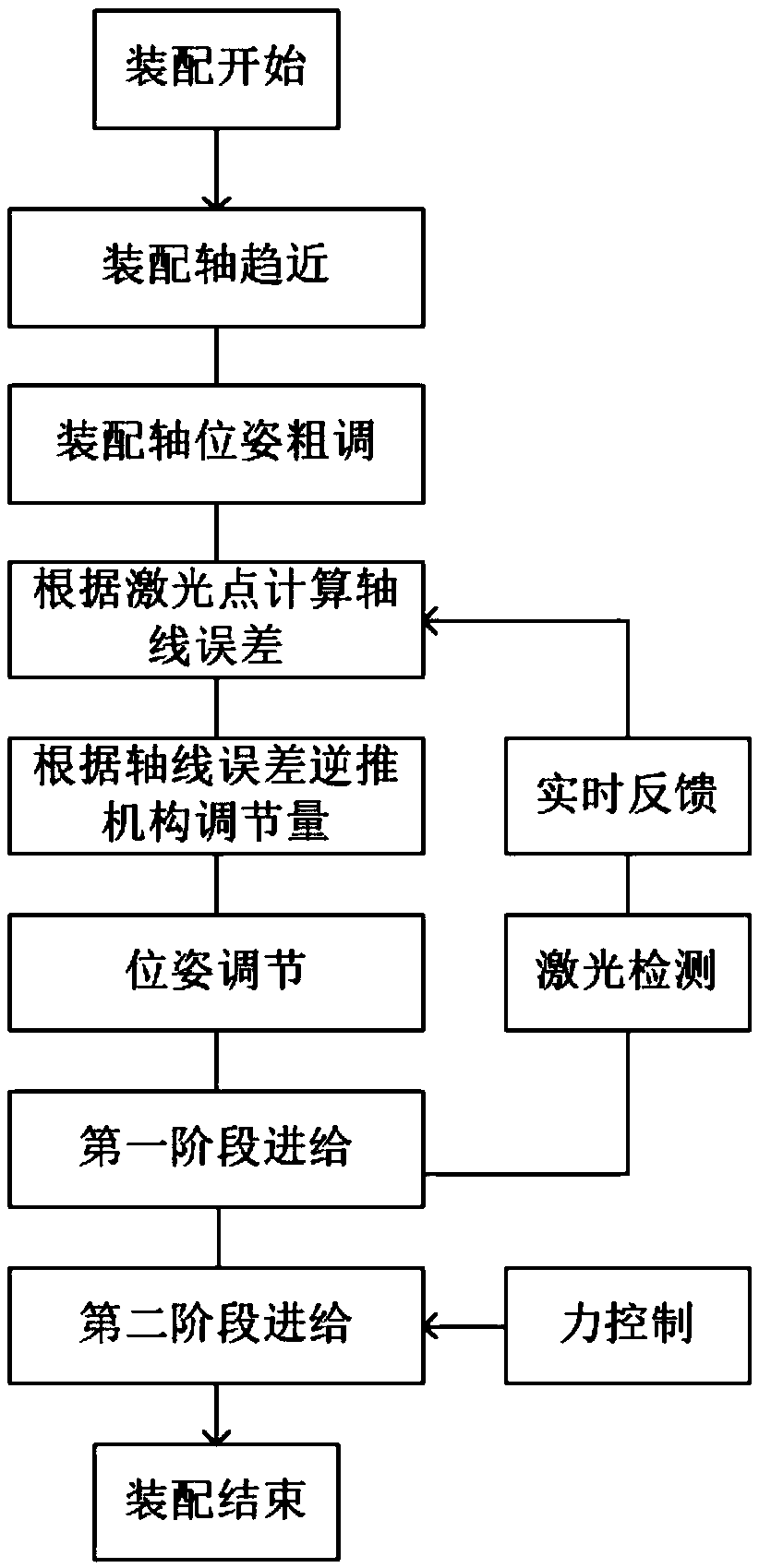

An automatic assembly method for shaft holes based on laser-assisted alignment

An assembly method and laser-assisted technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems that the quality of engine assembly cannot be fully guaranteed, the requirements for workers' technical experience are high, and the workload of assembly workers is heavy. The effect of fast and accurate non-contact detection, improvement of overall efficiency and quality, and improvement of adjustment efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

