Mixed xylene deolefination refining device and method

A technology for removing olefins from xylene and mixing xylenes, applied in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc., can solve the problems of frequent switching of pipelines, affecting product quality, etc. , Extend the service cycle, and improve the effect of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

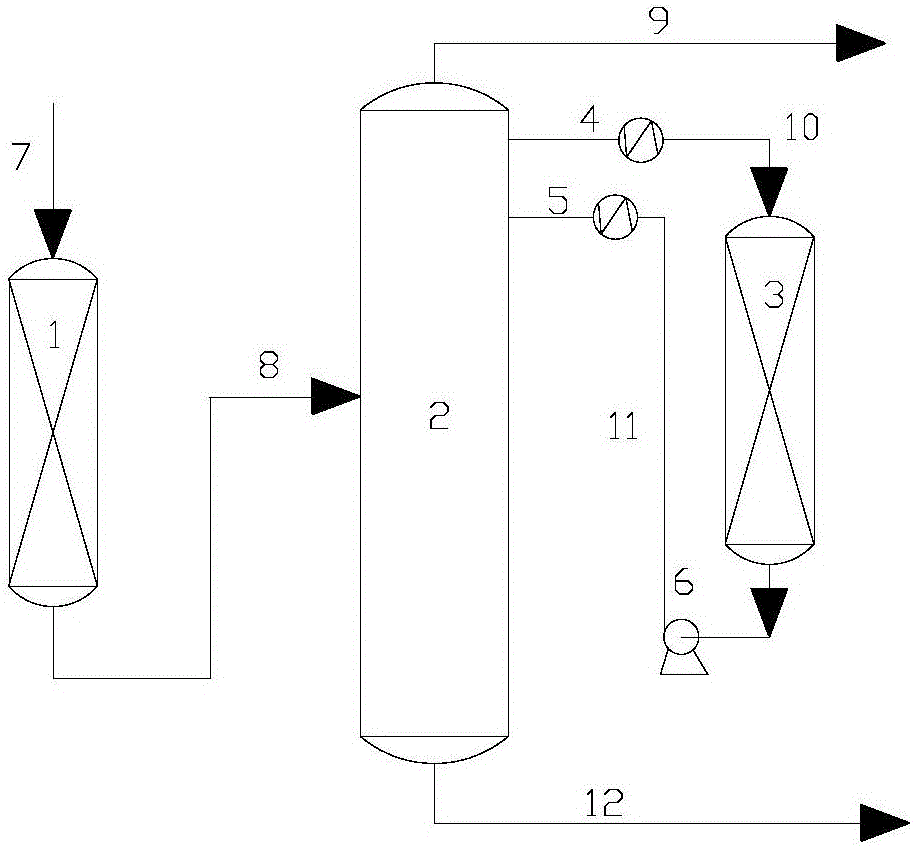

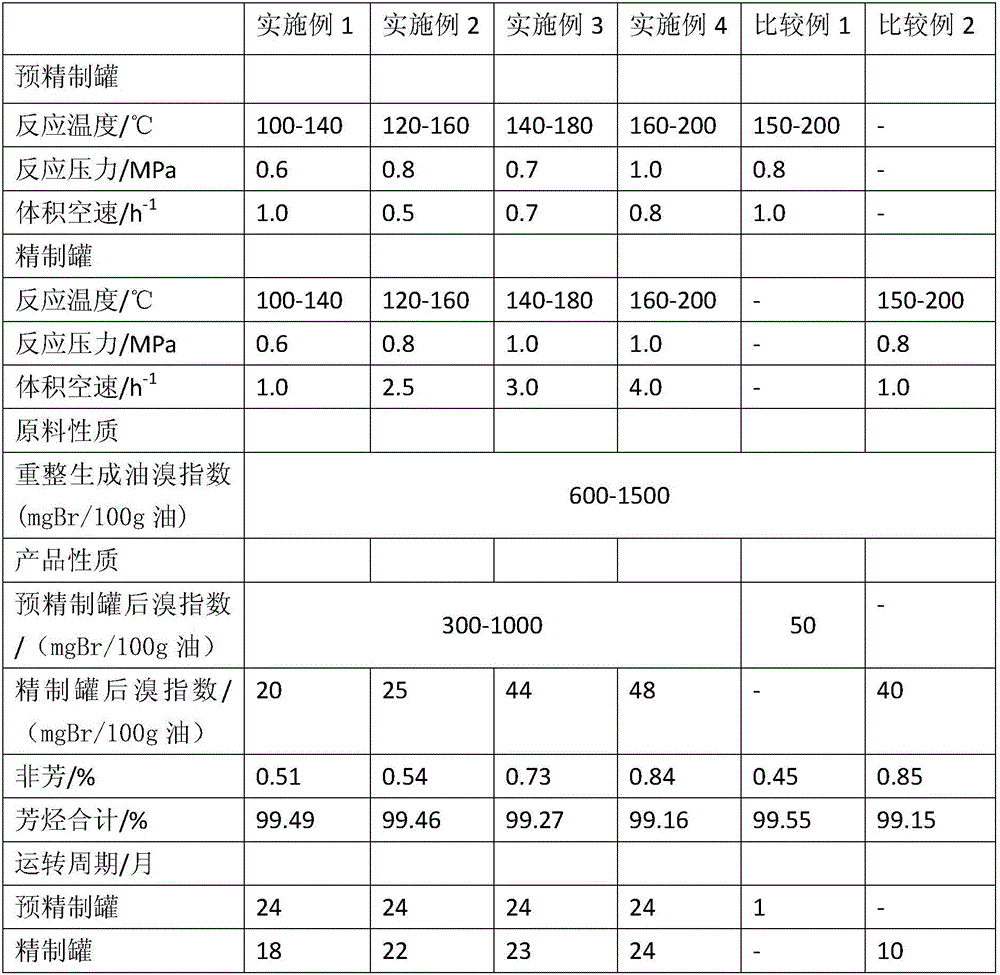

[0024] The reformed oil fraction first enters the pre-refining tank 1, at reaction temperature: 100-140°C, reaction pressure: 0.6MPa, volume space velocity: 1.0h -1 Under certain conditions, after removing part of the olefins, enter the mixed xylene fractionation tower 2 for fractionation, and draw out the mixed C8 cut from the side line above the first tray from the top to the bottom of the mixed xylene fractionation tower 2, and pass through the feed heat exchanger 4 After cooling down, enter the refining tank 3, at reaction temperature: 100-140°C, reaction pressure: 0.6MPa, volumetric space velocity: 1.0h -1 Under the conditions, after removing olefins, return to the mixed xylene fractionation tower 2 on the 6th tray from top to bottom after the centrifugal pump 6 and the discharge heat exchanger 5 heat up, and the top of the tower outputs the mixed xylene product, Polymer with tower kettle C9 + Heavy components are discharged.

Embodiment 2

[0026] The reformed oil fraction first enters the pre-refining tank 1, at reaction temperature: 120-160°C, reaction pressure: 0.8MPa, volume space velocity: 0.5h -1 Under certain conditions, after removing part of the olefins, enter the mixed xylene fractionation