Method for evaluating soil stress corrosion cracking of high-strength pipeline

A technology for stress corrosion cracking and evaluation methods, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as large losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

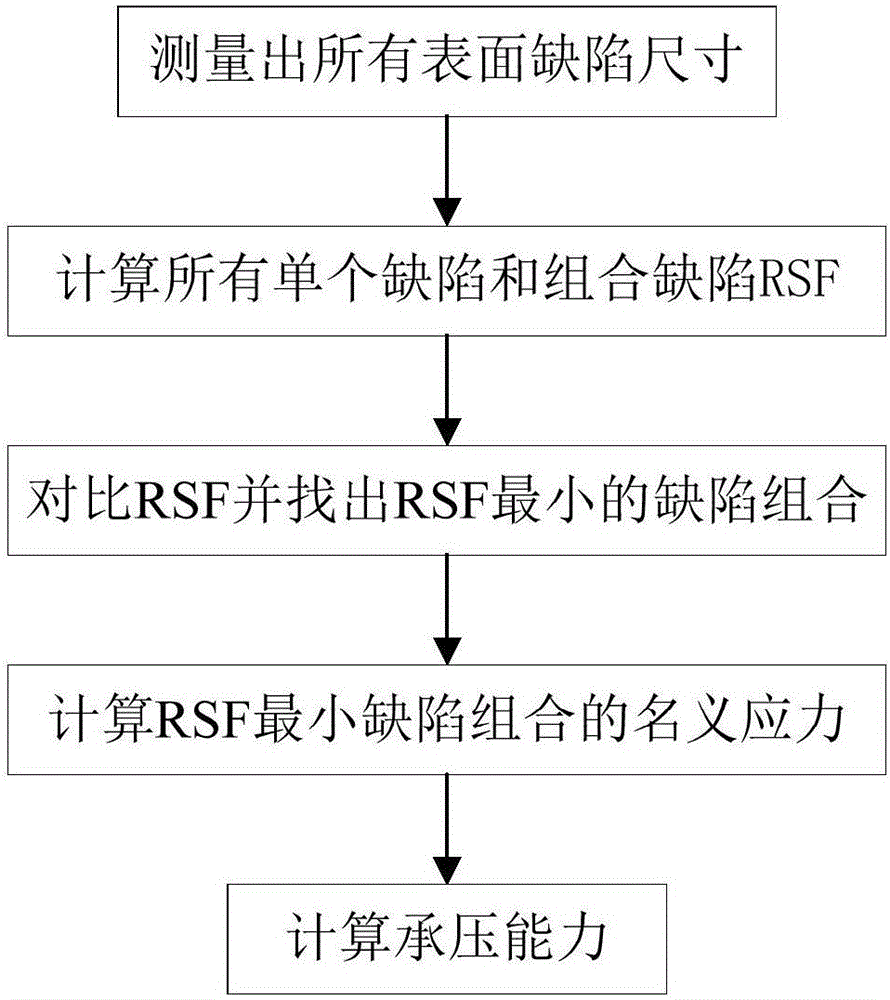

[0025] see figure 1 , the method for evaluating stress corrosion cracking of high-strength pipeline soil of the present invention is characterized in that, comprising the following steps:

[0026] 1) Measure the crack length and wall thickness direction depth of all surface defects, and the combined defects are determined according to the characterization method of crack defects in the standard API579-2007;

[0027] 2) Calculate the RSF values of all individual flaws and combined flaws, where RSF is the residual strength factor;

[0028] Calculate the RSF value of all individual defects and combined defects using the following formula:

[0029] RSF=[(1-A / A o ) / (1-A / (MA o ))] (1)

[0030] Among them, A is the effective defect area; A 0 is the defect length multiplied by the wall thickness; M is the swelling factor.

[0031] 3) Compare the RSF to find the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com