Morphine derivative crystal form I and preparation method and application thereof

A technology of derivatives and crystal forms, applied in the field of crystal form I of morphine derivatives and its preparation, can solve problems such as unstable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

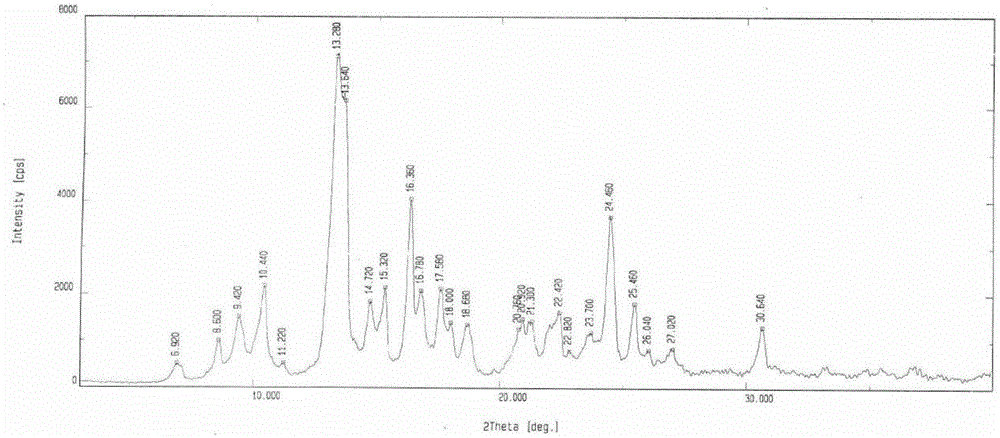

[0092] Dissolve 1g of the morphine derivative shown in Formula 1 (prepared according to the method described in CN201410116005.0) in 5ml of water and 1ml of n-propanol solution, heat at 40°C, add 0.05g of activated carbon for decolorization, and filter to obtain a supersaturated solution. The solution was sealed and placed at -5°C for cooling and crystallization for 24 hours to obtain colorless columnar crystals, which were dried under reduced pressure at 60°C. The diffraction angles 2θ° of the obtained morphine derivatives are at 6.92, 8.60, 9.42, 10.44, 11.22, 13.28, 13.64, 14.72, 15.32, 16.36, 16.78, 17.58, 18.00, 18.68, 20.76, 20.92, 21.30, 22.42, 22.82, 23. There are absorption peaks at 24.46, 25.46, 26.04, 27.02, and 30.64, which is crystal form I. Its X powder diffraction pattern is as figure 1 shown.

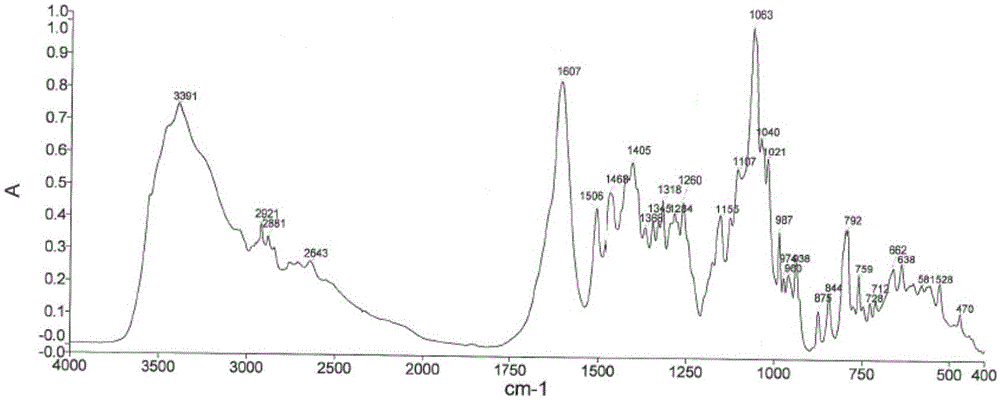

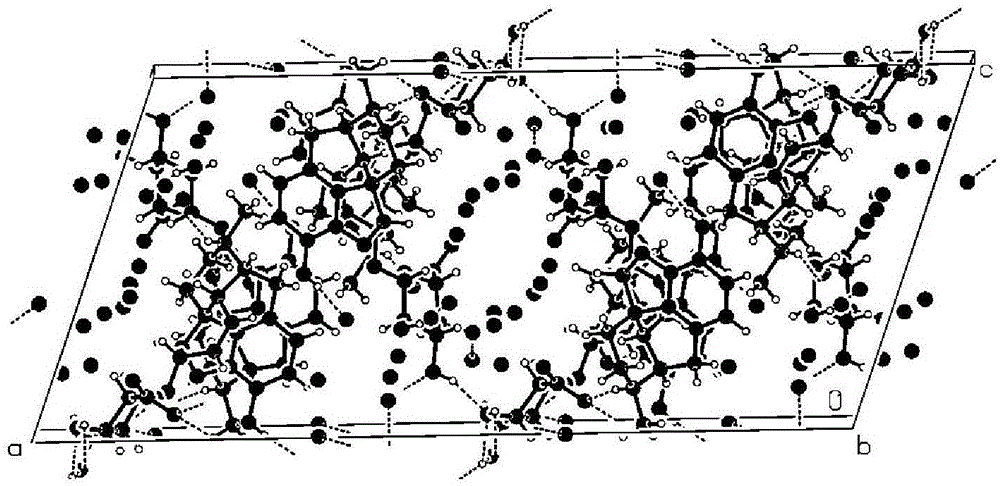

[0093] The crystal parameters of the crystal form I of the morphine derivative shown in the crystal form 1 prepared in Example 1 were determined.

[0094] The single...

Embodiment 2

[0105]Dissolve 1 g of the morphine derivative shown in formula 1 in 3 ml of water and 1 ml of methanol solution, heat at 60 ° C, add 0.1 g of activated carbon for decolorization, filter to obtain a supersaturated solution, seal the solution and place it at 0 ° C for cooling and crystallization for 36 Hours, a colorless columnar crystal was obtained, which was dried under reduced pressure at 50°C. The obtained morphine derivative was identified by the characterization method in Example 1, and it was crystal form I.

Embodiment 3

[0107] Heat 1g of the morphine derivative shown in Formula 1 in 1ml of water and 4ml of ethanol solution at 50°C, add 0.05g of activated carbon for decolorization, and filter to obtain a supersaturated solution. Seal the solution and place it at -10°C for cooling and crystallization for 36 Hours, a colorless columnar crystal was obtained, which was dried under reduced pressure at 40°C and was crystal form I. The obtained morphine derivative was identified by the characterization method in Example 1, and it was crystal form I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com