A badminton racket handle and its manufacturing method

A badminton racket and its manufacturing method are applied in the field of sports equipment, badminton racket handle and its manufacturing field, which can solve the problems that the production accuracy is difficult to achieve consistency, the weight is not easy to control, and waste wood resources, etc., and achieve light weight, The effect of stable strength and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

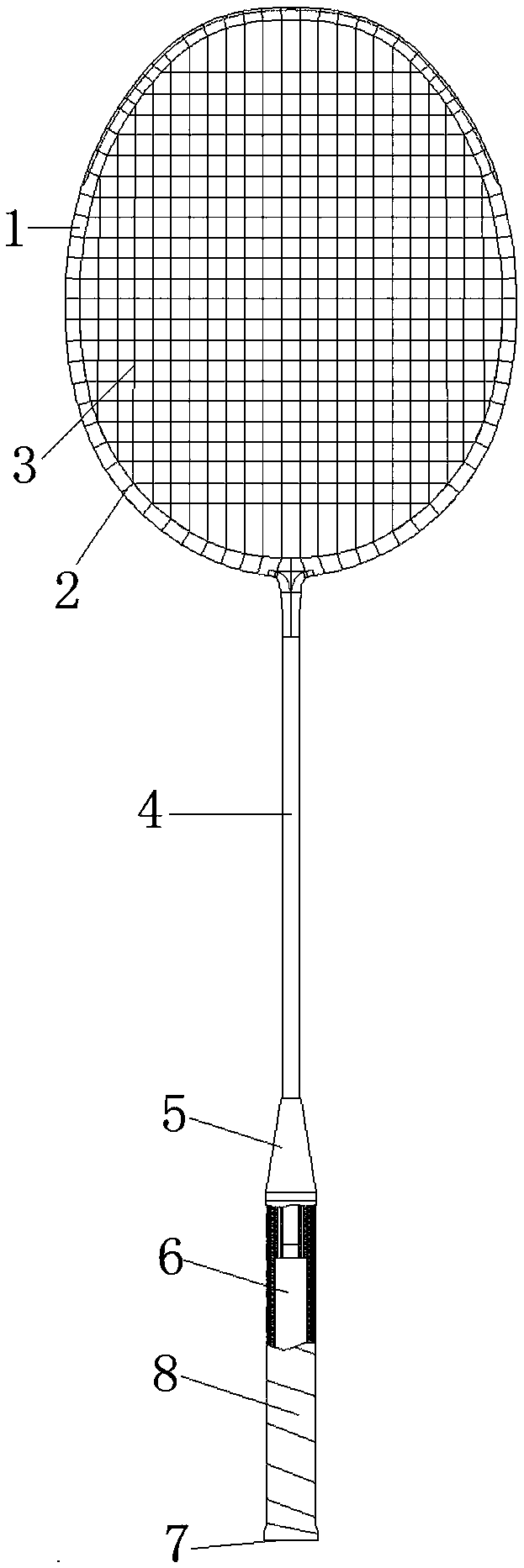

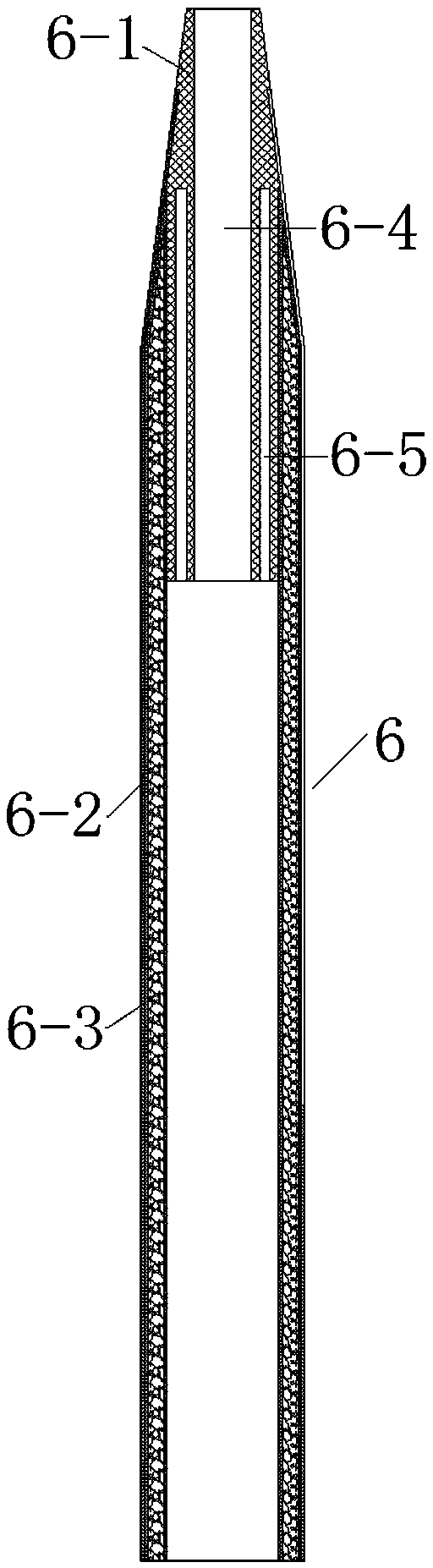

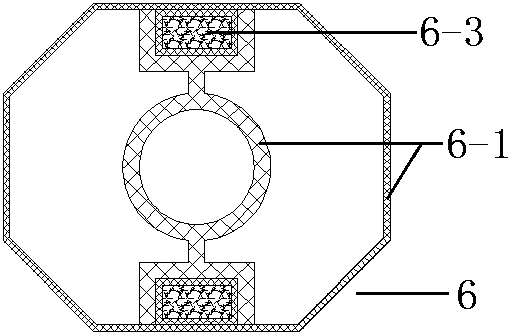

[0034] Refer to attached figure 1 , figure 2 , image 3 , A kind of badminton racket that the present invention makes comprises racket racket frame 1, string guard nail 2, racket line 3, racket shaft 4, front cover 5, handle 6, back cover 7 and handle skin 8. The front end of the handle 6 of the racket is provided with a front cone, and the front cone is molded by injection molding with nylon and rubber materials, and the centrality and warpage of the front cone can be controlled below 1mm. After sandblasting the front cone, apply a layer of resin evenly on the surface, fill the cut PU powder on both sides and the groove of the front cone, wrap the carbon fiber composite material prepreg cloth coated with resin, and then put the front cone The positioning pin is inserted into the center hole of the front cone, and the front cone preform is completed; the carbon handle is rolled with the cut carbon fiber prepreg cloth, and then according to the structural design sheet, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com