Shutter switcher applied to infrared thermal imager technologies

An infrared thermal imager and switcher technology, applied in the field of infrared thermal imagers, can solve the problems of complex product structure, poor product stability, high and low temperature deformation, etc., and achieve the effect of saving manufacturing molds, saving overall space, and large magnetic field force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

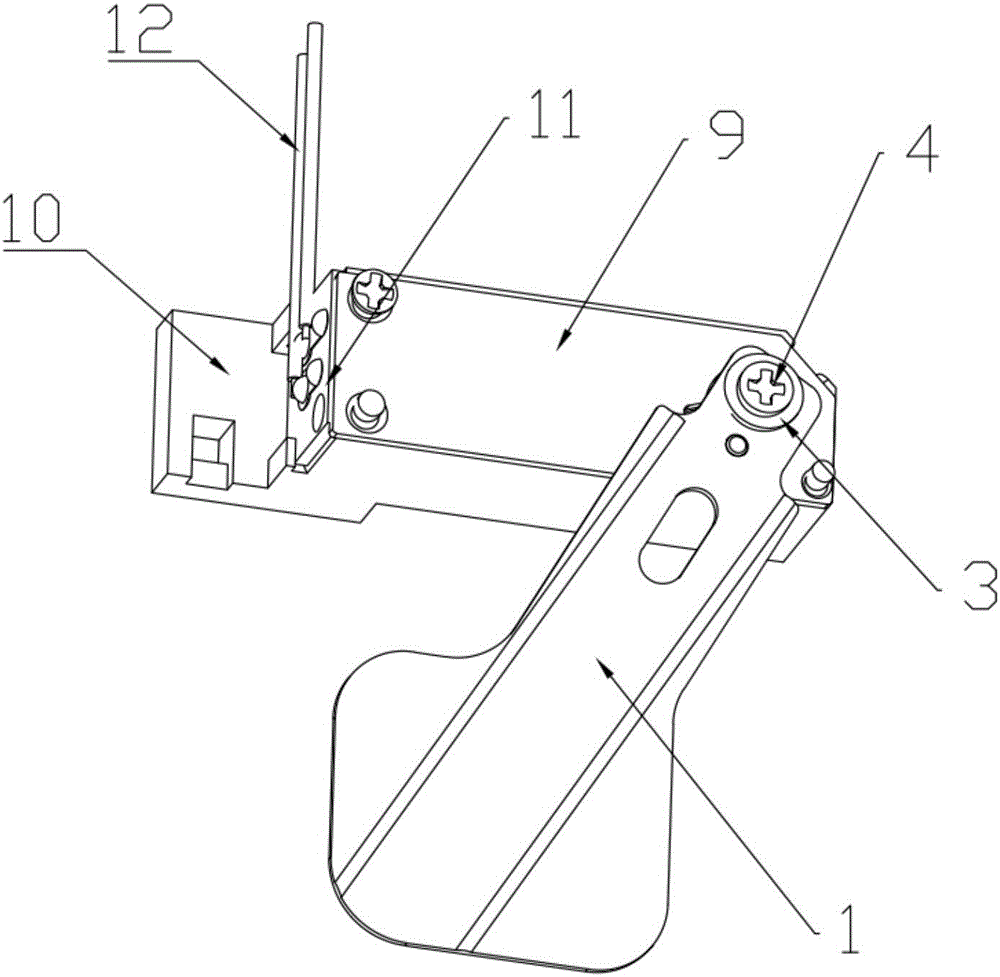

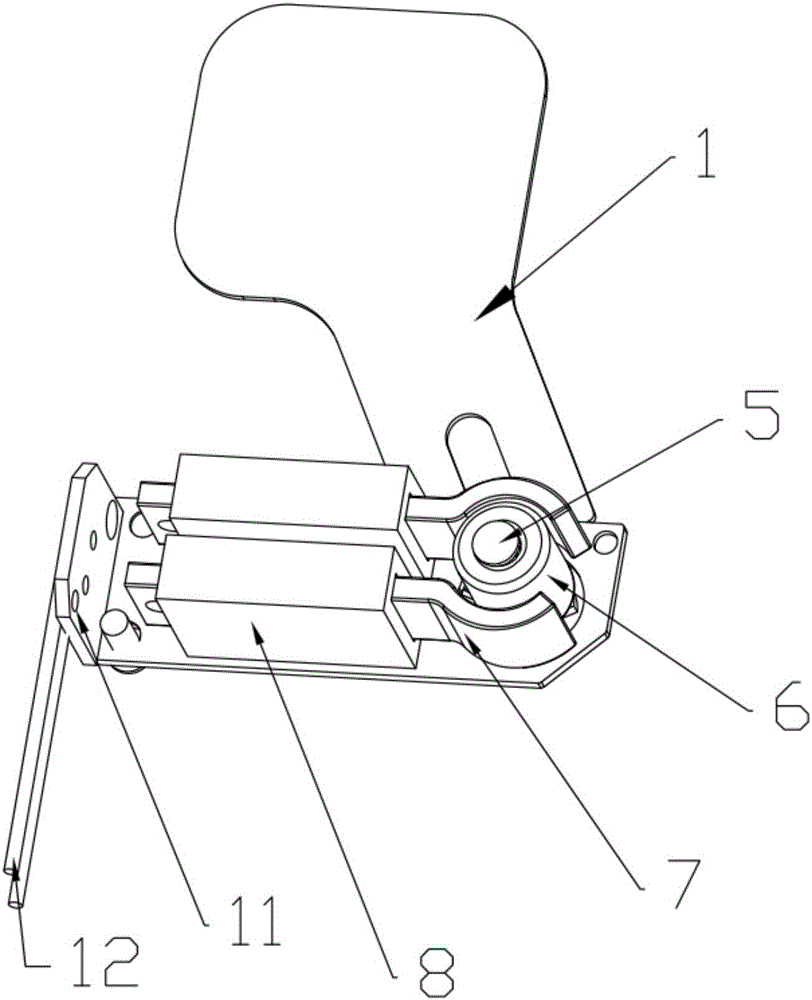

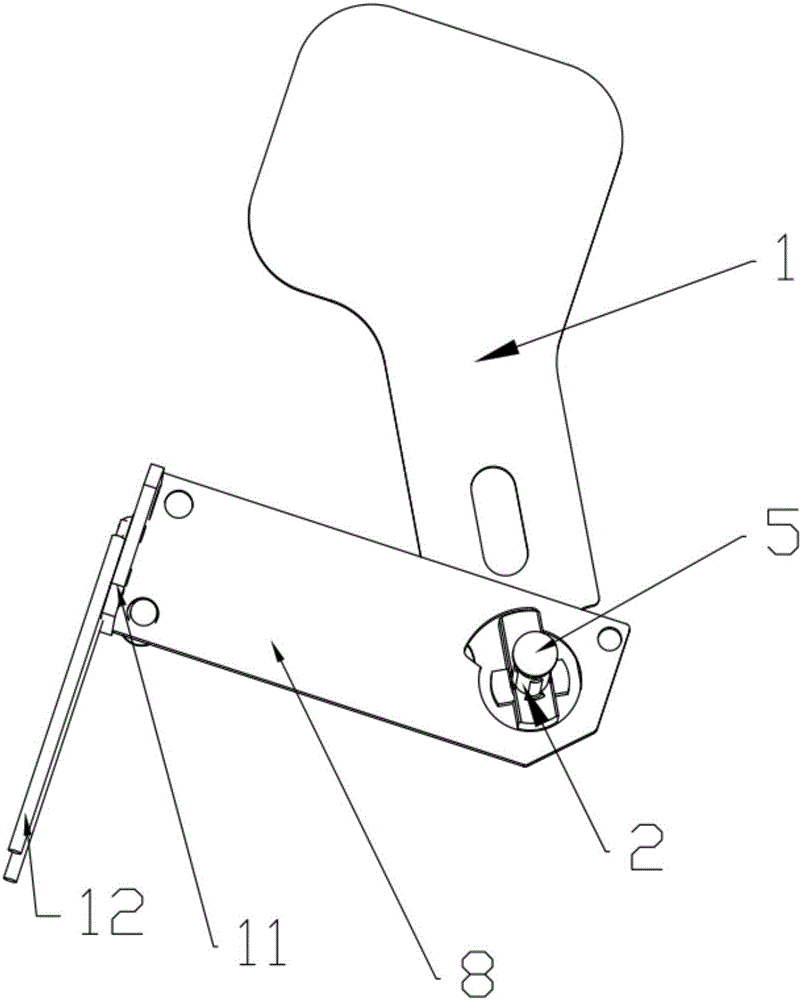

[0028] Such as Figure 1 to Figure 9 as shown, figure 1 It is a schematic diagram of the overall structure of a shutter switcher for infrared thermal imager technology according to the present invention, figure 2 It is a schematic diagram of the internal structure of a shutter switcher for infrared thermal imager technology according to the present invention, image 3 It is another schematic diagram of the internal structure of a shutter switcher for infrared thermal imager technology according to the present invention, Figure 4 It is a schematic structural diagram of the shutter cooperation part of a shutter switcher for infrared thermal imager technology according to the present invention, Figure 5 It is a schematic diagram of the swing shaft structure of a shutter switcher for infrared thermal imager technology according to the present invention, Figure 6 It is a schematic diagram of the shutter structure of a shutter switcher for infrared thermal imager technology a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com