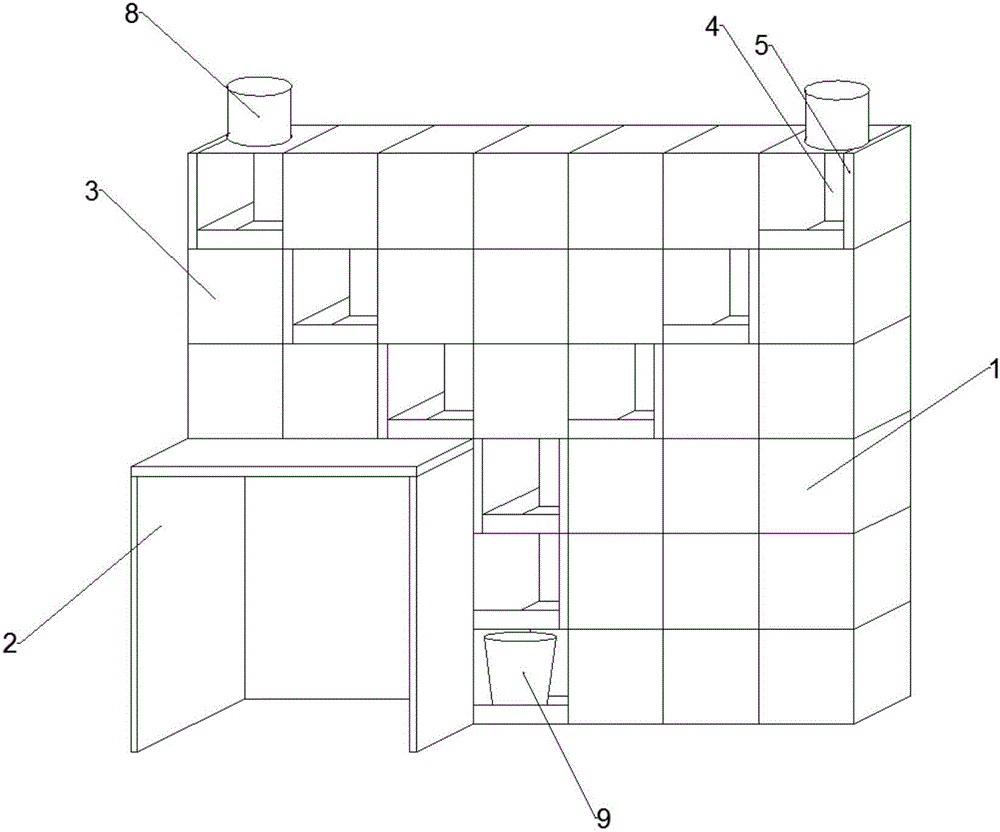

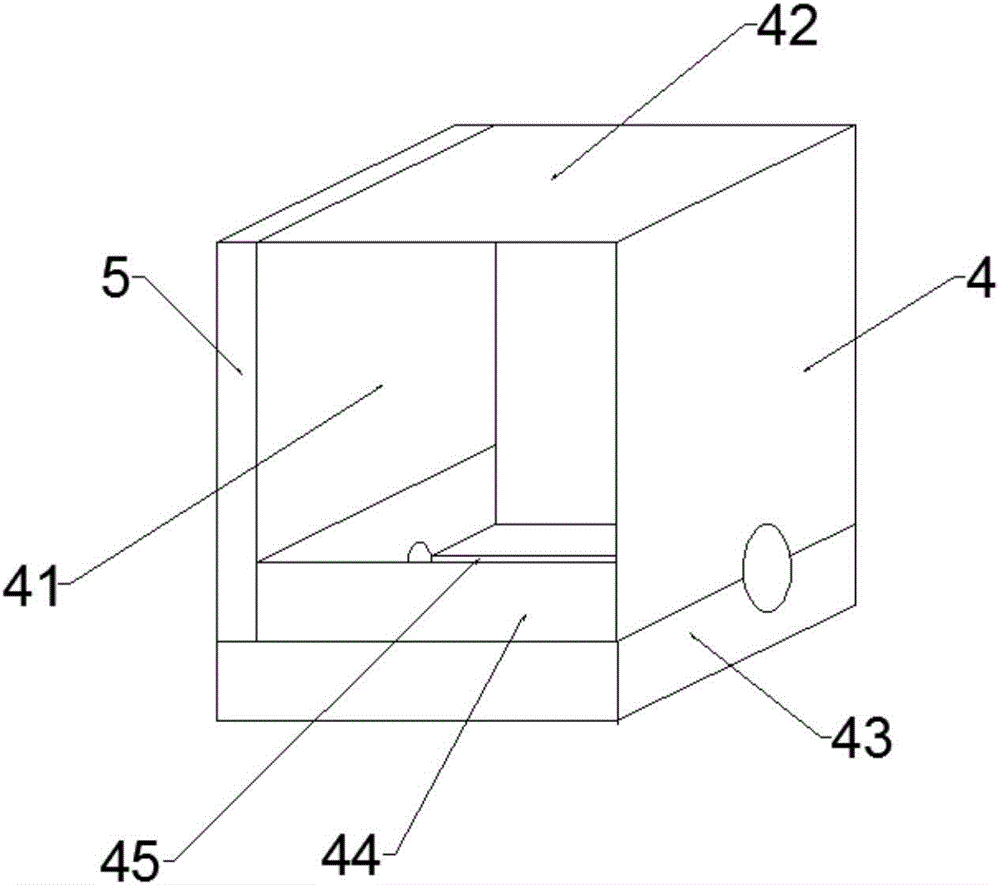

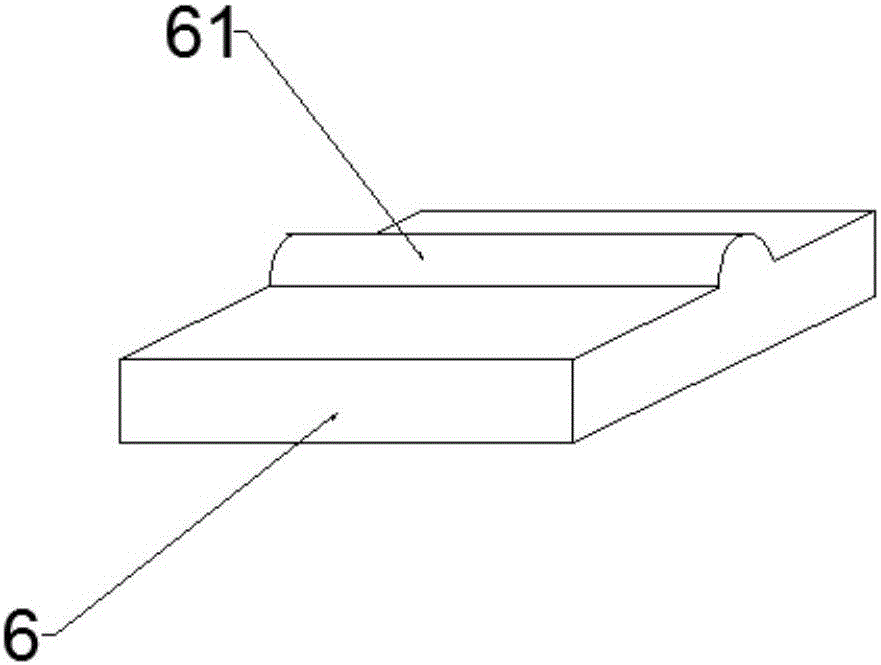

Environment-friendly bookcase

A bookcase and environmental protection technology, applied in the field of household daily necessities, can solve the problem of single function of bookcases, and achieve the effect of beautifying the furniture environment, comfortable office environment, and increasing the decorative function of green plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 100 parts of 20-40% wood chips, 0.1 parts of tea powder, 1 part of polyvinyl formal, 3 parts of urea, 1 part of formaldehyde, 0.5 parts of melamine, 0.5 parts of polyvinyl alcohol, 0.6 parts of water glass, 0.1 parts The elongated foam-like three-dimensional graphene that embodiment 3 makes, 0.01 part of carbon nanofibers are mixed together, obtain base material type mixture; Then water glass is dissolved in the formaldehyde aqueous solution, then polyvinyl formal, urea, melamine , polyvinyl alcohol to mix evenly to obtain a viscous type mixture; mix the viscous type mixture with the substrate type mixture, and dry to a moisture content of about 11%; then pre-press the dried mixture into a billet, and then cold isostatic pressing Process it into slabs; warm and isostatically press the obtained slabs, then cool, temper and sand them to obtain particle boards. Wherein, the hot isothermal pressing temperature is 210° C., and the warm isostatic pressing pressure is 30 MPa. ...

Embodiment 2

