Patents

Literature

30results about How to "Guaranteed usage period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink jet ink containing polyurethane dispersant

InactiveUS6136890AImprove resistanceRapid dryingDuplicating/marking methodsInksPolymer chemistryPigment

Described are pigmented inks comprising a liquid medium, a pigment, and a polyurethane dispersant, the pigment being stabilized by the polyurethane dispersant, and the ink being suitable for use in an ink jet printer.

Owner:3M INNOVATIVE PROPERTIES CO

Nanowire dispersion compositions and uses thereof

ActiveUS20060257637A1Minimize aggregationFacilitate manipulationMaterial nanotechnologyMixing methodsHydrophilic-lipophilic balanceNanometre

Nanowire dispersion compositions (and uses thereof) are disclosed comprising a plurality of inorganic nanowires suspended in an aqueous or non-aqueous solution comprising at least one low molecular weight and / or low HLB (Hydrophile-Lipophile Balance) value dispersant. Methods of further improving the dispersability of a plurality of inorganic nanowires in an aqueous or non-aqueous solution comprise, for example, oxidizing the surface of the nanowires prior to dispersing the nanowires in the aqueous or non-aqueous solution.

Owner:ONED MATERIAL INC

Nanowire dispersion compositions and uses thereof

ActiveUS7745498B2Improve solubilityEasy to processMaterial nanotechnologyMixing methodsNanowireHydrophile

Nanowire dispersion compositions (and uses thereof) are disclosed comprising a plurality of inorganic nanowires suspended in an aqueous or non-aqueous solution comprising at least one low molecular weight and / or low HLB (Hydrophile-Lipophile Balance) value dispersant. Methods of further improving the dispersability of a plurality of inorganic nanowires in an aqueous or non-aqueous solution comprise, for example, oxidizing the surface of the nanowires prior to dispersing the nanowires in the aqueous or non-aqueous solution.

