High temperature sensitive ceramic armored high-temperature thermocouple and manufacture method thereof

A thermocouple, high-temperature technology, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the problem of service life and performance reduction, platinum-rhodium thermocouples are expensive, Difficult to form and large porosity, etc., to achieve good performance, overcome poor thermal conductivity, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

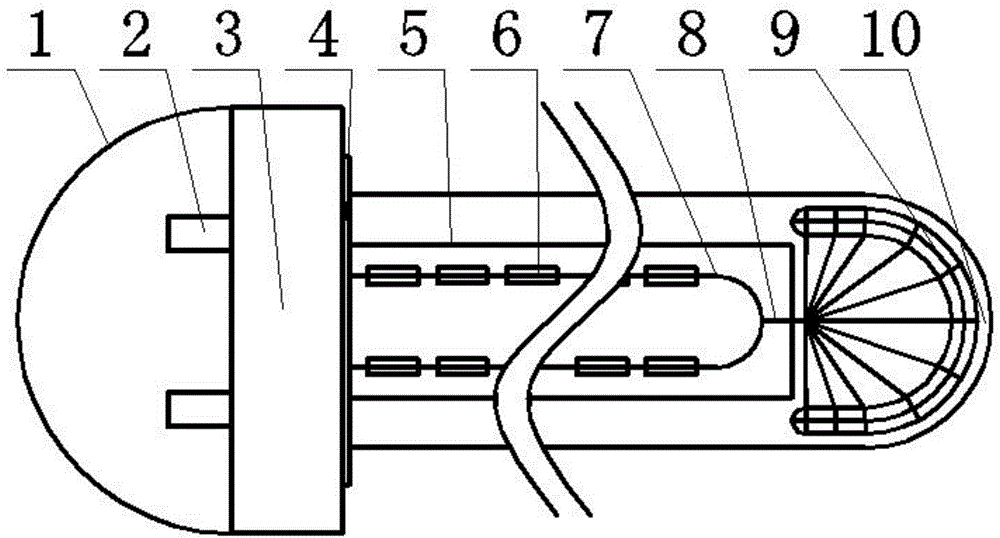

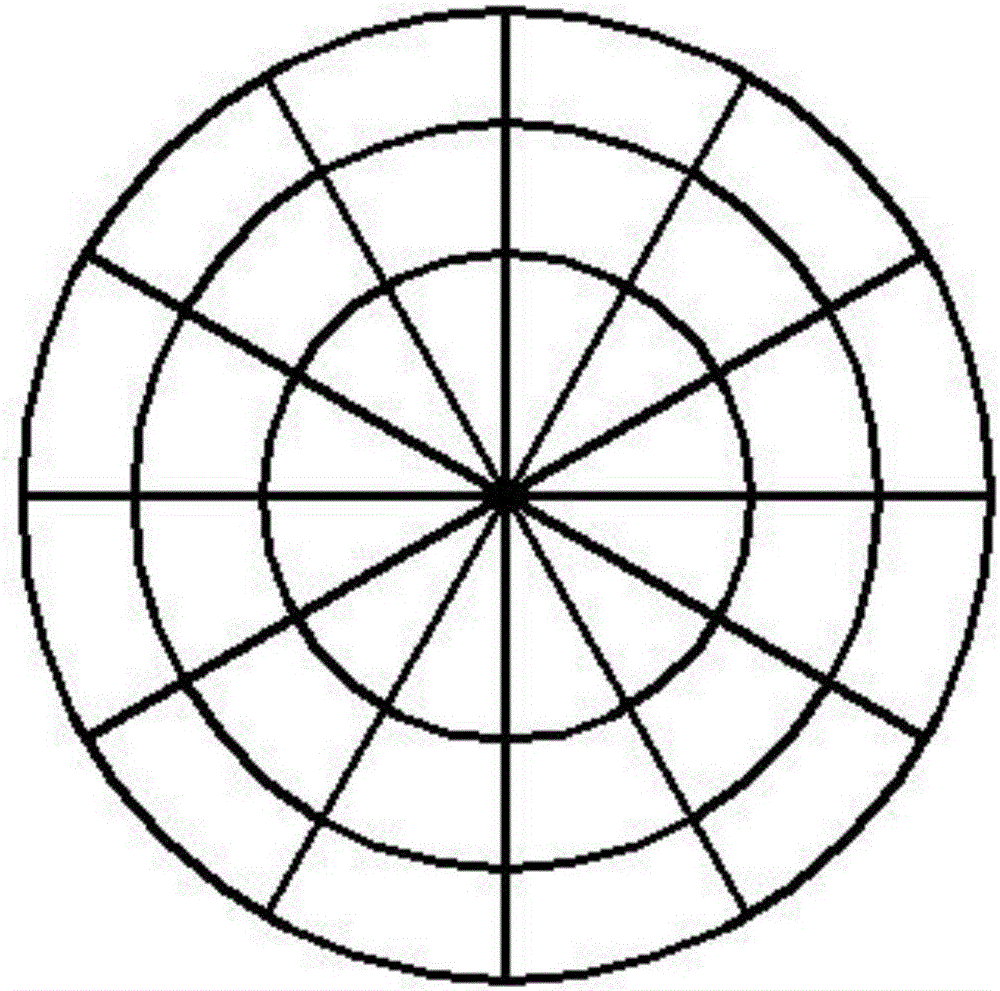

[0023] A high-temperature-sensitive ceramic armored high-temperature thermocouple consists of a junction box 3, a case 1 fixed on the edge of the junction box 3, a terminal post 2 fixed on the junction box 3, a protective sleeve 10, and a protective sleeve 10 The sealing tape 4 between the junction box 3, the insulating layer 5 fixed on the inner surface of the protective sleeve 10, the lead wire 8, the thermocouple wire 7 connected to the lead wire 8 and the terminal 2 respectively, and the thermocouple wire 7 inserted on the Insulator 6, wherein: the protective sleeve 10 is made of alumina-based high-temperature ceramics, the protective sleeve 10 is a hollow structure, the hollow structure is cylindrical, and the ceramic body of the protective sleeve 10 is integrated with a carbon fiber mesh basket 9 The central bundle line of the carbon fiber mesh basket 9 protrudes from the center of the bottom surface of the cylindrical hollow structure to the ceramic body, and the central...

Embodiment 2

[0038] The present embodiment structure and most of method steps are all identical with embodiment 1, difference is as follows:

[0039] 1) Preparation of raw materials, equipment and tooling

[0040] ①Raw materials: prepare a sufficient amount of alumina-based ceramic powder with a mass fraction of 10% aluminate binder, a sufficient amount of carbon fiber, intersperse and fix the insulator 6 according to conventional technology, and connect the positive and negative pole wires through the intermediate connection point NiCrSi-NiSi thermocouple wire 7, junction box 3 with cover 1 and terminal 2 installed, high temperature glue HN-767A;

[0041] ②Equipment and tooling: prepare vacuum ceramic sintering furnace; ceramic sintering mold; vacuum packaging equipment; oven;

[0042] 2) Forming of the temperature measuring end structure including the protective sleeve 10, the carbon fiber basket 9, and the lead wire 8

[0043] ①Put the prepared alumina-based ceramic powder into the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com