A method and system for increasing the concentration of brine

A brine and concentration technology, applied in the direction of alkali metal chloride, energy input, etc., can solve the problems of high investment, large floor space, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

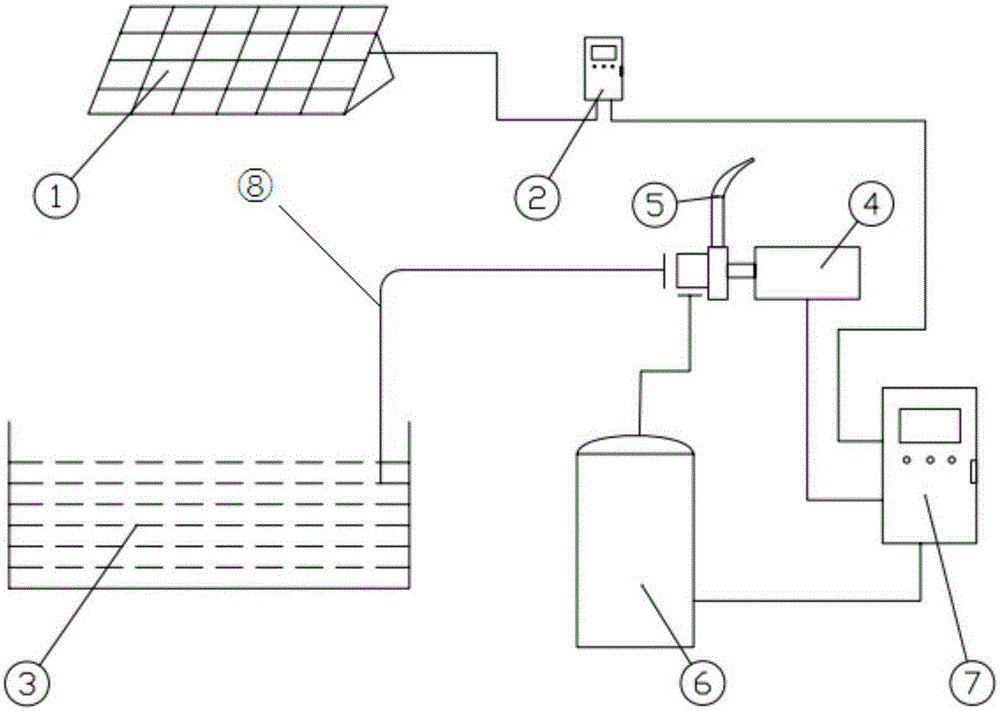

[0048] Such as figure 1 as shown, figure 1 It is a system for increasing the concentration of brine, including: solar photovoltaic power generation equipment 1, photovoltaic controller 2, brine pool 3, fuel photovoltaic water pump 4, injector 5, backwash tank 6, and master control box 7; The photovoltaic controller 2 connected to the outlet of the solar photovoltaic power generation equipment 1, the master control box 7 whose entrance is connected to the outlet of the photovoltaic controller 2; the fuel photovoltaic water pump 5 whose first inlet is connected to the outlet of the master control box 7; The outlet of the fuel photovoltaic water pump 5 is connected to the inlet of the injector 5, and the outlet is connected to the pipeline 8 connected to the second inlet of the fuel photovoltaic water pump 5; the outlet is connected to the brine pool 3 connected to the entrance of the pipeline 8; The outlet is connected to the backwash tank 6, and the outlet is connected to the ...

Embodiment 2

[0050]Concentration in the former brine is 17 degrees Baume, start the equipment of embodiment 1, and set the parameter in the master control box to be: under 40 degree of elevation angles, when the high-speed water pump was set at 2900 revolutions, the pressure was 6 kilograms, and the injection height It is 18 meters, and the spraying distance is 40-50 meters. After the original brine is sprayed by the injector, the concentration of the brine that falls is 19 degrees Baume, and the injection time is completed within 10 seconds from the original brine to the spray landing.

Embodiment 3

[0052] The concentration in the original brine is 23 Baume degrees, start the equipment of embodiment 1, and set the parameter in the master control box as: the rotating speed of the high-speed water pump drops to 2200, and the pressure is 6 kilograms, and the spraying height is 18 meters, and the spraying height is 18 meters. The distance is 30-40 meters. The concentration of the brine that falls after the raw brine is sprayed by the injector rises from 23 degrees Baume to 24 degrees Baume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com