Support system

A technology of supporting system and supporting steel pipes, applied in the field preparation of pillars and building components, construction, etc., can solve the problems of occupying space, professional construction impact, structural adverse impact, etc., achieve accurate height, reduce rental costs, and adjust height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

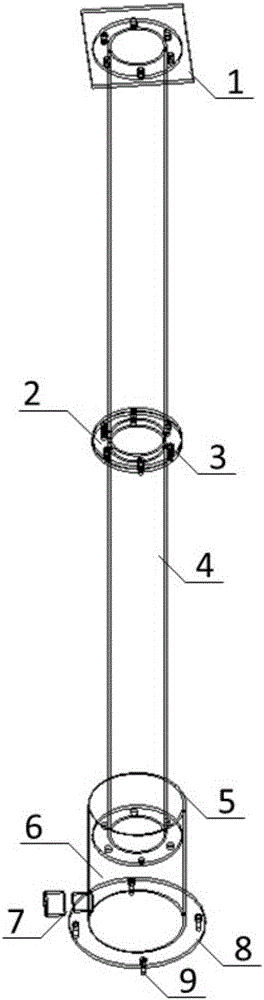

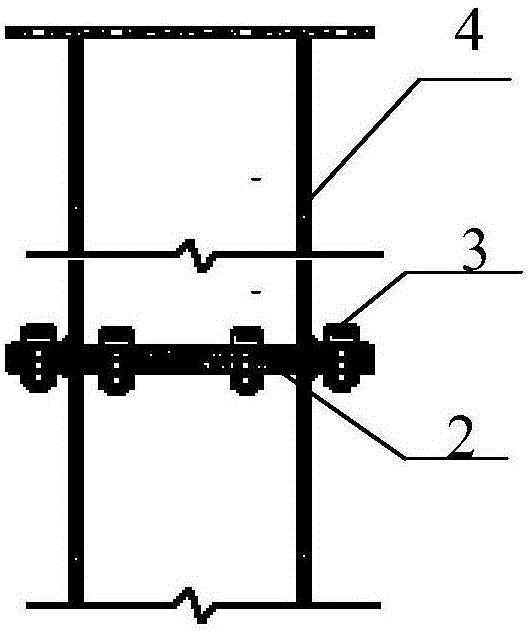

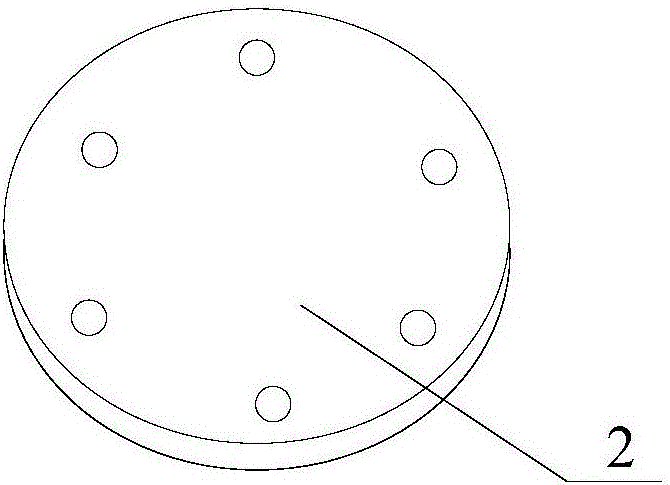

[0030] Please refer to Figure 1 to Figure 6 , the present invention provides a support system, including from bottom to top

[0031] A sandbox 5 is filled with particles, the top is provided with an opening (not shown) for filling particles, and the side is provided with a feed port, and the particles flow out of the sand box 5 from the feed port;

[0032] A pipe extending upwards through the opening from the sand box 5, the end of the pipe in the sand box 5 is provided with a support plate, the support plate surface is placed on the particles and parallel to the horizontal plane.

[0033] The sandbox 5 and the pipeline are combined to form a steel pipe flange member, and the opening of the sandbox 5 is covered with a polyethylene film (not shown) for waterproofing.

[0034] Specifically, the height of the sandbox 5 provided by the present invention is about 0.4m. The pipeline provided by the present invention is formed by connecting several hollow supporting steel pipes 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com