Nutritive breakfast bag based on soybean milk maker

A nutritious breakfast and soybean milk machine technology, applied in milk substitutes, dairy products, applications, etc., can solve the problems of strong throat sensation, high energy consumption, single taste and nutritional components, etc., and achieve the effect of strong bean flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Formulation:

[0071] Soy 40%

[0072] Instant Oats 13%

[0073] Corn grits 13%

[0074] Raw almond 13%

[0075] Dehydrated Dried Jujube 19%

[0076] Dried tremella 2%.

[0077] 2. Process flow

[0078] Soybeans were baked at 90°C for 15 minutes, soaked in 1.5% NaHCO3 solution for 1 minute, then quick-frozen at -18°C until the temperature inside and outside the whole soybean was consistent, and then baked at 85°C for 30 minutes. Mix the processed soybeans with the raw materials of the corresponding formula and evenly disperse them, then pour them into the soymilk machine, add 900mL of tap water, and press the button for making soymilk that comes with the soymilk machine to beat.

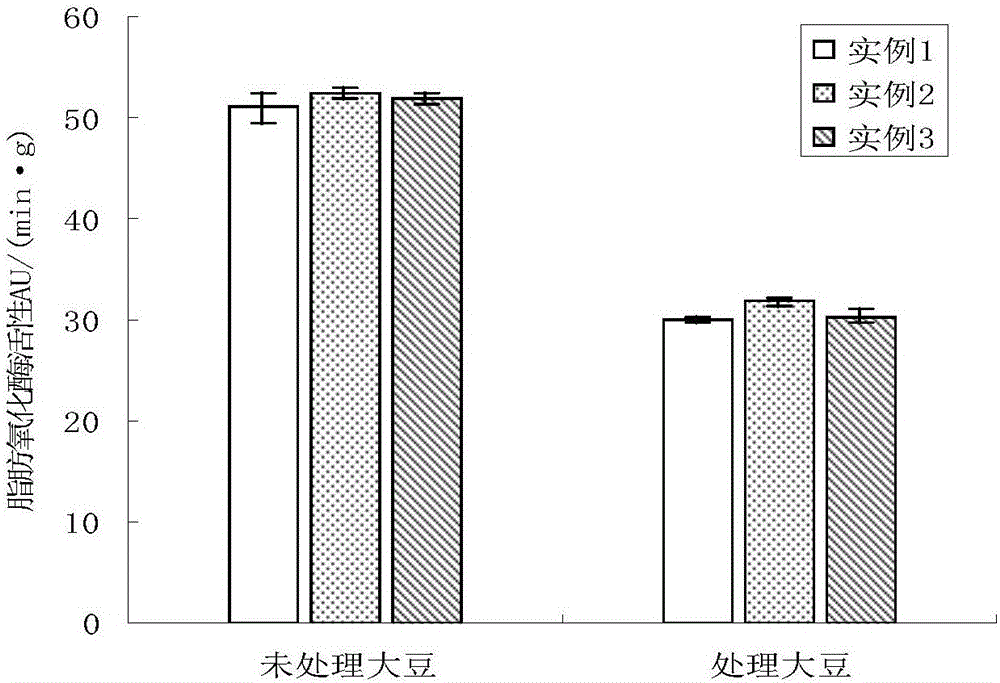

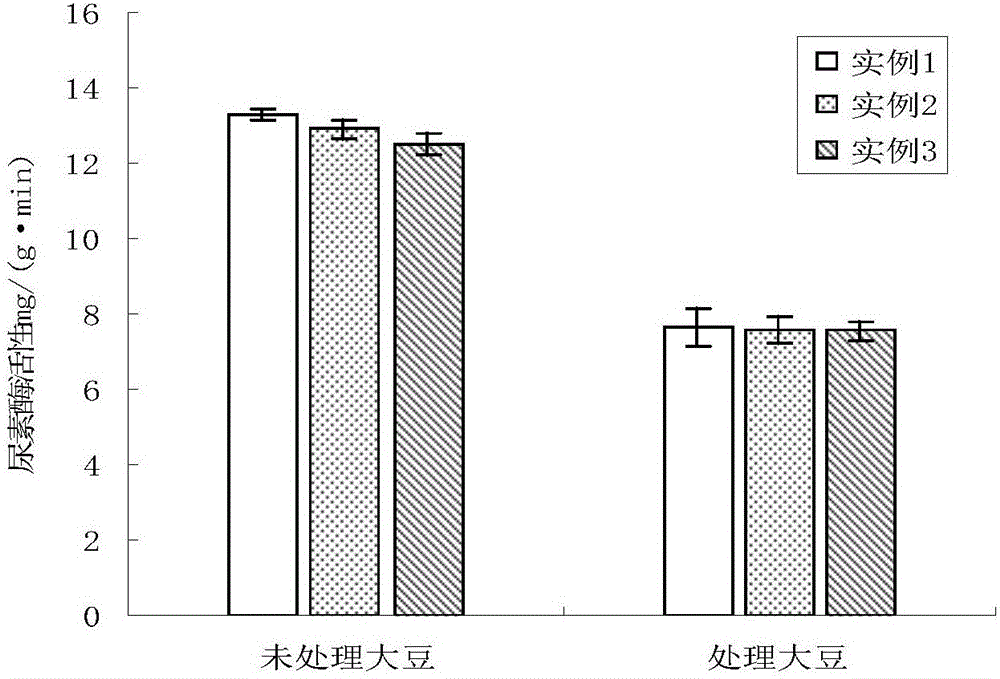

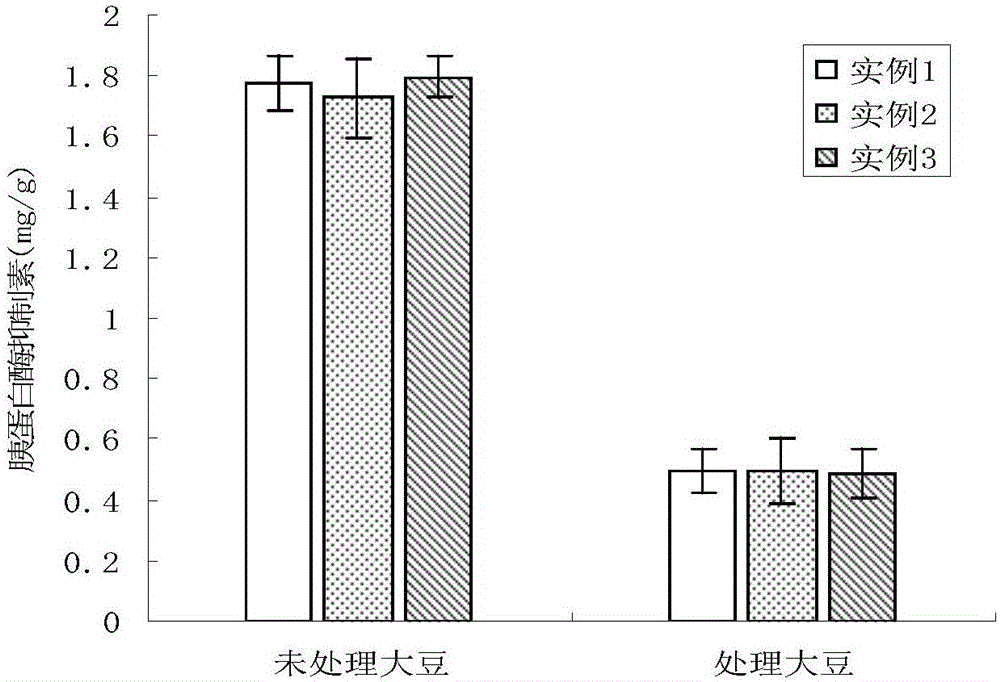

[0079] 3. Evaluation method and results

[0080] Test the distribution particle size D[4,3] (μm) of the suspended particles in the slurry (volume weighted average particle size refers to a quantity reflecting the average particle size of the system obtained by volume weighted average...

Embodiment 2

[0082] 1. Formulation:

[0083] Soy 50%

[0084] Instant Oats 10%

[0085] Corn grits 10%

[0086] Raw almond 10%

[0087] Dehydrated Dried Jujube 17%

[0088] Dried tremella 3%

[0089] 2. Process flow