tower 2 for fractionation, and draw out the mixed C8 fraction from the top of the fifth tray from the top to bottom of the mixed xylene fractionation tower 2, and pass through the feed heat exchanger 4 After cooling down, enter the refining tank 3, at reaction temperature: 120-160°C, reaction pressure: 0.8MPa, volumetric space velocity: 2.5h -1 Under the conditions, after removing olefins, return to the mixed xylene fractionation tower 2 on the 10th tray from top to bottom after the centrifugal pump 6 and the discharge heat exchanger 5 heat up, and the mixed xylene product is produced at the top of the tower. Polymer with tower kettle C9 + Heavy components are discharged.

Embodiment 3

[0028] The reformed oil fraction first enters the pre-refining tank 1, at the reaction temperature: 140-180°C, reaction pressure: 0.7MPa, volume space velocity: 0.7h -1 Under certain conditions, after removing part of the olefins, enter the mixed xylene fractionation tower 2 for fractionation, from the mixed xylene fractionation tower 2 from the top to the bottom of the second plate, the side line draws out the mixed C8 fraction, and passes through the feed heat exchanger 4 After cooling down, enter the refining tank 3, at reaction temperature: 140-180°C, reaction pressure: 1.0MPa, volumetric space velocity: 3.0h -1 Under the conditions, after removing olefins, return to the mixed xylene fractionation tower 2 on the 7th tray from top to bottom after the centrifugal pump 6 and the discharge heat exchanger 5 heat up, and the top of the tower outputs the mixed xylene product, Polymer with tower kettle C9 + Heavy components are discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com