[0031] 100 parts of 20-40% wood chips, 0.5 parts of tea powder, 2 parts of polyvinyl formal, 5 parts of urea, 2 parts of formaldehyde, 1.1 parts of melamine, 1.1 parts of polyvinyl alcohol, 1.5 parts of water glass, 0.3 parts The elongated foam-like three-dimensional graphene that embodiment 3 makes, 0.03 part of carbon nanofibers are mixed together, obtain substrate type mixture; Then water glass is dissolved in the formaldehyde aqueous solution, then polyvinyl formal, urea, melamine , polyvinyl alcohol to mix evenly to obtain a viscous type mixture; mix the viscous type mixture with the substrate type mixture, and dry to a moisture content of about 11%; then pre-press the dried mixture into a billet, and then cold isostatic pressing Process it into slabs; warm and isostatically press the obtained slabs, then cool, temper and sand them to obtain particle boards. Wherein, the hot isothermal pressing temperature is 190° C., and the warm isostatic pressing pressure is 35 MPa.

Embodiment 3

[0033] 100 parts of 20-40% wood chips, 1 part of tea powder, 3 parts of polyvinyl formal, 6 parts of urea, 3 parts of formaldehyde, 1.2 parts of melamine, 1.2 parts of polyvinyl alcohol, 1.8 parts of water glass, 0.5 parts The elongated foam-like three-dimensional graphene that embodiment 3 makes, 0.05 part of carbon nanofibers are mixed together, obtain base material type mixture; Then water glass is dissolved in the formaldehyde aqueous solution, then polyvinyl formal, urea, melamine , polyvinyl alcohol to mix evenly to obtain a viscous type mixture; mix the viscous type mixture with the substrate type mixture, and dry to a moisture content of about 11%; then pre-press the dried mixture into a billet, and then cold isostatic pressing Process it into slabs; warm and isostatically press the obtained slabs, then cool, temper and sand them to obtain particle boards. Wherein, the hot isothermal pressing temperature is 210° C., and the warm isostatic pressing pressure is 30 MPa. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com