Automatic electromagnetic ultrasonic flaw detection apparatus

An electromagnetic ultrasonic and flaw detection device technology, which is applied to the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials. scrolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

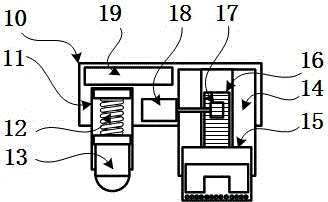

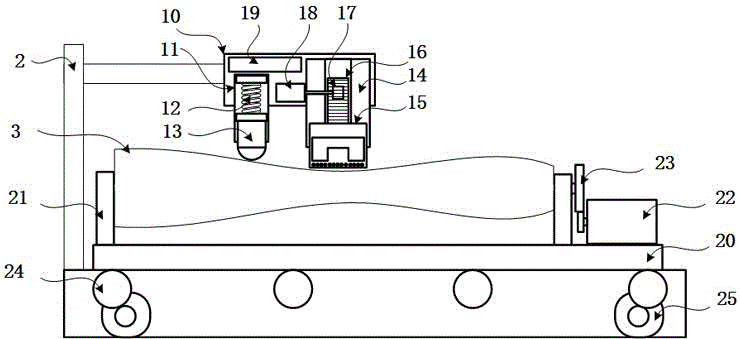

[0016] Such as figure 1 Shown: an electromagnetic ultrasonic automatic flaw detection device, including a probe cover 10, an electromagnetic ultrasonic transducer 15 installed in the probe cover 10 and a detection control circuit system 19, the tail of the electromagnetic ultrasonic transducer 15 is connected to a rack 16, the After the rack 16 is driven by the gear 17 driven by the servo motor 18, the electromagnetic ultrasonic transducer 15 can be controlled to expand and contract in the sensing channel 14 of the probe cover 10; It can sense the distance between the probe cover and the surface of the workpiece to be measured, and the distance signal measured by the sensor is received by the detection control circuit system. In the embodiment, the distance measuring head includes a compression spring 12 installed in the elastic cavity 11, and the contact at the bottom of the compression spring 12 Head 13, and the sliding variable resistor driven by contact head 13. The conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com