Steel backing structure for preventing brake pad from falling off, steel backing manufacturing die and production process

A technology of brake pads and molds, which is applied in the field of brake pads to achieve the effects of performance improvement, safety accident reduction, and high performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a steel back structure is provided to prevent the brake pads from falling off. The size and shape of the present invention are for the convenience of describing the steel back structure, and the present invention is not limited to this embodiment.

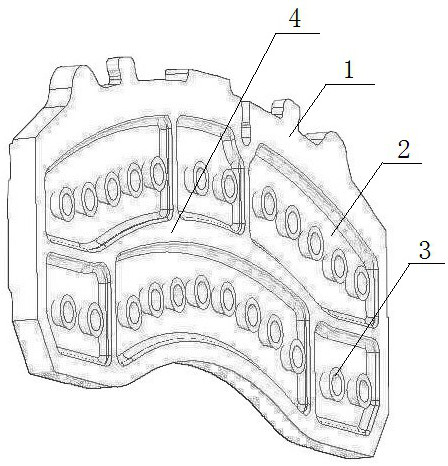

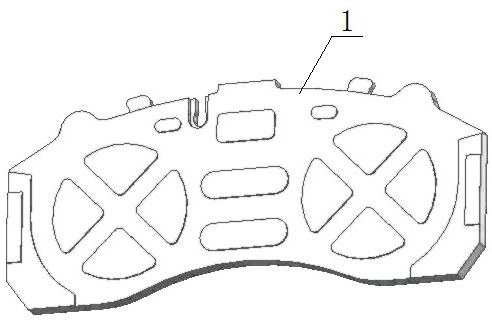

[0038] The structure of the body of the steel back is double-sided, one side is a plane, which is called the front in this application, and the other side is the side where the steel back contacts the friction material, which is called the back in this application. The convex-shaped structure, and the peripheral dimension of the top of the convex-shaped structure is larger than the peripheral dimension of the bottom, the upper surface of the convex-shaped structure is an arc surface concave inward, and the outer contour of the upper surface of the convex-shaped structure is circular, square or polygon, the side can be any shape, but it is necessary to ensure that the raised structure has a large head and a...

Embodiment 2

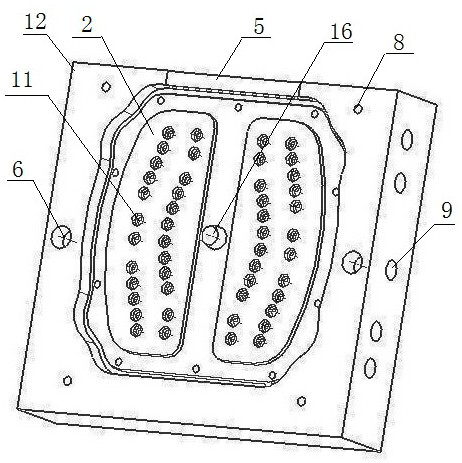

[0041] In this embodiment, the mold is used to make the steel back structure. The mold is divided into two sets, one set is mold one and mold two for producing the friction surface, and the other set is mold three and mold four for producing the back surface. In this embodiment Take the simultaneous production of two steel backs as an introduction.

[0042] Based on the steel back structure of Example 1, mold 1 and mold 2 for producing the friction surface are used together.

[0043] Such as image 3 As shown, there are reverse draft convex nails on the production friction surface. For the convenience of explanation, the orientation terms such as left, right, front, back, and upper surface are used. This application is not limited to this, corresponding to two steel backs and two concave surfaces. The regions are arranged symmetrically on the upper surface of mold one, separated by pouring columns in the middle, and the size, shape, and structure of the two concave regions on...

Embodiment 3

[0052] In this embodiment, the manufacturing process of the steel back structure to prevent the brake pads from falling off, after the mold is developed, it needs to be installed on the core shooter, and then heated to 200-240°C through the heating tube, and the temperature is measured by the thermocouple installed on the mold. The equipment automatically monitors the temperature rise and fall. Afterwards, adjust the sand shooting pressure of the equipment to 3.5-4MPa, and the sand shooting time to 2-4s, and shoot the coated sand into the cavity of the mold through the sand shooting port. Curing 60-90s. Remove the shell and let it cool on a flat plate for 4-5 hours. It is necessary to spray a release agent in the mold cavity every time the shell is made. After production, it is necessary to assemble the core of the inverted tapered convex nail on the back into the sand shell of the front structure. Then assemble the sand shell to 25-30 layers, clamp and install the sprue cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com