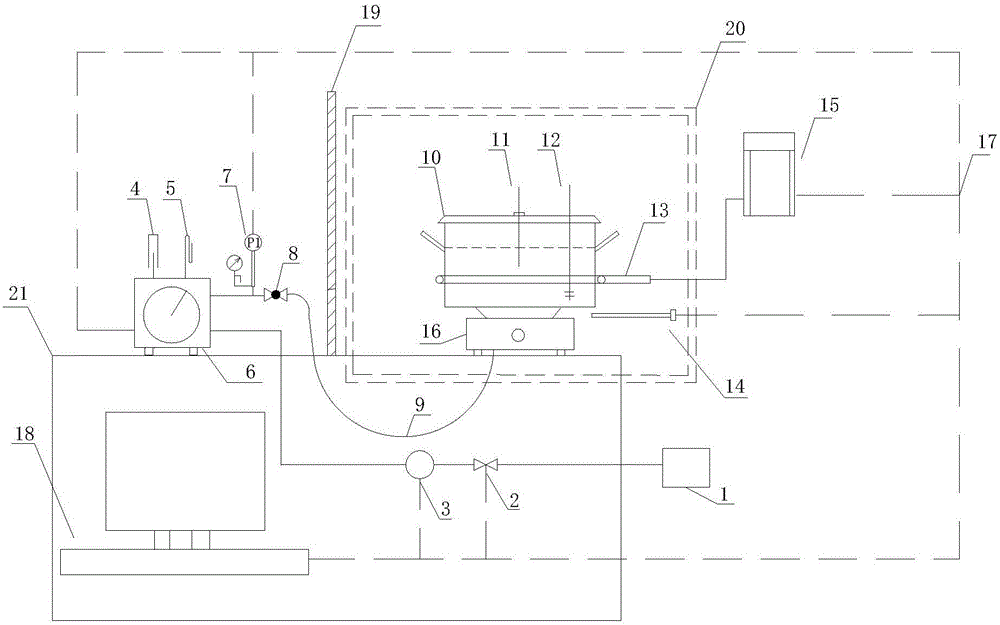

Gas cooking appliance optimization design evaluation method and test system therefor

A gas cooker, optimization design technology, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as unfavorable gas cooker burner research and development, time and resource consumption, human capital waste, etc., to achieve The effect of improving design efficiency and technical level and saving experimental time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in combination with specific embodiments.

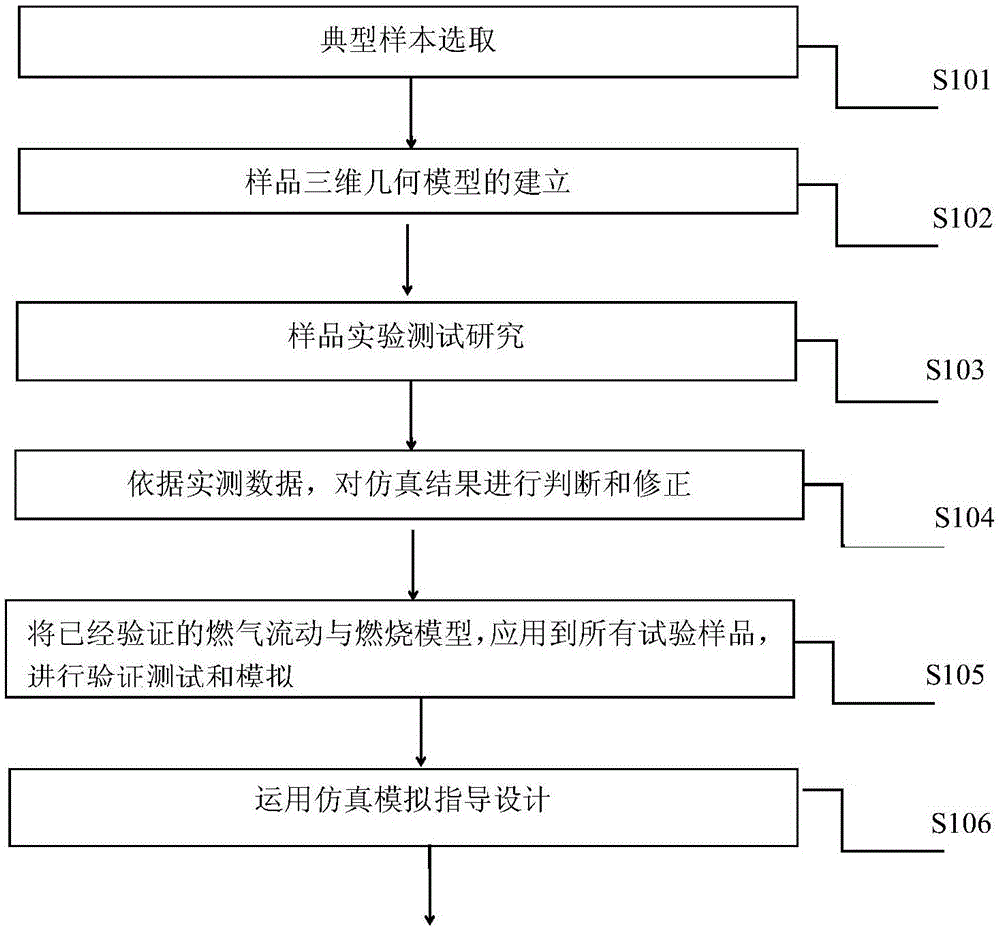

[0035] Such as figure 2 Shown: a technical method for optimizing design evaluation of a gas cooker, including the following steps:

[0036] 1) Step S101 typical sample selection:

[0037] a. Establish a three-dimensional geometric model of the experimental pot, and determine the basic size of the experimental pot according to the test standard GB 16410 "Household Gas Cooker". For example, for a certain sample: a cooker with a rated power of 4kW, the diameter of the pot is 300mm, the thickness of the pot wall is 0.8mm, the height is 190mm, and the heating water volume is 5kg.

[0038] b. Establish the three-dimensional geometric model of the stove burner, and parameterize the main design dimensions. The main design parameters are the size and shape of the ejector, the area of the fire cover, the type of fire hole, the size of the fire hole, the arrangement of the fire h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com