Pipeline-type intelligent steam machine

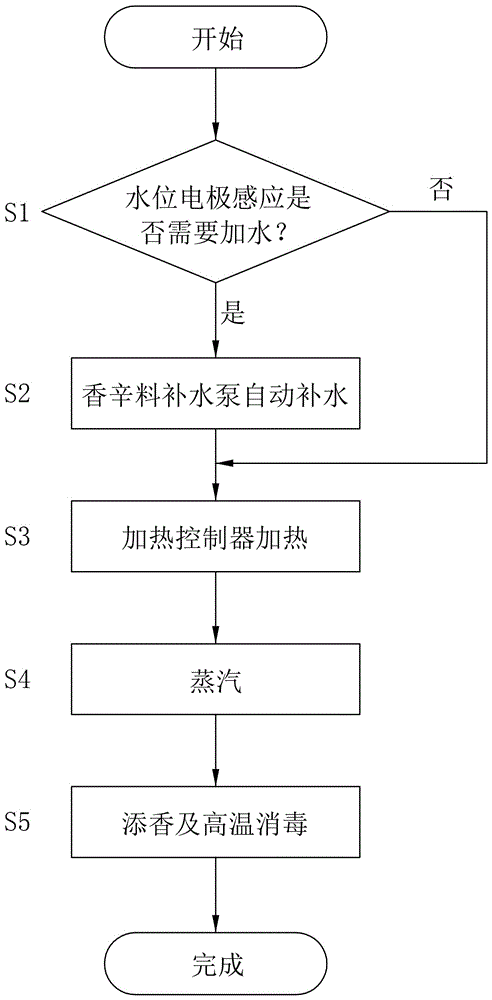

A steam engine and pipeline-type technology, which is applied to steam cooking utensils, timing control ignition mechanisms, heating devices, etc., can solve problems such as insufficient water, the inability of the steam engine to add spices independently, and damage to the steam engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

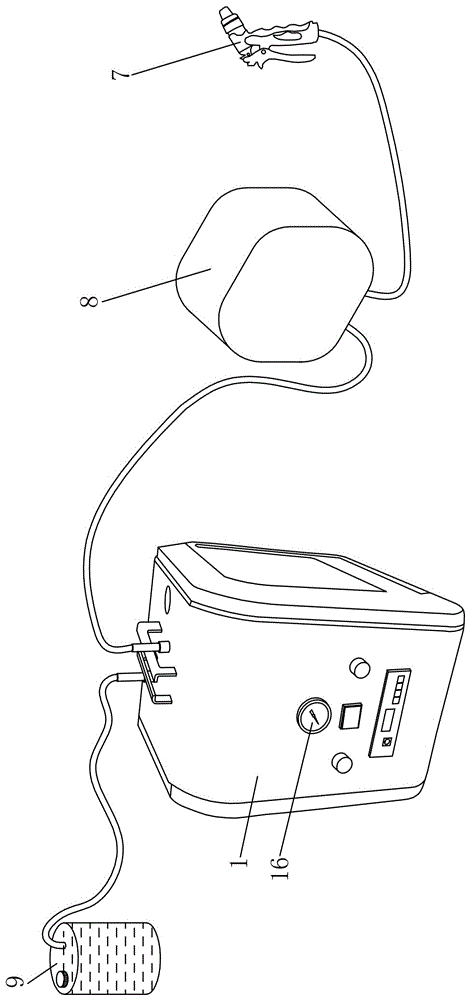

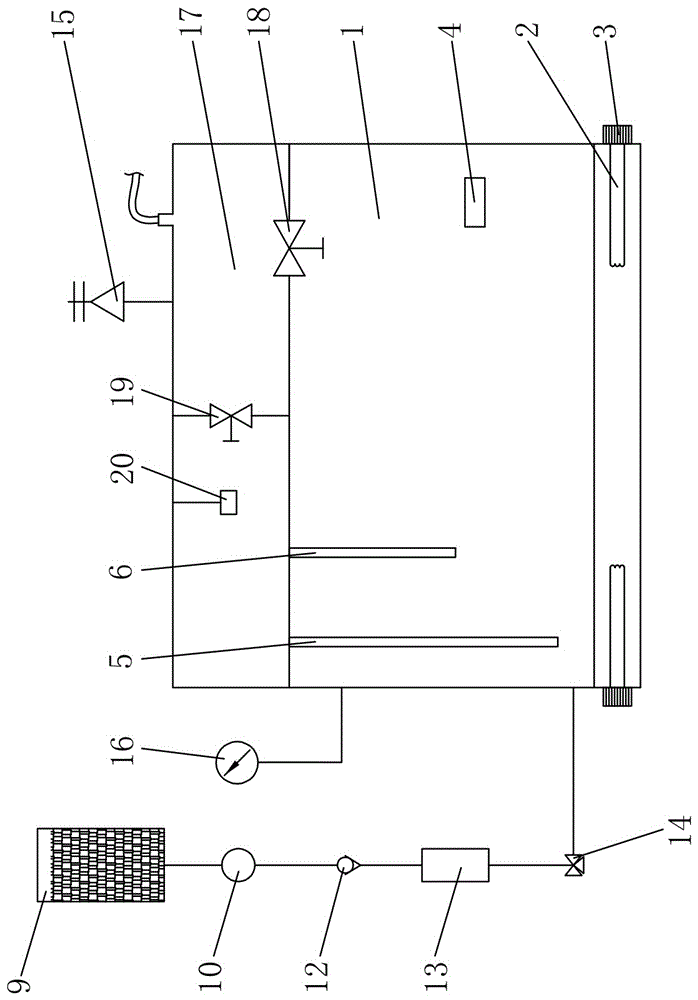

[0019] The pipeline type intelligent steam engine of the present invention comprises a heating box 1, a heating element 2 arranged at the bottom of the heating box 1, a heating controller 3 connected to the heating element 2 is arranged on the heating box 1, the feedback terminal of the heating controller is connected with the control The devices are connected, the heating box 1 is provided with a temperature sensor 4 connected to the heating controller 3, the heating box 1 is provided with a low water level electrode 5 and a high water level electrode 6 extending into the heating box 1, and the low water level electrode 5 is provided with The first signal feedback terminal and the second signal feedback terminal, the first signal feedback terminal is connected to the heating controller 3 . The heating box 1 is provided with a spice adding branch, and the spice adding branch includes a spice adding bucket 9, a circulation pump 10 connected with the spice adding bucket 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com