Seamless silk stockings and production process thereof

A seamless, stocking technology, applied in socks, pantyhose, clothing and other directions, can solve the problems of stitch marks, pimple touch, and smear marks at the contact position at the splicing point, achieve enhanced coverage, avoid excessive mesh, The effect of preventing oppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

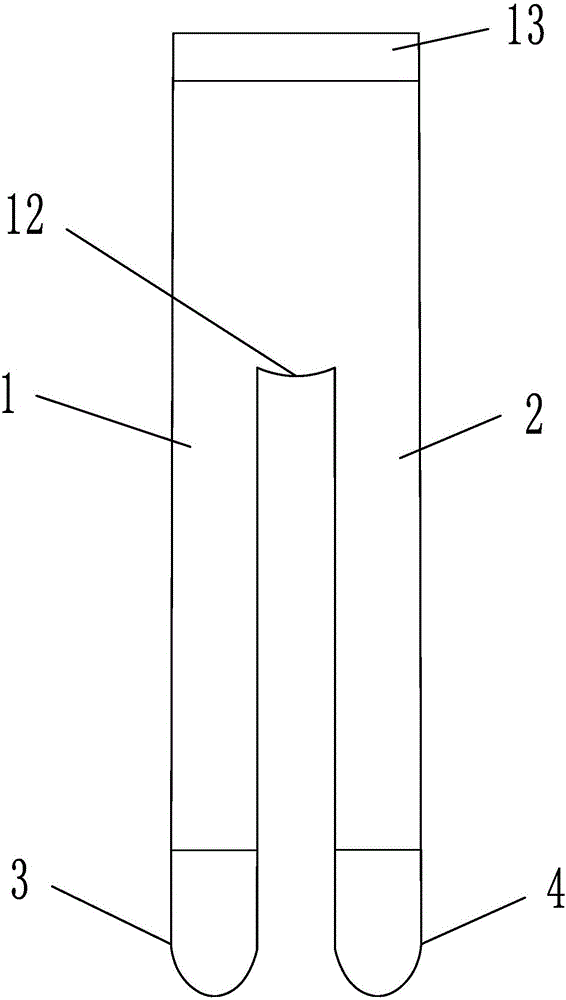

[0016] Embodiment 1: as figure 1 As shown, a kind of seamless stockings includes a trouser body and a sock body, the left trouser leg 1 and the right trouser leg 2 of the trouser body, the sock body includes a left sock 3 and a right sock 4, and the left trouser leg and the right trouser leg are seamless integrally formed structures, The trouser body and the sock body are seamless integrally formed structures, and the trouser body is provided with a crotch portion 12 near the crotch portion, and the crotch portion and the trouser body are integrally formed. The open end of the trouser body is provided with an elastic contraction band 13 .

[0017] A production process of seamless stockings as described above, the steps are as follows: Step 1) According to the overall size design, decompose the pattern, and draw the weft knitting process diagram; Step 2) Add a common constant-speed yarn feeding tensioner to the hosiery machine With an active variable-speed yarn feeding tension...

