Multidirectional die forging press main cylinder seal ring replacement method

A technology of multi-directional die forging and replacement methods, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve problems such as difficulties, complex equipment, high precision, etc., and achieve fast replacement , the replacement process is simple, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present embodiments do not constitute any limitation to the present invention.

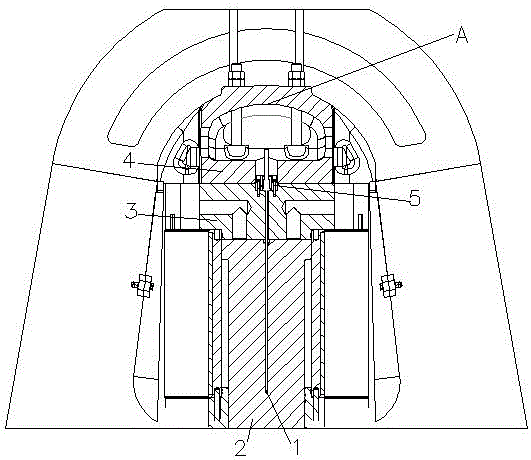

[0024] see figure 1 , a method for replacing the sealing ring of the main cylinder of a multi-directional die forging press, which is carried out according to the following steps:

[0025] (1) After determining the maintenance plan of the press, start to build the disassembly platform. The first floor disassembly platform is located at the height of the lower bottom of the upper semicircular beam 4, and is used to remove the connecting bolts between the upper semicircular beam 4 and the master cylinder and the internal sensor 1 of the master cylinder; Pipes and valves connected to hydraulic cylinders.

[0026] (2) The demolition platform is constructed by directly welding square steel pipes on the press frame, and a steel platform is laid on the platform for walki...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap