Hollow ring structure and its processing method

A processing method and ring technology, applied in rings, clothing, jewelry, etc., can solve the problems of increasing economic pressure on consumers and heavy rings, and achieve the effects of saving consumption, reducing prices, and increasing purchasing desire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

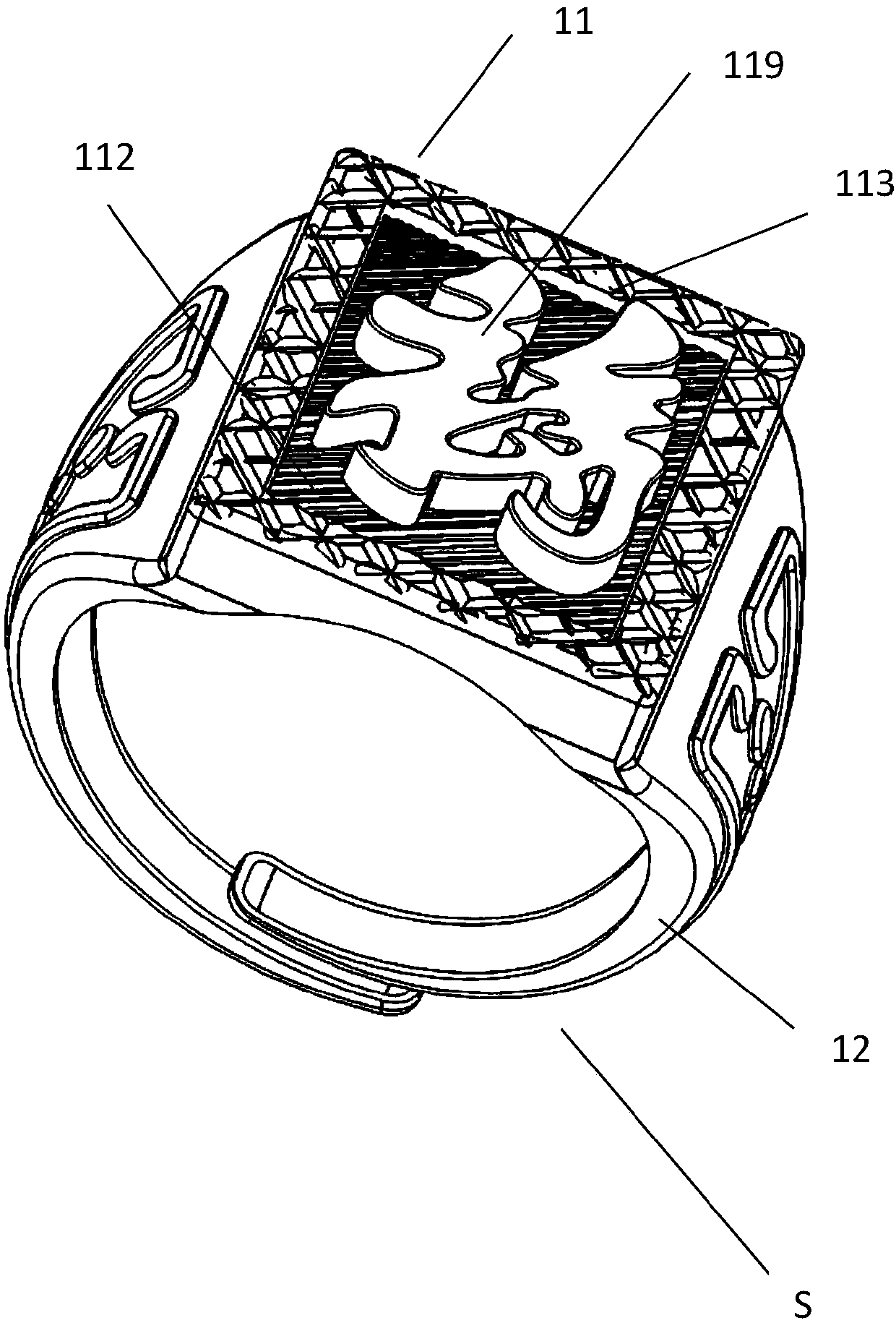

