Cu-containing microalloy high-strength and high-ductility steel and production method thereof

A high-toughness steel and high-strength technology, applied in the field of micro-alloyed steel preparation, can solve the problems of large fluctuations in low-temperature impact properties, increased production costs, and increased difficulty in steel surface quality control, and achieves the effect of reducing content requirements and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adopt the process route of EAF-CONVERTER electric converter smelting→LF furnace refining→VD vacuum treatment→CCM continuous casting to produce Cu-containing micro-alloy high-strength and high-toughness steel,

[0025] Smelting finished product composition control: C: 0.13%, Si: 0.36%, Mn: 1.50%, P: ≤0.010%, S: ≤0.010%, Cr: 0.19%, Cu: 0.25%, Ni: 0.12%, V: 0.09 %, Ti: 0.03%, Al: 0.028%, the balance is Fe,

[0026] The electric converter uses molten iron, pig iron and high-quality steel scrap as raw materials. The total charge is controlled at 100.5 tons, the ratio of molten iron is 93%, the amount of pig iron added is 2.5 tons, and the rest is high-quality steel scrap. %, tapping temperature T: 1634°C, tapping volume 85.9 tons, eccentric bottom tapping and steel retention operation, strictly prohibiting tapping and slag; adding appropriate amount of Al blocks and calcium carbide for deoxidation during tapping, adding low carbon after furnace Ferromanganese, ferrosilicon,...

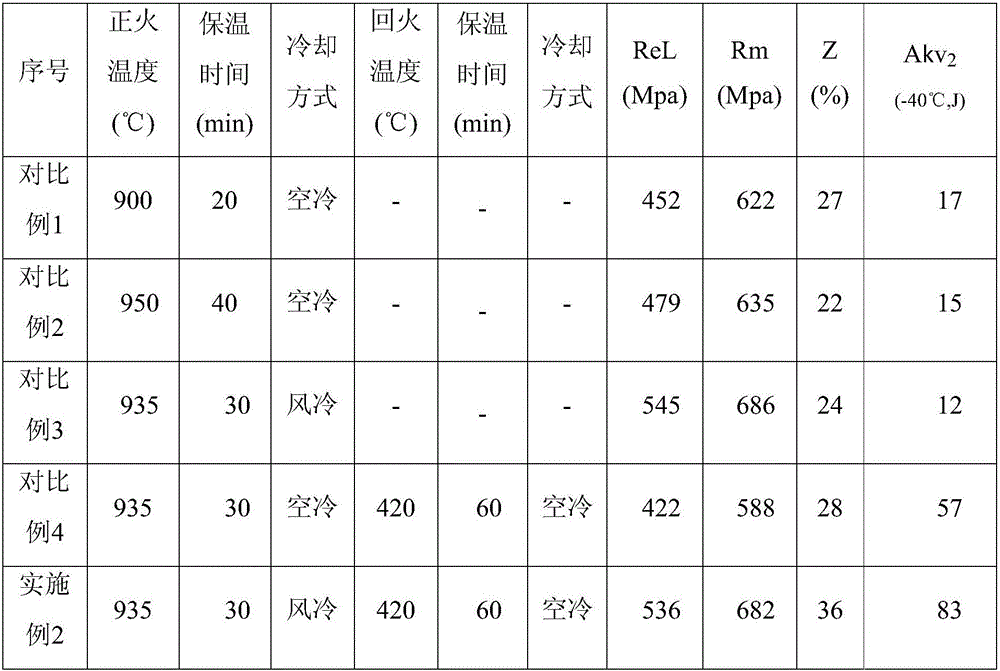

Embodiment 2

[0034]Adopt the process route of EAF-CONVERTER electric converter smelting→LF furnace refining→VD vacuum treatment→CCM continuous casting to produce Cu-containing micro-alloy high-strength and high-toughness steel,

[0035] Smelting finished product composition control: C: 0.14%, Si: 0.40%, Mn: 1.36%, P: ≤0.010%, S: ≤0.010%, Cr: 0.23%, Cu: 0.26%, Ni: 0.12%, V: 0.12 %, Ti: 0.025%, Al: 0.032%, the balance is Fe,

[0036] The electric converter uses molten iron, pig iron and high-quality steel scrap as raw materials. The total charge is controlled at 102.12 tons, the molten iron ratio is 91%, the pig iron addition is 4.3 tons, and the rest is high-quality steel scrap. The composition of the tapping end point is C: 0.04%, P: 0.005 %, tapping temperature T: 1638°C, tapping volume 87.2 tons, eccentric bottom tapping and steel retention operation, strictly prohibiting tapping and slag; adding appropriate amount of Al block and calcium carbide for deoxidation during tapping, adding lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com