AGV cluster positioning method based on pulse ultra wide band technology and AGV scheduling method

A pulse ultra-broadband, positioning method technology, applied in the field of positioning and navigation, can solve the problems of unacceptable accuracy, difficult cluster scheduling, technology failure to realize real-time positioning and batch scheduling, and achieve the effect of avoiding collisions and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0038] A kind of AGV (automatic guided vehicle) cluster positioning method based on pulse ultra-wideband technology of the present invention comprises the steps:

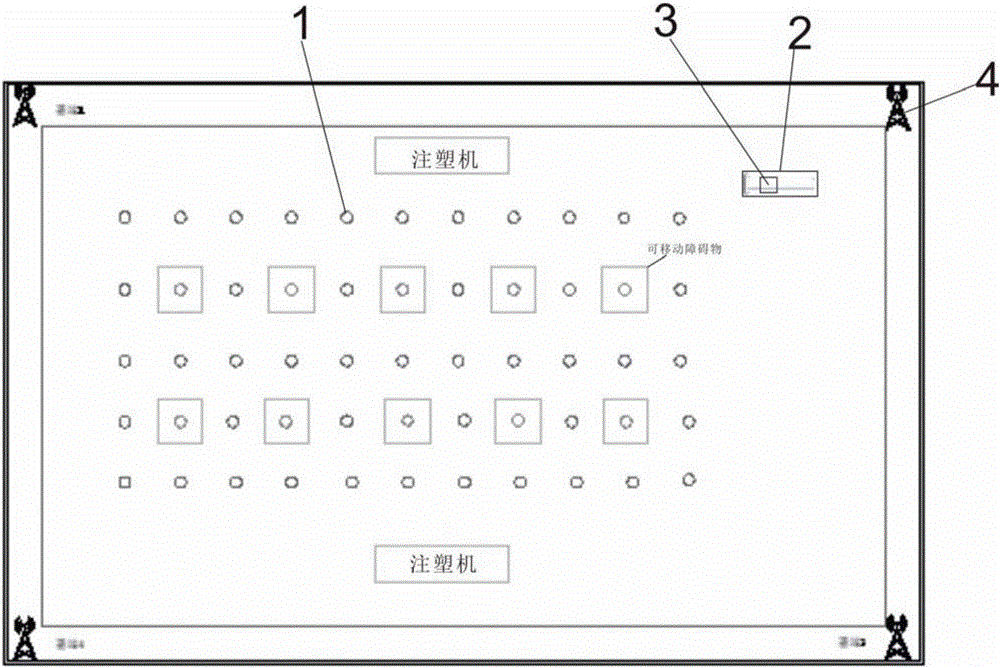

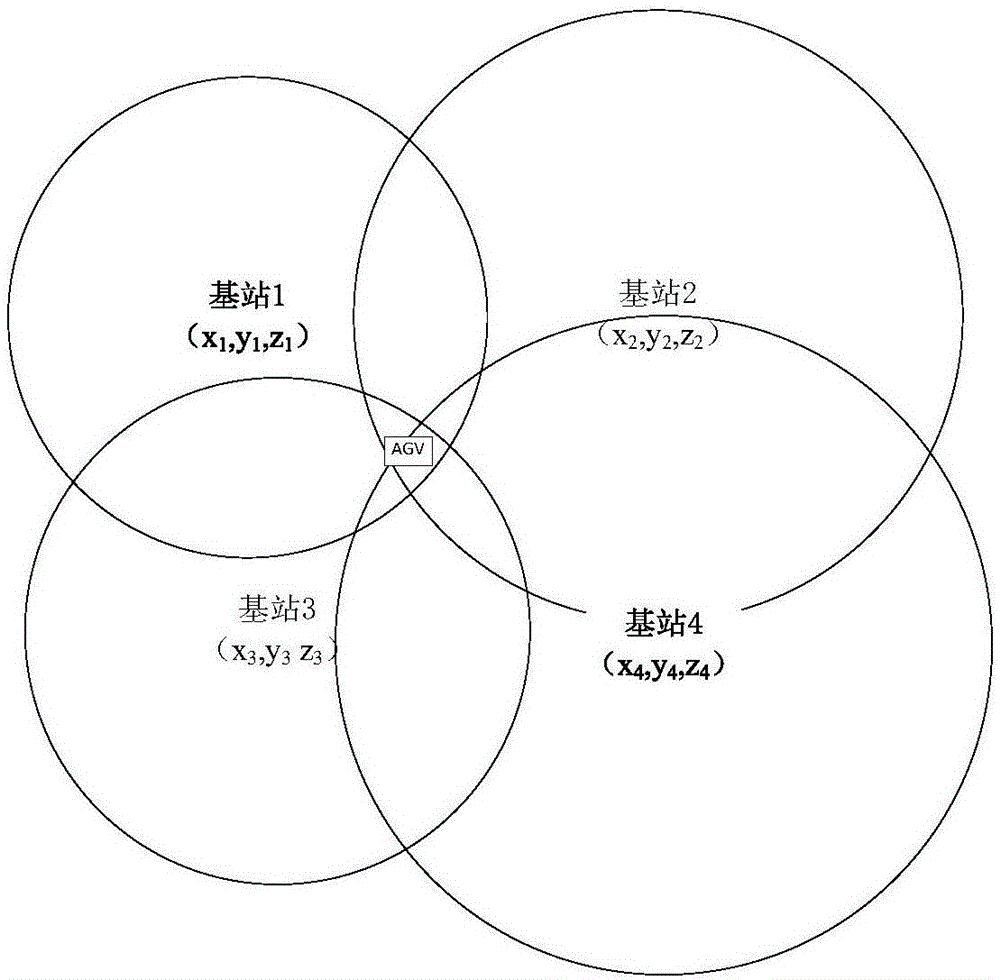

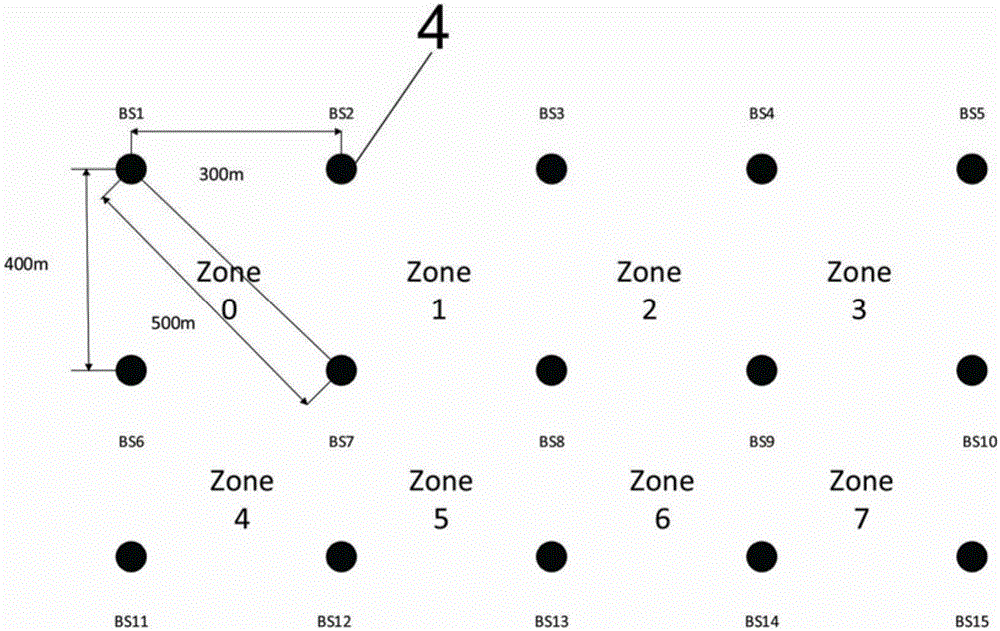

[0039] Step 1, at least four base stations 4 are distributed at the AGV guiding magnetic nail matrix on the factory floor, and UWB (carrier-free communication) wireless sensors are arranged on the base station 4; the ultra-wideband pulse wave by receiving and feeding back the base station is set on the AGV 2 UWB Tag Sensor 3 ( figure 1 shown); establish a three-dimensional coordinate system (x, y, z), and set the coordinates (x 1 ,y 1 ,z 1 ) is set as the base point, and the coordinates (x 2 ,y 2 ,z 2 ), (x 3 ,y 3 ,z 3 ), (x 4 ,y 4 ,z 4 ) as the reference point ( figure 2 shown);

[0040] Step 2. Calculate the position of the AGV in motion according to the obtained co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com