high-temperature weak link is a component that exceeds 100°C under the condition of an ambient temperature of 70°C. The invention adopts the design measures of improving the heat dissipation capacity, and prolongs the service life of the antiskid brake control device under high temperature conditions.

[0073] The purpose of this embodiment is that when the ambient temperature is 70°C and the anti-skid brake control device is working, the temperature of the casing and all components is lower than 100°C, so as to ensure that all components can work normally during use.

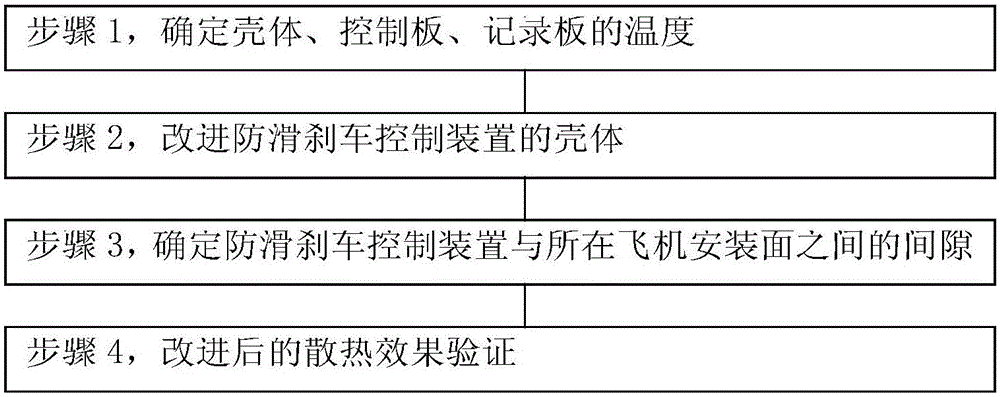

[0074] The technical solution of this embodiment is to adopt heat dissipation design measures for the housing and component layout of the anti-skid brake control device to improve the heat dissipation capacity of the anti-skid brake control device and achieve the purpose of redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com