Design method of continuous spiral phase plate

A spiral phase plate and design method technology, applied in the field of optics, can solve the problems of reducing the optical performance of the vortex light field, the influence of optical conversion efficiency, and large processing errors, so as to meet the requirements of optical performance and solve the problems of low output performance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention is further described.

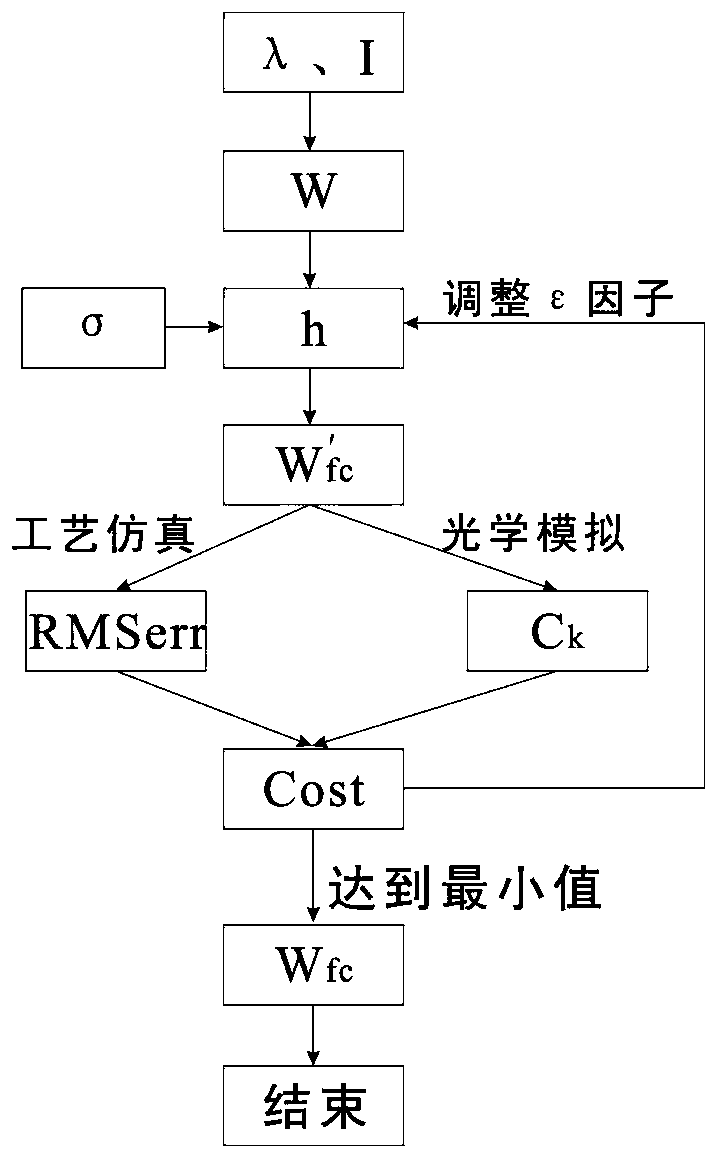

[0037] Continuous spiral phase plate design method, the process is as follows figure 1 as shown,

[0038] Step A: Determine the wavelength of the laser used in the design of the continuous spiral phase plate λ = 800nm, the aperture S = 180mm, and the corresponding light field E of the laser 1 for plane light;

[0039] Step B: The target image distribution I is a hollow annular focal spot, the imaging distance L is the focal length of the focusing lens, L=2000mm, that is, the imaging plane is the focal plane;

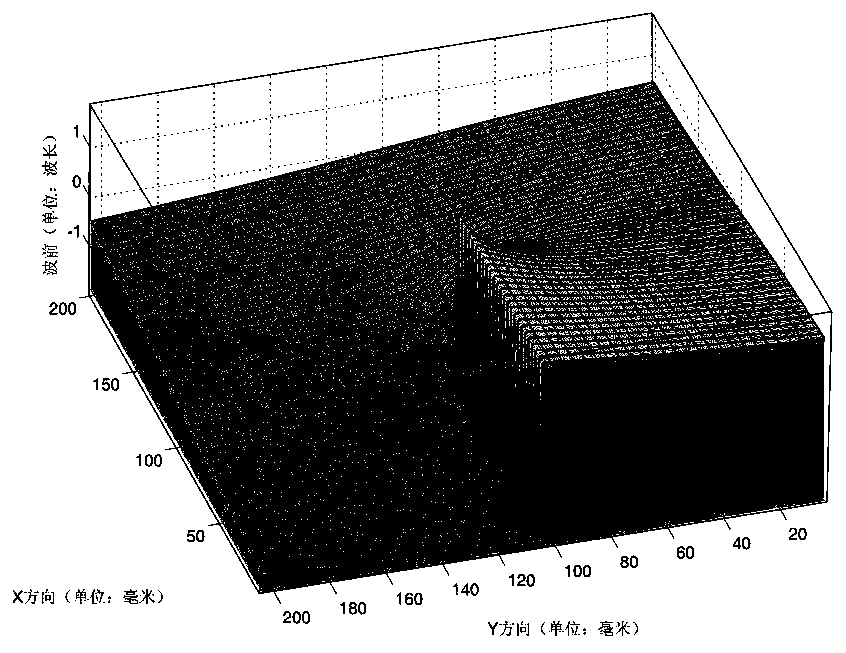

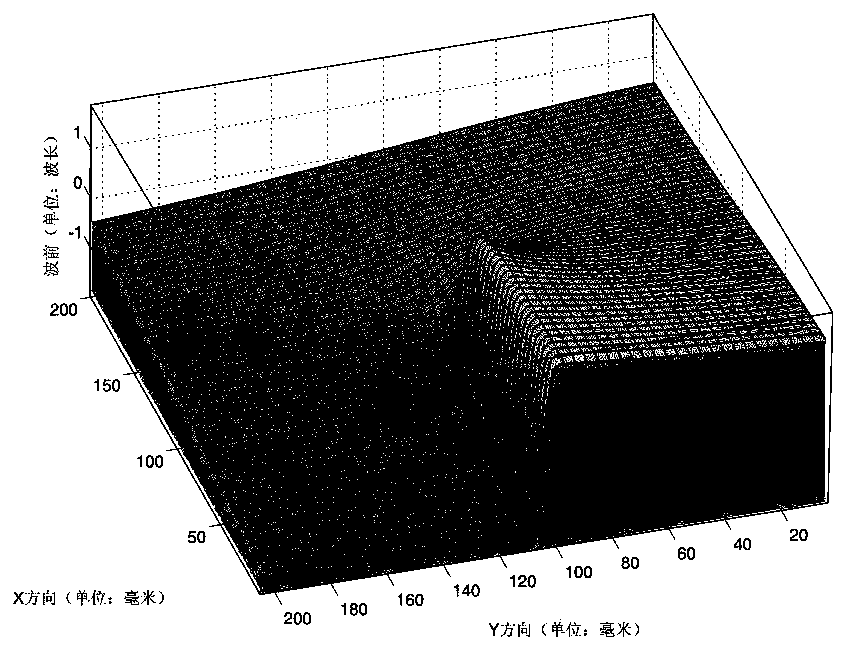

[0040] Step C: Determine the topological charge l=1 and size D=200mm of the ideal spiral phase plate according to the aperture S and the target image distribution I, and its three-dimensional structure is as follows figure 2 As shown, the value range of the wavefront W of the ideal spiral phase plate is (-λ,λ), and the wavefront W consists of two parts: a continuous spiral risin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com