A water-cooled layered cooling mold and its application

A mold and layer technology, applied in the field of casting molds, can solve the problems of no cooling scheme, energy waste, high equipment requirements, etc., and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

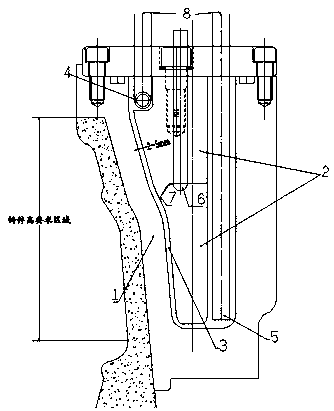

[0016] As shown in the figure, the present invention provides a water-cooled layered cooling mold, which includes a casting mold (1) and a water cavity insert (2), and is characterized in that: the casting mold (1) and the water cavity insert (2) ) to form an accompanying cooling cavity (3), the top of the cooling cavity (3) is embedded with cloth drill holes to form a linear or circular circle of water pipes (4) that evenly enter the water, and the opening is embedded with a sealing ring and locked with a cover plate Tighten to ensure airtightness. The accompanying cooling cavity formed between the mold (1) and the water chamber insert (2) has a gap of 2-5mm. The lower end of the cooling cavity (3) is provided with a water outlet. The water outlets are more than two outlet pipes (5) extending evenly from the bottom of the cavity. The outlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com