Embodiment 2

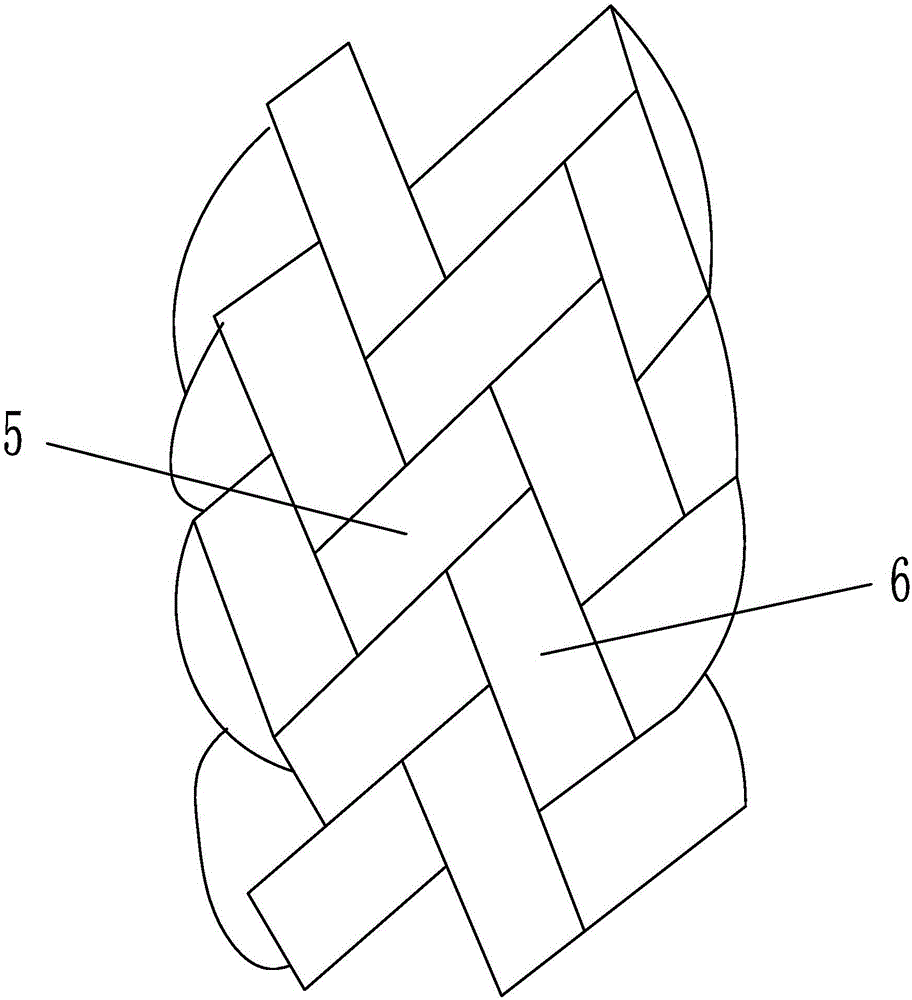

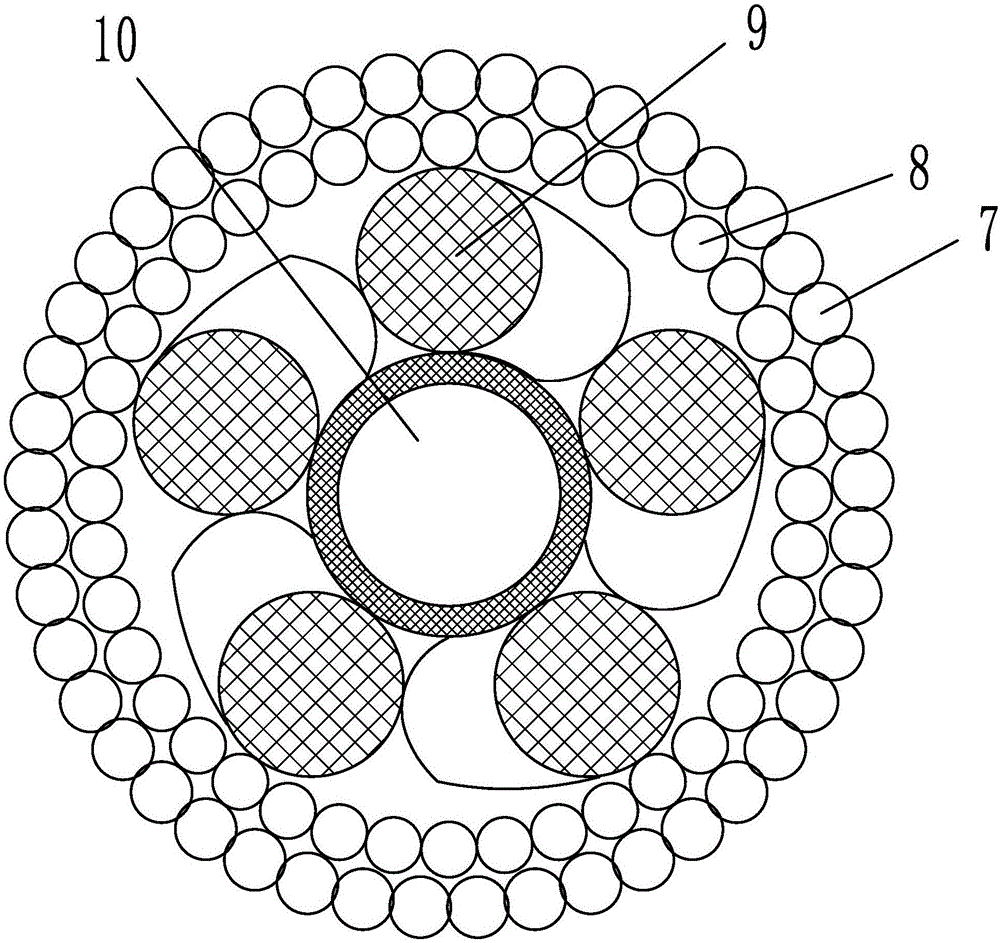

[0019] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 2 , 3 As shown, the trouser body and the sock body are integrally woven with yarn, and the yarn includes an outer layer 7, an inner layer 8 and a base layer, and both the outer layer and the inner layer include several first windings 5 and several second windings Winding 6, the first winding and the second winding are distributed helically around the axis of the yarn, the helical directions of the first winding and the second winding are opposite, the first winding and the second winding overlap each other and form The two second windings are spaced apart, the second winding overlaps the first winding and is separated by the two first windings, the structure of the inner layer and the outer layer is the same, and the base layer includes several yarns distributed around the axis of the yarn. The base line 9 has a curved serpentine tubular st...

Embodiment 3

[0021] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that, as Figure 4 As shown, the yarn twists helically towards the first winding direction, and an arc-shaped hollow part 11 is formed between the second winding and the first winding, and the hollow parts are helically distributed around the yarn axis. The yarn is helically twisted toward the first winding direction, and the first windings are twisted and closely attached to each other in turn, and at the same time, the inner layer and the base layer are pressed, so that the base thread and the positioning sleeve are twisted. When the second winding is also helically twisted towards the first winding direction, the second winding is in a loose state, and as the first winding is tightened, an arc is formed between the loose second winding and the first winding hollow out part. The twisted and tightened first winding is used as the basic support of the yarn, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com