Owner:ONED MATERIAL INC

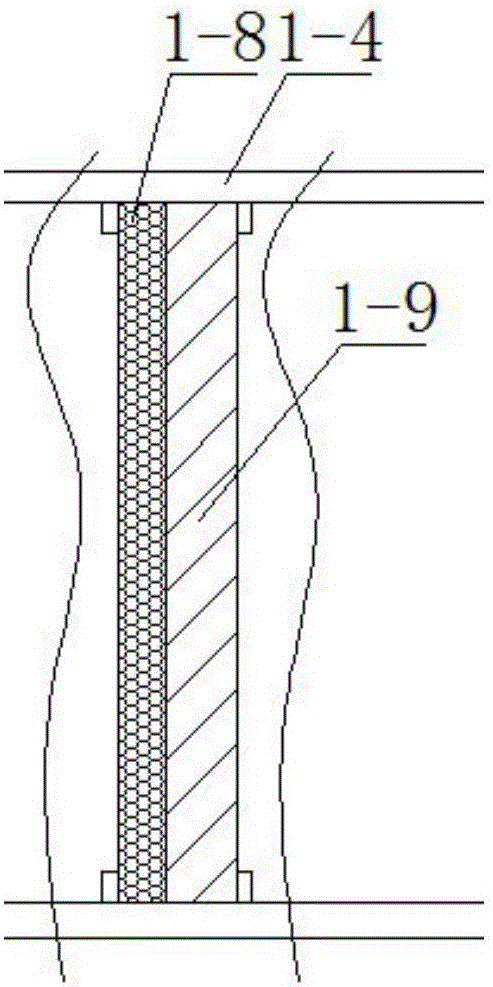

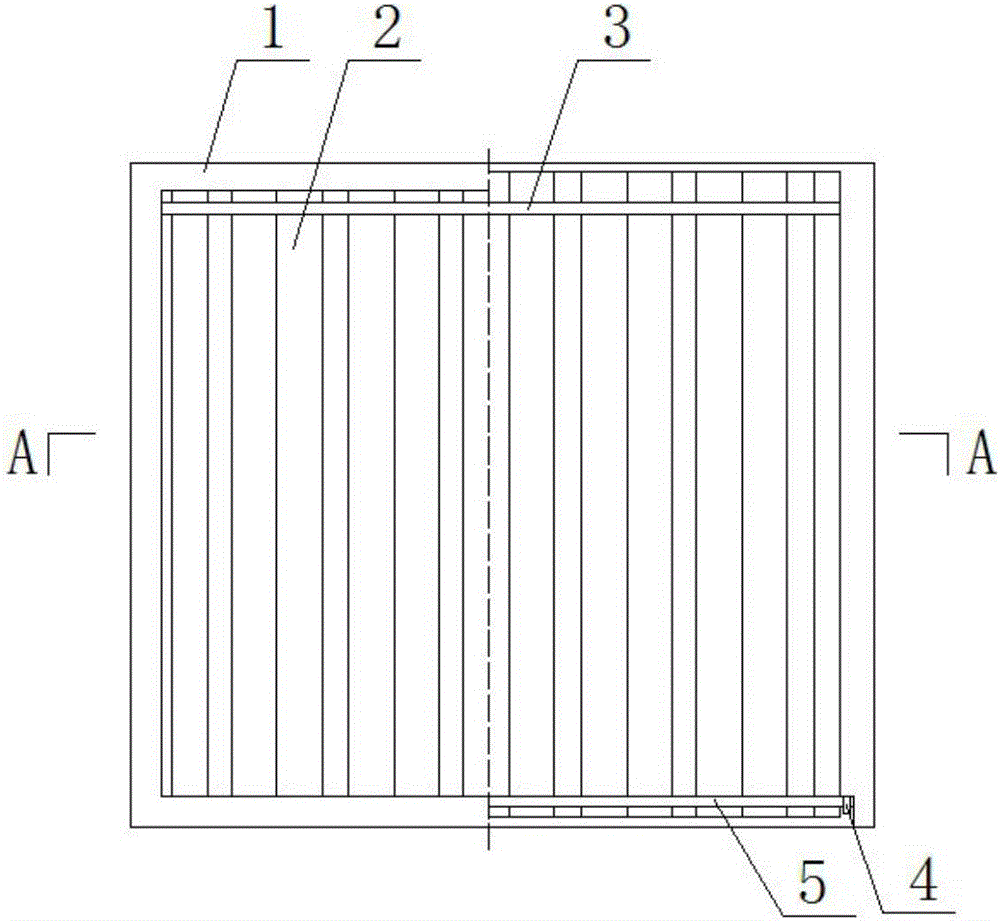

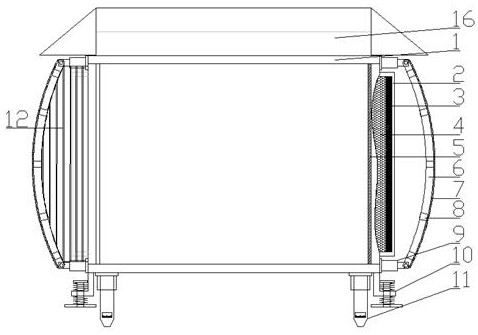

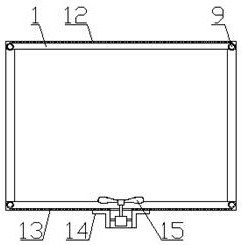

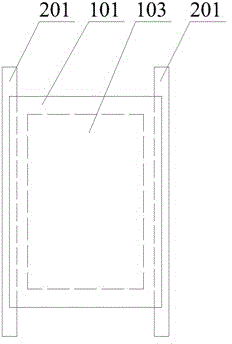

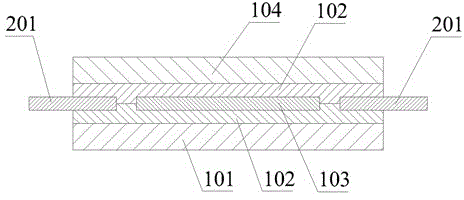

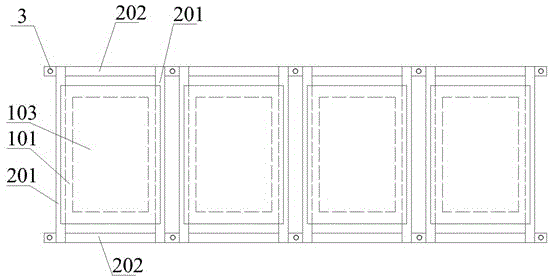

Flexible solar battery component and packaging method thereof

ActiveCN102856403ASufficient weather resistanceSufficient tensile failure strengthFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention relates to a flexible solar battery component and a packaging method thereof, belonging to the technical field of solar photovoltaic. The flexible solar battery component consists of an inner packaging layer, an outer packaging layer and a flexible solar battery chip, wherein glue films are arranged between the battery chip and the inner packaging layer and between the battery chip and the outer packaging layer; the battery chip is coated by the glue films; the periphery of the battery chip is provided with a hot-melting and welding flexible insulating layer; a part of area of the flexible insulating layer is embedded between the two layers of glue films for coating the battery chip and is packaged into a body with the battery chip; and the other part of area of the flexible insulating layer is convex out of the battery component. The battery components are hot-melted and welded into a whole body so as to form a flexible solar battery array. The invention has the positive effects that the battery array can be folded, the quantity and the area of the components can be increased randomly according to the need; and if the reduction or damage of the performance of one or more battery components occurs in the array, the defective battery components are cut for replacement.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD +1

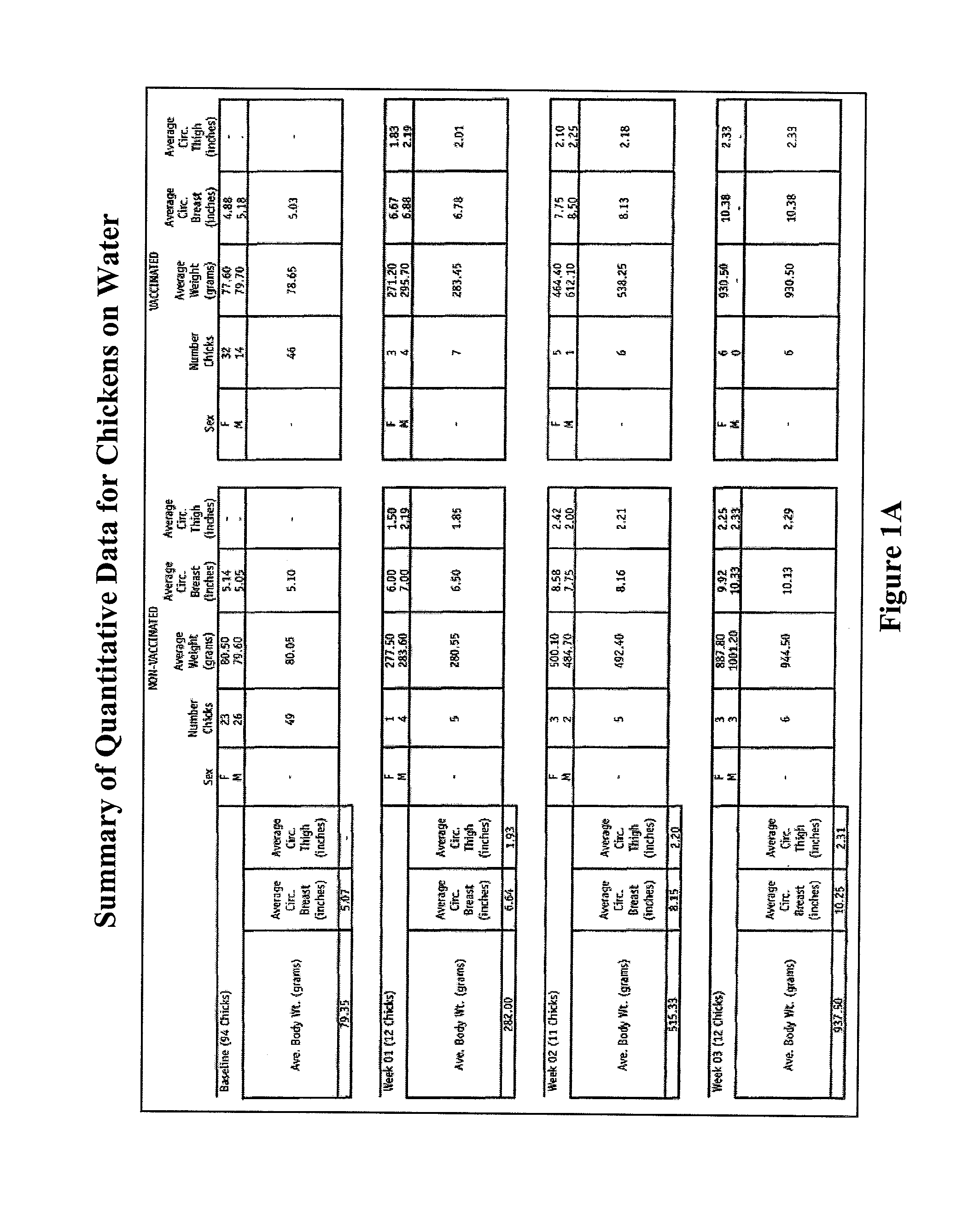

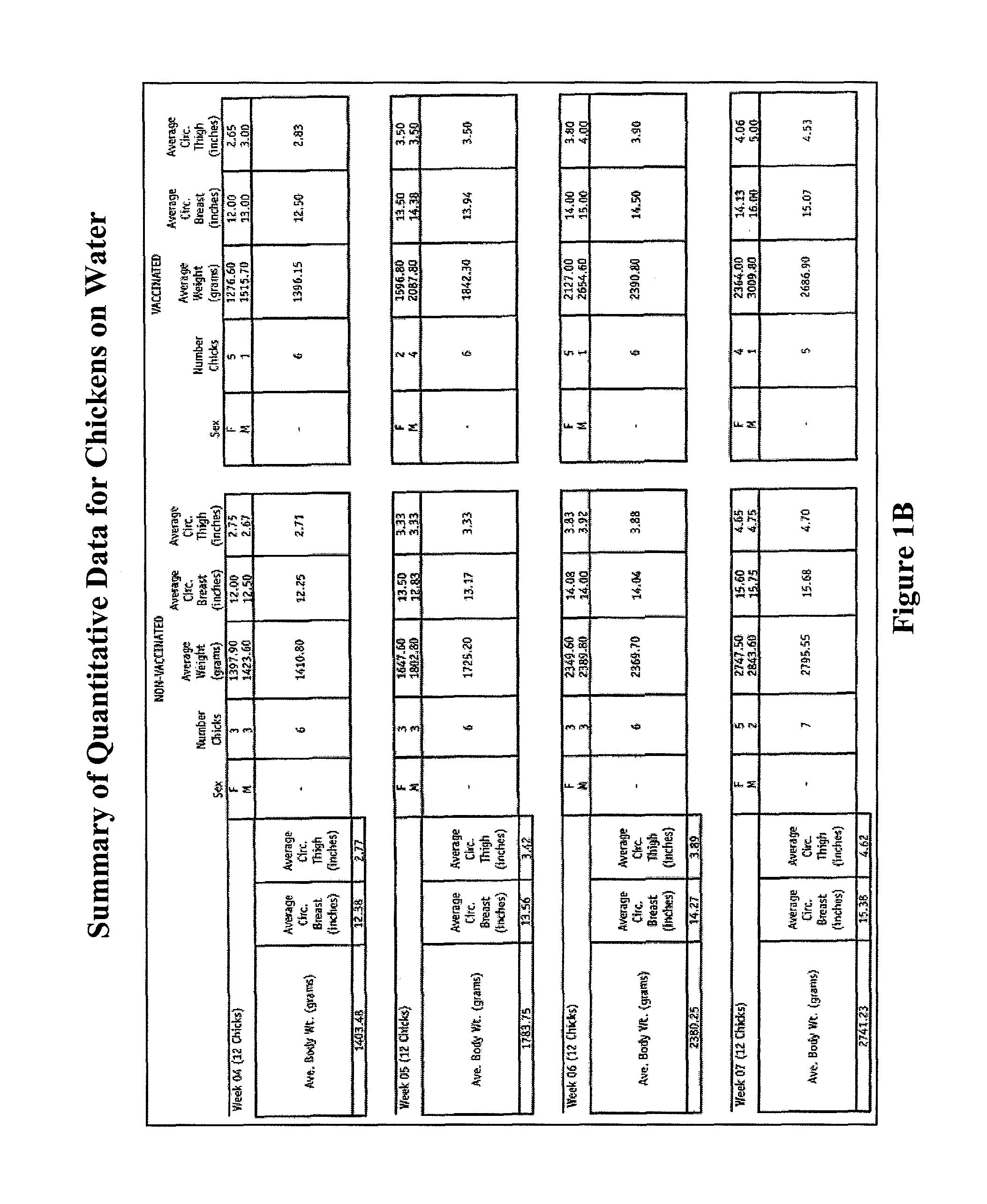

