Drive control system for endoscope stapler

A transmission control and stapler technology, applied in medical science, surgery, surgical fixation nails, etc., can solve the problems of affecting the recovery effect, increasing the patient's burden, uneven force, etc., and achieve the effect of saving internal space structure and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

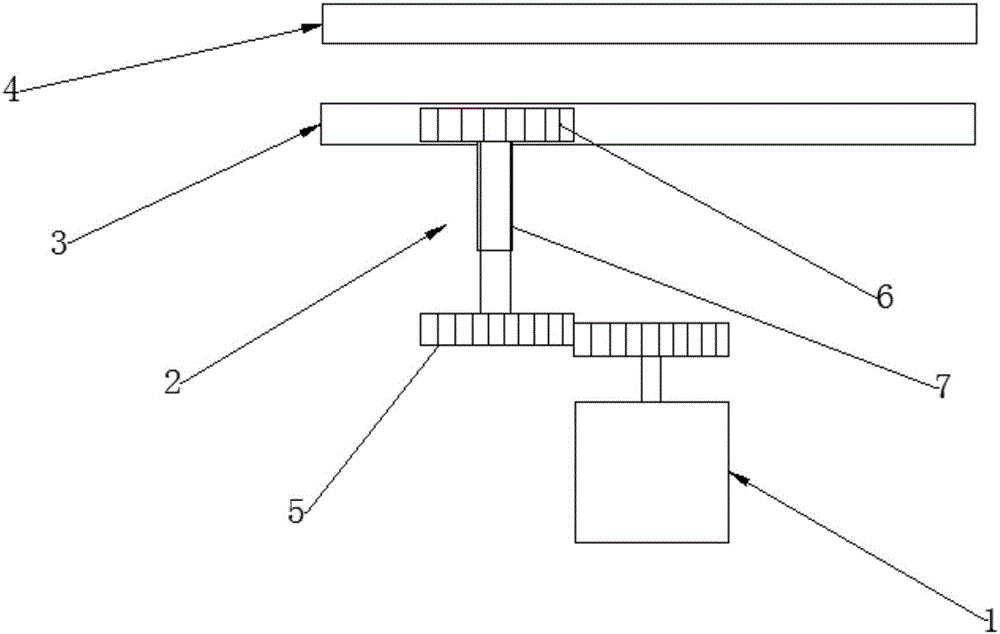

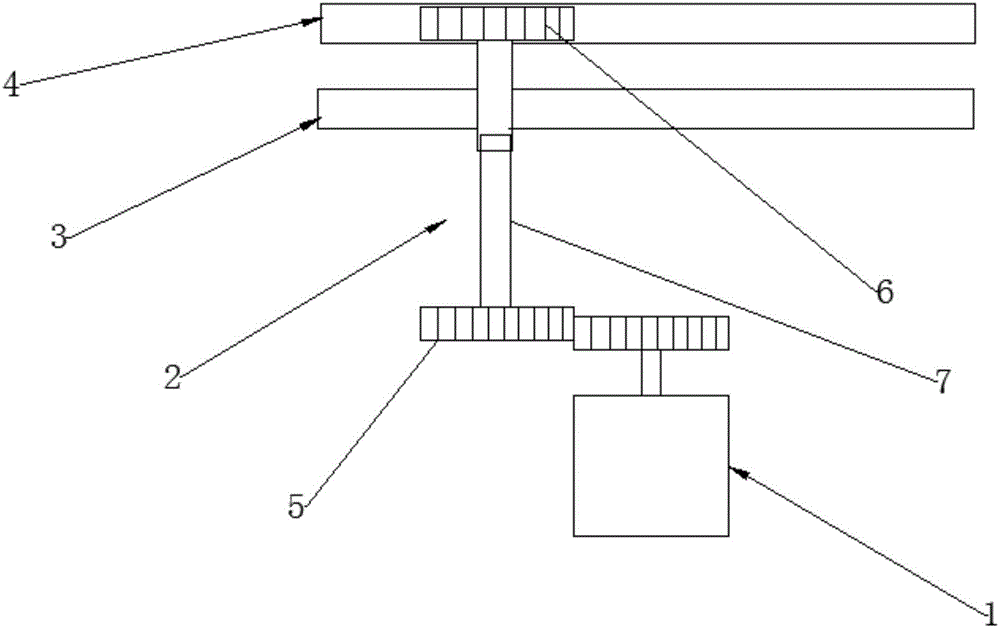

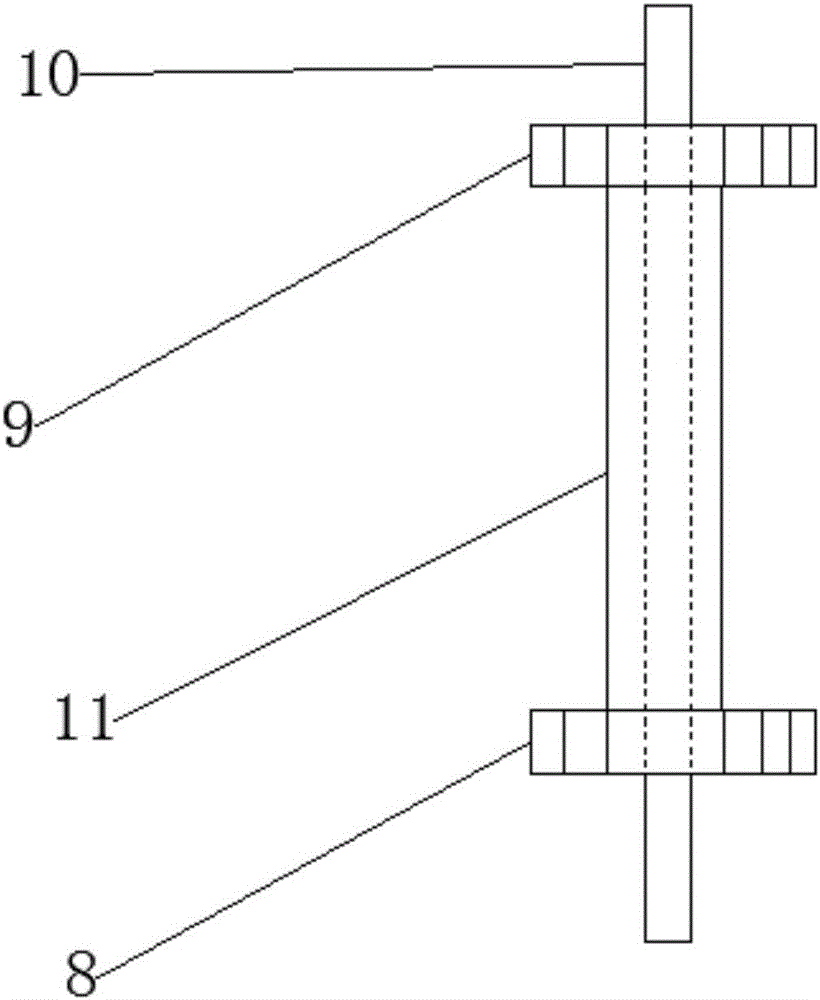

[0047] This embodiment provides a transmission control system of an endoscopic stapler, including a driving part 1, a transmission conversion part 2, a first driven assembly 3 and a second driven assembly 4; the transmission conversion part 2 is a movable part and includes The first transmission part and the second transmission part, the first transmission part of the transmission conversion part 2 is always connected with the drive part 1; the second transmission part of the transmission conversion part 2 communicates with the first driven assembly 3 and the second The transmission part drives the first driven assembly 3, and the first driven assembly 3 controls the first series of transmission control actions of the endoscopic stapler; after the transmission conversion part 2 performs A action, the second transmission part and the second driven The assembly 4 is connected and the second transmission part drives the second driven assembly 4, and the second driven assembly 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com