Brake pad and thickness detection method

A technology for brake pads and thickness values, applied in the field of brake pads and thickness detection, can solve the problems of increasing costs, inability to effectively detect the thickness of brake pads, etc., and achieve the effect of reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

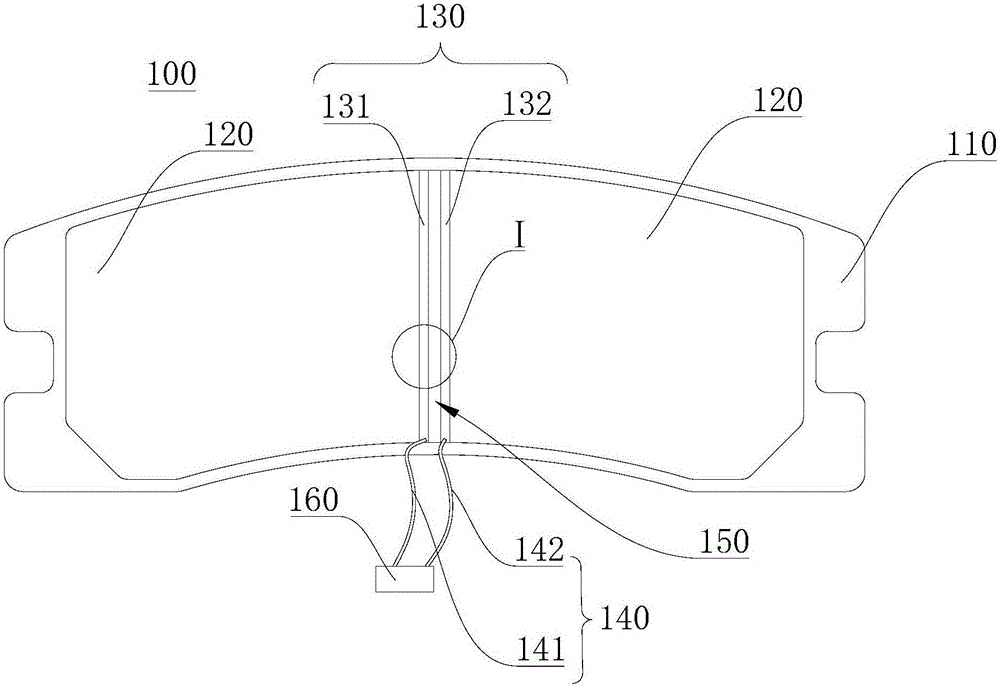

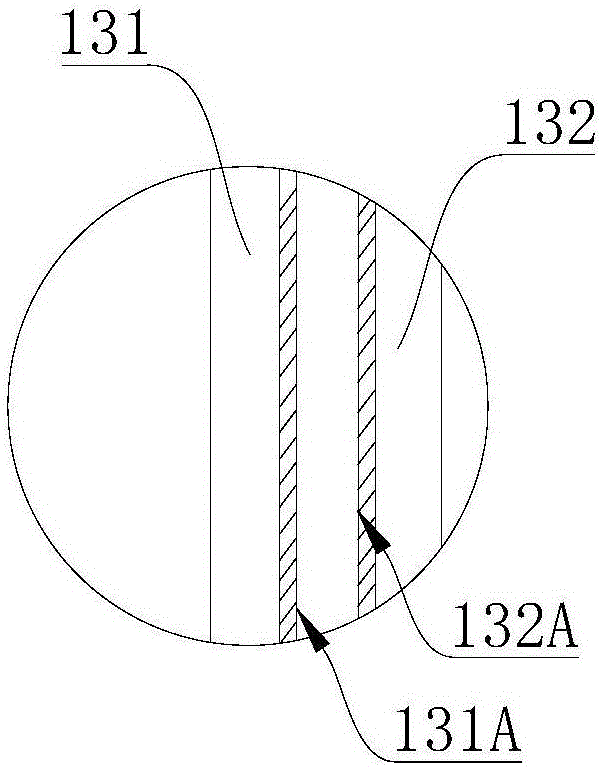

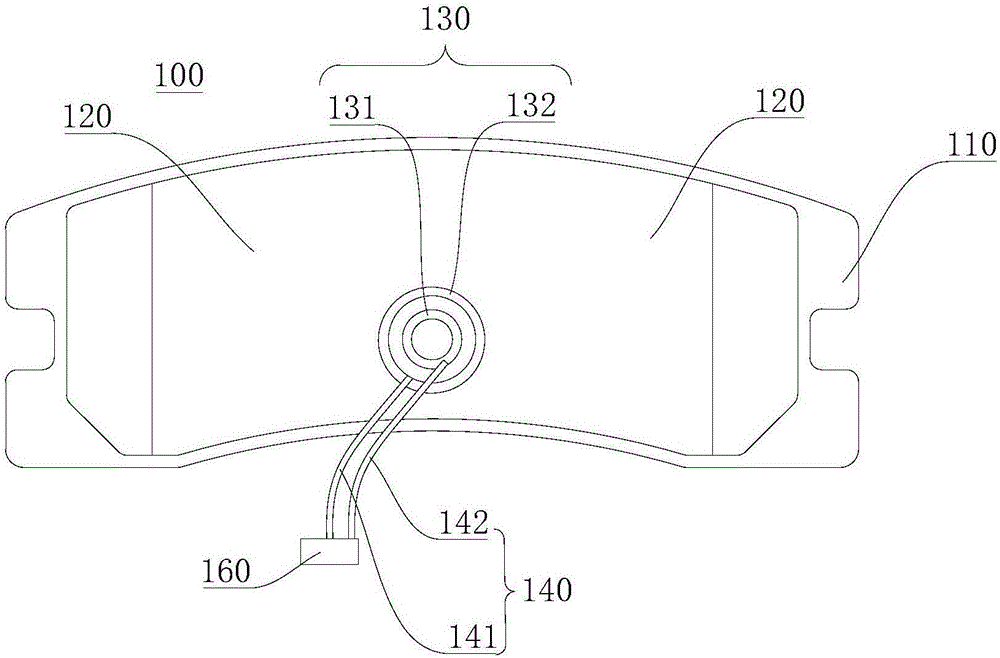

[0022] Please refer to Figure 1 to Figure 3 , the present embodiment provides a brake pad 100 , which includes a back plate 110 , a friction block 120 , a groove 130 , a lead wire 140 , an expansion part 150 , a processor 160 and a heat insulation layer 170 .

[0023] Please refer to figure 1 , in this embodiment, the backplane 110 passes through the heat insulating layer 170 (please refer to image 3 ) is connected with the friction block 120.

[0024] In this embodiment, the back plate 110 is used to connect external devices, for example, to be fixed to a vehicle by means of nuts or welding, and the vehicle may be a car, an electric car, or a motorcycle. The material of the back plate 110 may be stainless steel or titanium alloy, which is not specifically limited in this embodiment.

[0025] In this embodiment, the shape of the back plate 110 may be a rectangle, a circle, or other shapes, which are not specifically limited in this embodiment.

[0026] In this embodiment...

no. 2 example

[0055] see Figure 5 , is a flowchart of a thickness detection method provided by the second embodiment of the present invention. The method is applied to the brake pad described in the first embodiment. The following will be Figure 5 The specific process shown will be described in detail.

[0056] Step S401, acquiring a capacitance value between the first electrode layer and the second electrode layer.

[0057] Wherein, the facing area of the first electrode layer and the second electrode layer is obtained, and the facing area decreases with the friction between the friction block and the brake disc, that is, the first electrode layer and the second electrode layer One end of the second electrode layer is flush with the horizontal plane of the friction block. When the friction block rubs against the brake disc, the first electrode layer and the second electrode layer will also be rubbed, so the first electrode layer The thicknesses of the electrode layer and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com