Single-phase fluid tube-plate heat absorber loop

A heat absorber and fluid pipe technology, which is applied in the field of high temperature single-phase fluid tube plate heat absorber circuit, can solve the problems of complicated pipeline layout, freezing blockage of molten salt, large number of valves, etc., so as to simplify the pipeline layout and reduce the number of , the effect of reducing the number of valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

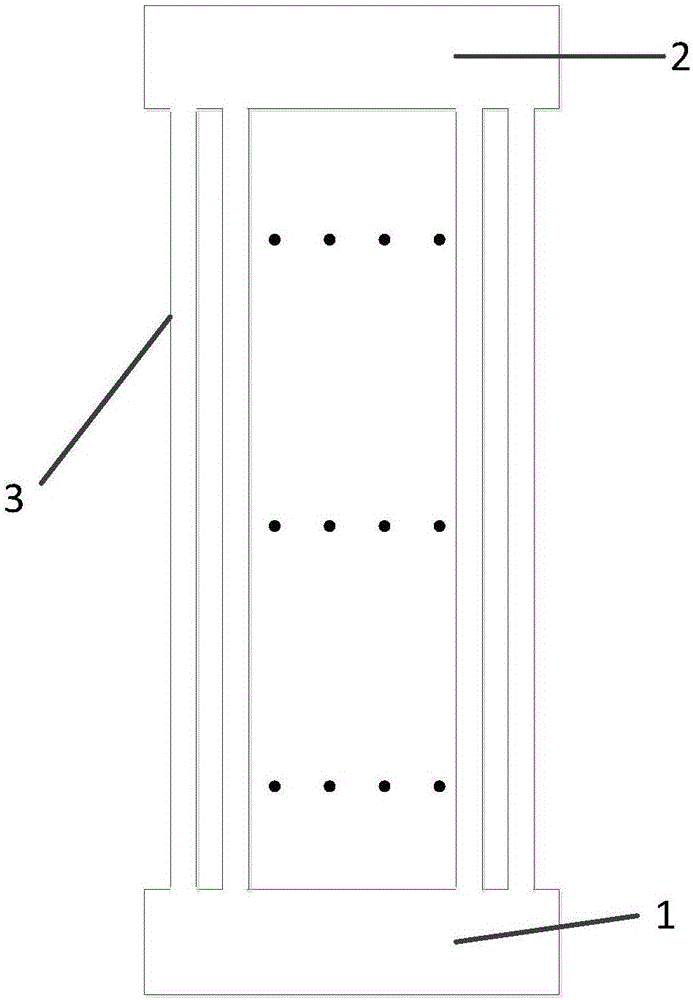

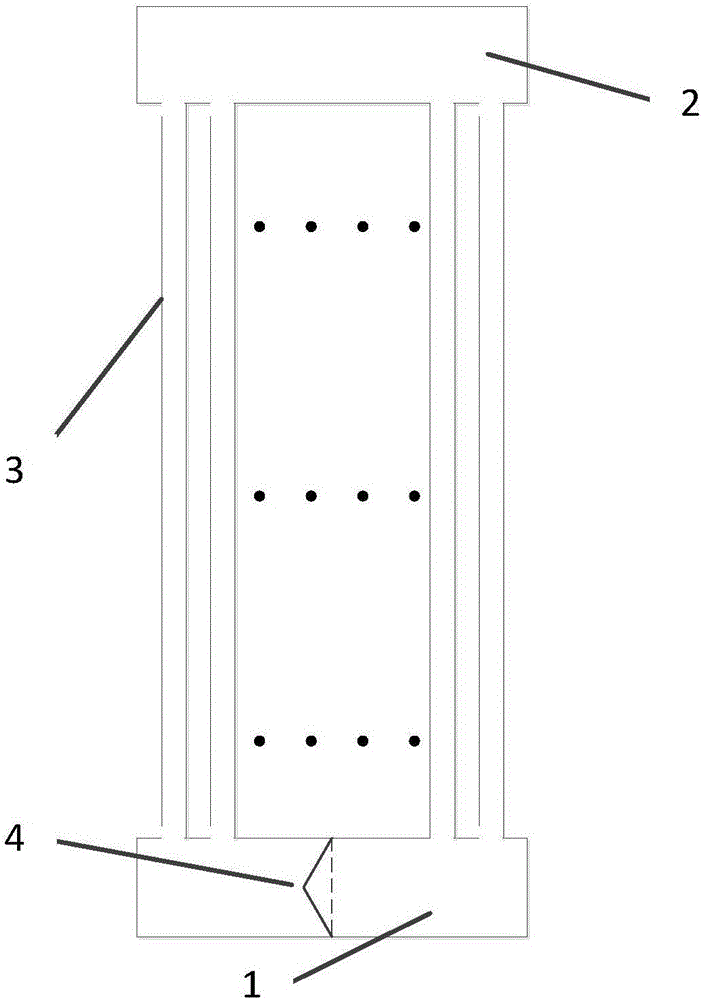

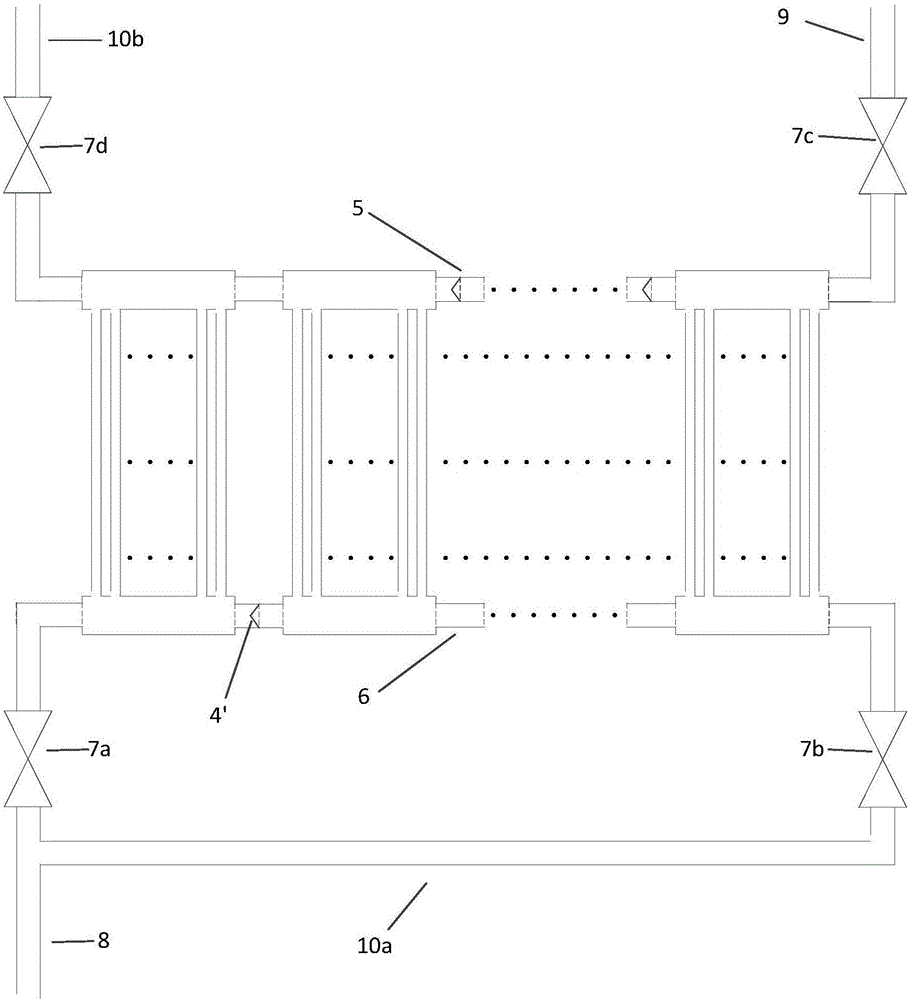

[0021] The circuit of the single-phase fluid tube-sheet heat absorber of the present invention includes a tube sheet composed of a lower header 1, an upper header 2, and a heat-absorbing pipe 3, a first check valve 4, and a connecting pipe with a second check valve 4' 5. Ordinary connecting pipes 6, valves 7, inflow main pipeline 8, outflow main pipeline 9 and auxiliary pipeline 10. The connecting pipe 5 with a check valve and the common connecting pipe 6 are used to communicate with adjacent tube sheets, and are installed between the lower headers 1 and the upper headers 2 of the adjacent tube sheets. The valve 7 is installed on the main inflow pipeline 8 , the main outflow pipeline 9 and the auxiliary pipeline 10 connected with the heat absorber circuit.

[0022] figure 1 Shown is the tube sheet of the first structural form, which is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com