[0090] Soybeans were dried with hot air at 110°C for 5 minutes, soaked in 1% NaHCO3 solution for 90s, then quick-frozen at -18°C until the temperature inside and outside the whole soybean was consistent, and then baked at 95°C or dried with hot air for 20 minutes. Mix the processed soybeans with the raw materials of the corresponding formula and evenly disperse them, then pour them into the soymilk machine, add 900mL of tap water, and press the button for making soymilk that comes with the soymilk machine to beat.

[0091] 3. Evaluation method and results

[0092] Test the distribution particle size D[4,3] (μm) of the suspended particles in the slurry (volume weighted average particle size refers to a quantity reflecting the average particle size of the system obtained...

Embodiment 3

[0094] 1. Formulation:

[0095] Soy 40%

[0096] Instant Oats 13%

[0097] Corn grits 13%

[0098] Raw almond 13%

[0099] Dehydrated Dried Jujube 19%

[0100] Dried tremella 2%

[0101] 2. Process flow

[0102] Soybeans were soaked at 20°C for 7 hours at a soybean liquid ratio of 1:5. The soaking solution is distilled water with 0.3% NaHCO added 3 made. The soaked soybeans are spread on a baking tray in a single layer and placed in an oven, and baked at a baking temperature of 75° C. for 6 hours. Mix the processed soybeans with the raw materials of the corresponding formula and evenly disperse them, then pour them into the soymilk machine, add 900mL of tap water, and press the button for making soymilk that comes with the soymilk machine to beat.

[0103] 3. Evaluation method and results

[0104] Test the distribution particle size D[4,3] (μm) of the suspended particles in the slurry (volume weighted average particle size refers to a quantity reflecting the average ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com