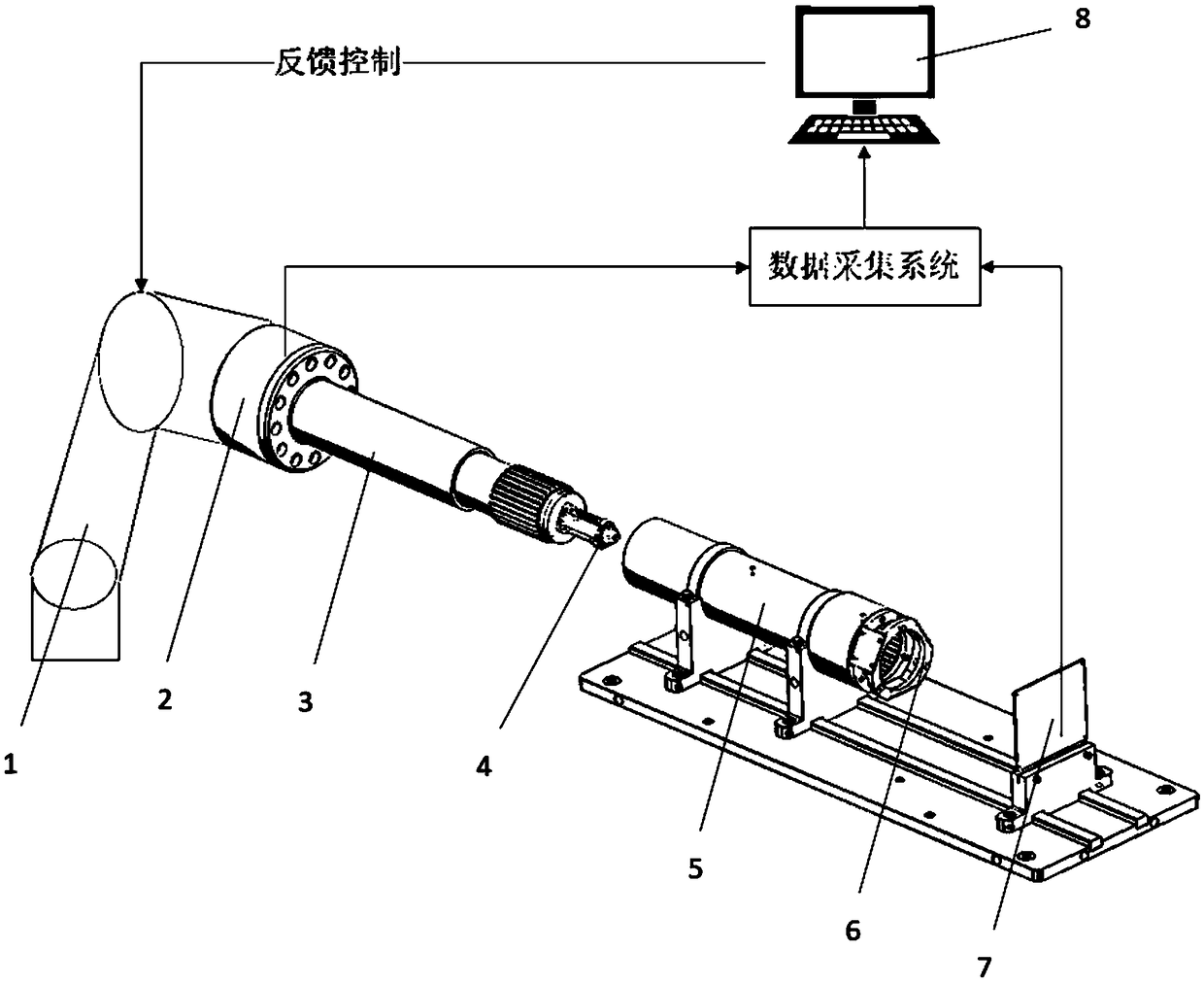

[0043] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention is described in detail below with reference to the accompanying drawings.

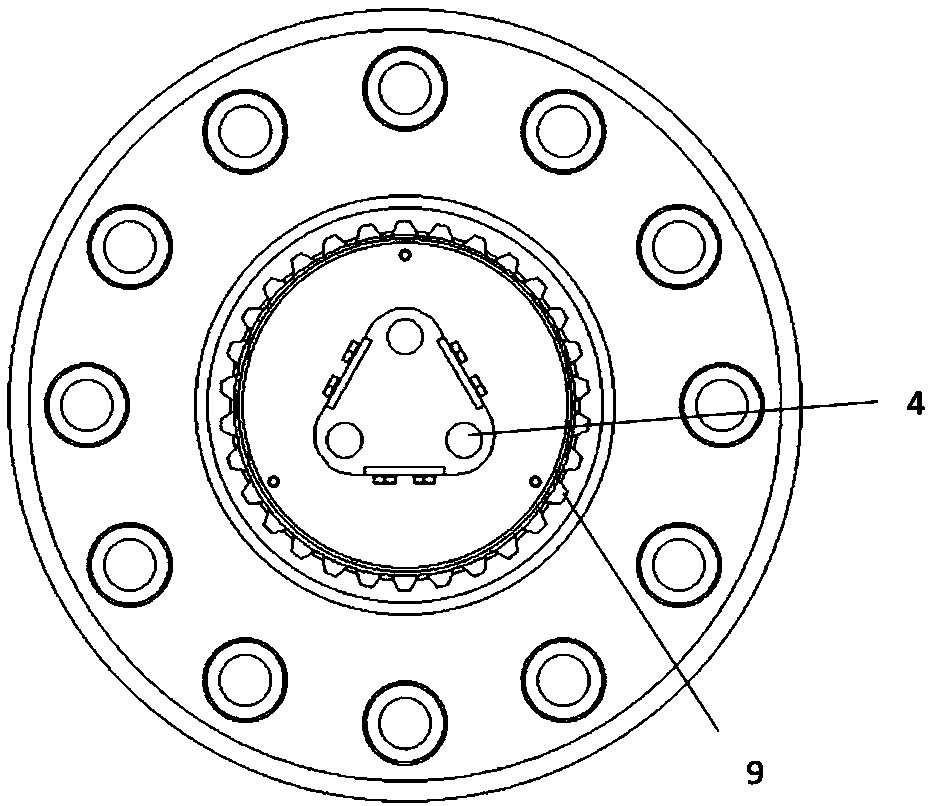

[0044] like figure 2 , 3 As shown in , 4, the shaft end laser generator 4 is installed at the end of the assembly shaft part 3, and has a fixed position angle relationship with the external spline 9 on the assembly shaft part 3; the hole end laser generator 6 is installed at the end of the assembly hole part 5, and The inner splines 10 on the assembly hole part 5 are in a fixed position angle relationship; in this way, when the inner and outer splines can be properly matched, the shaft end laser generator 4 and the hole end laser generator 6 hit the laser point on the PSD position sensor 7 There will be a definite relative position relationship, such as Figure 5 shown.

[0045]If the assembly shaft part 3 is not concentric with the assembly hole part 5, it will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com