Automatic transfer device of hard alloy blades

A technology of cemented carbide blades and transfer device, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of high brittleness of cemented carbide blades, collision of blades with each other, falling edges and corners of blades, etc., to achieve high transport efficiency, The effect of avoiding contact collision and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

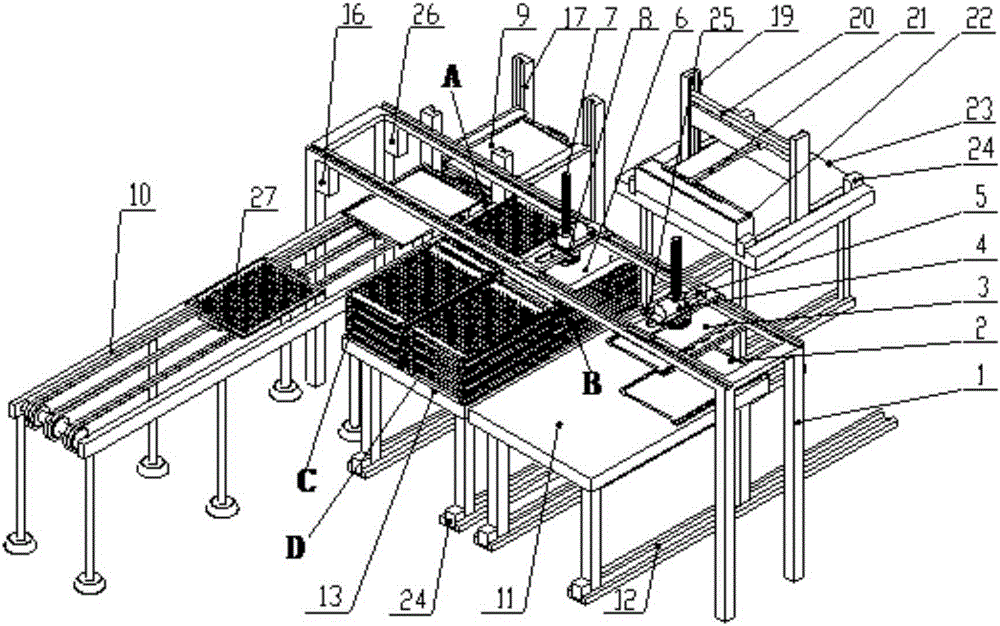

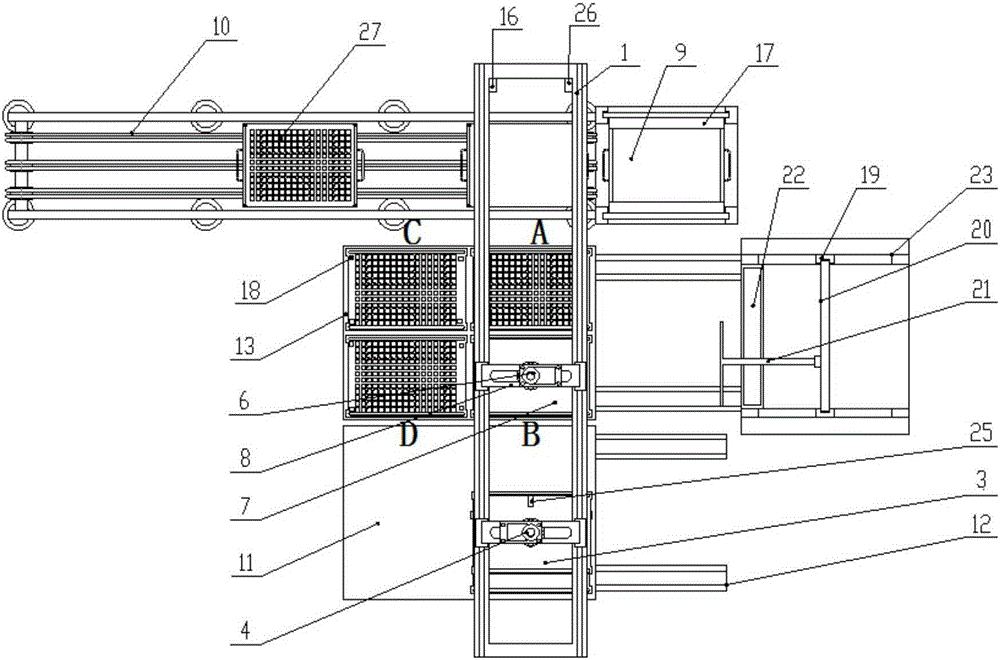

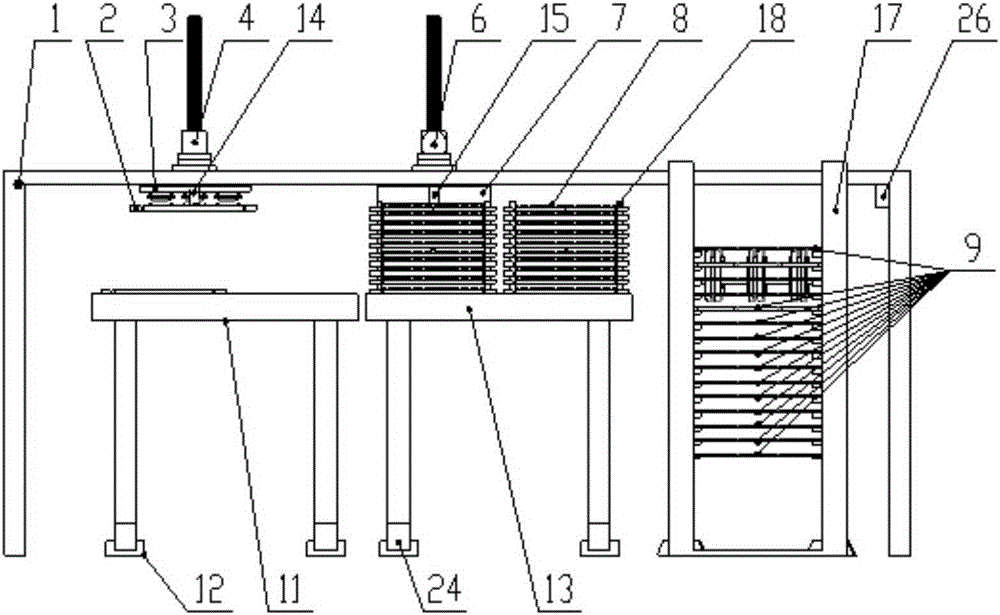

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises guide rail frame 1, boat dish 2, vacuum sucker 3, the second lead screw lifter 4, electromagnetic sucker 6, the first lead screw lifter 7, transmission belt 10, collecting car 11, guide rail 12, stacking car 13 , the second laser range finder 14, the first laser range finder 15, the controller 16, the tray frame 17, the front and rear moving frame 19 of the scraping bar, the up and down moving frame 20 of the scraping bar, the scraping bar 21, the collector 23, Limit block 24, distance sensor 25 and motor 26.

[0020] The first leading screw elevator 7 is installed on the guide rail frame 1 by the first leading screw elevator translation support 8, and can move left and right; the second leading screw elevator 4 is installed on the guide rail frame 1 by the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com