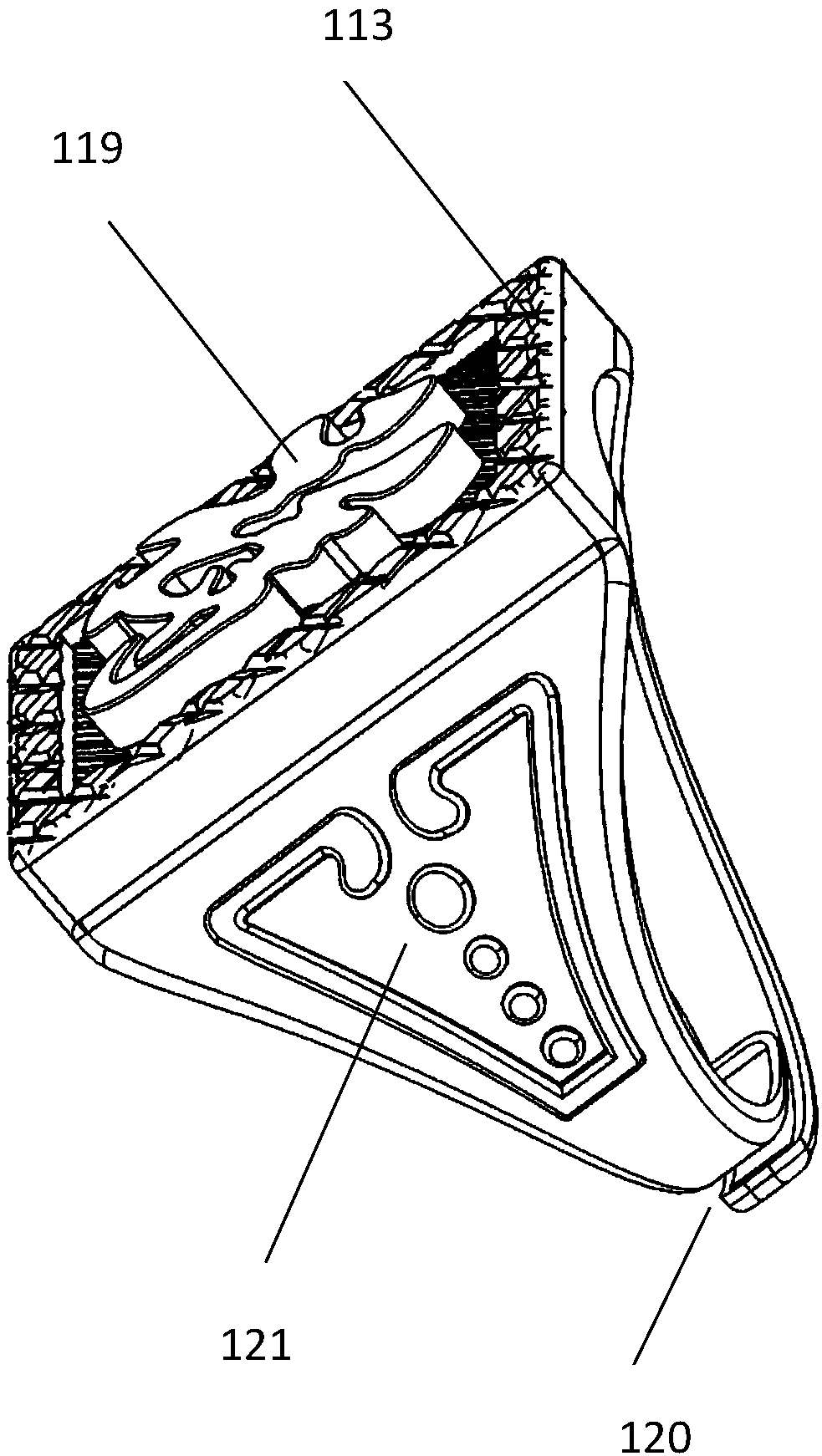

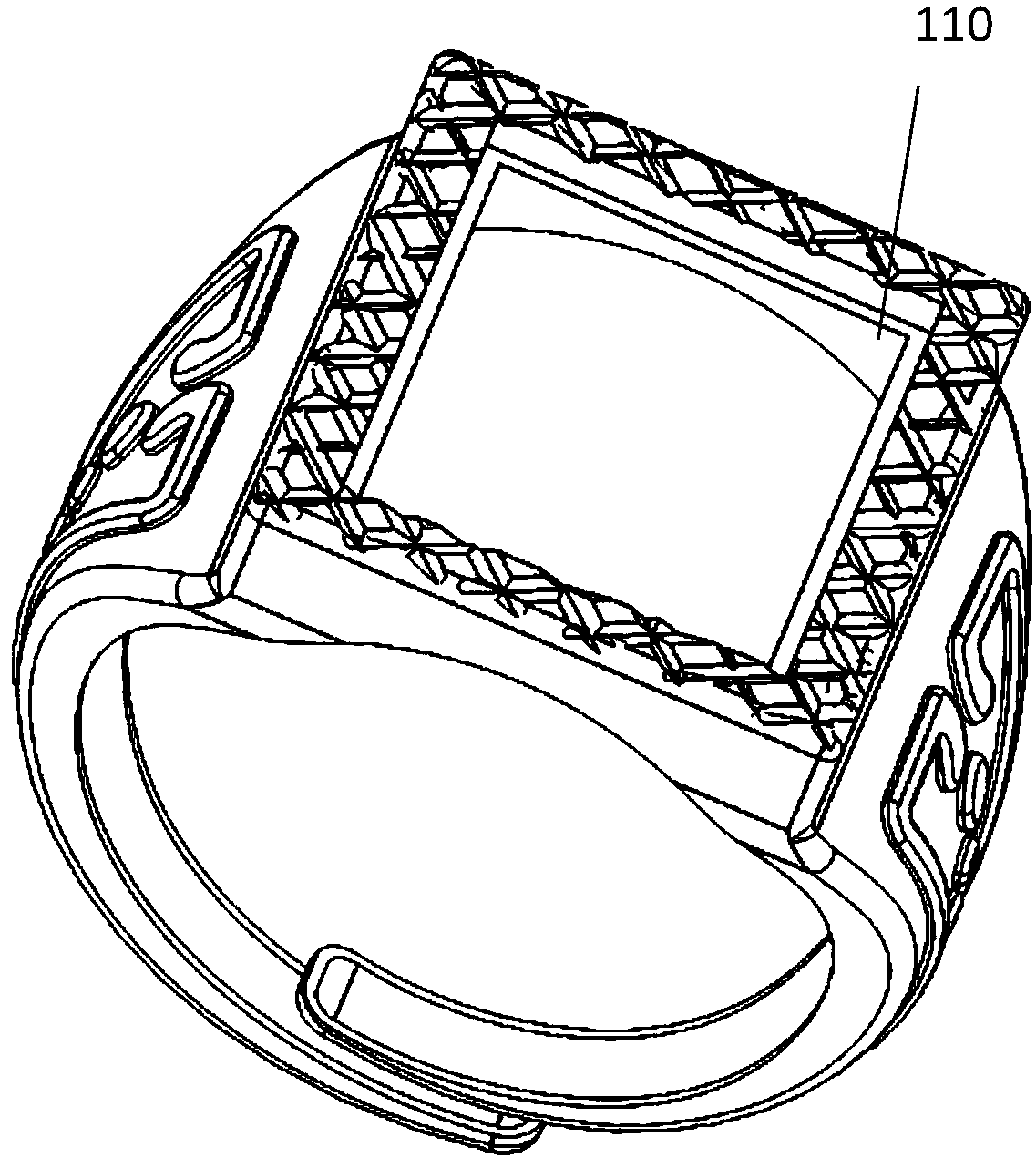

[0046] Such as Figure 1 to Figure 6 As shown, the hollow ring structure S of the present invention includes a ring body 10 provided with a crown portion 11 and an annular portion 12; Insert 20; the inner insert 20 and the inner surface of the ring body 10 form a smooth inner surface. The annular portion 12 in this embodiment is provided with an opening 120 with an overlapping portion. In the present embodiment, the inner concave cavity is composed of a through hole 110 and a bottom plate 112 that communicate front and rear. The front side is provided with a decorative part (that is, the word "Fu"), and the rear side of the bottom plate 112 constitutes the inner concave cavity. The inner concave cavity extends toward both sides wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com