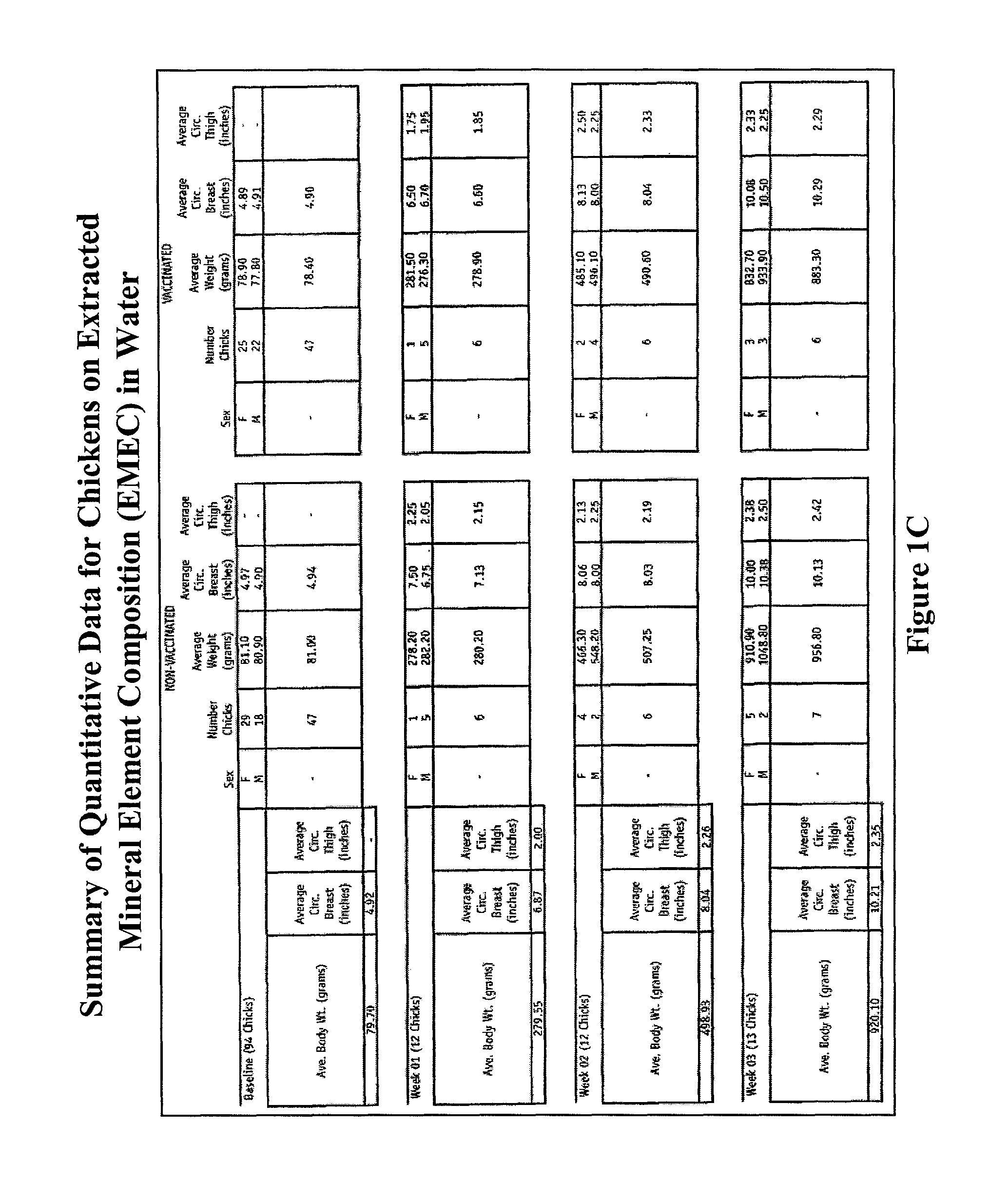

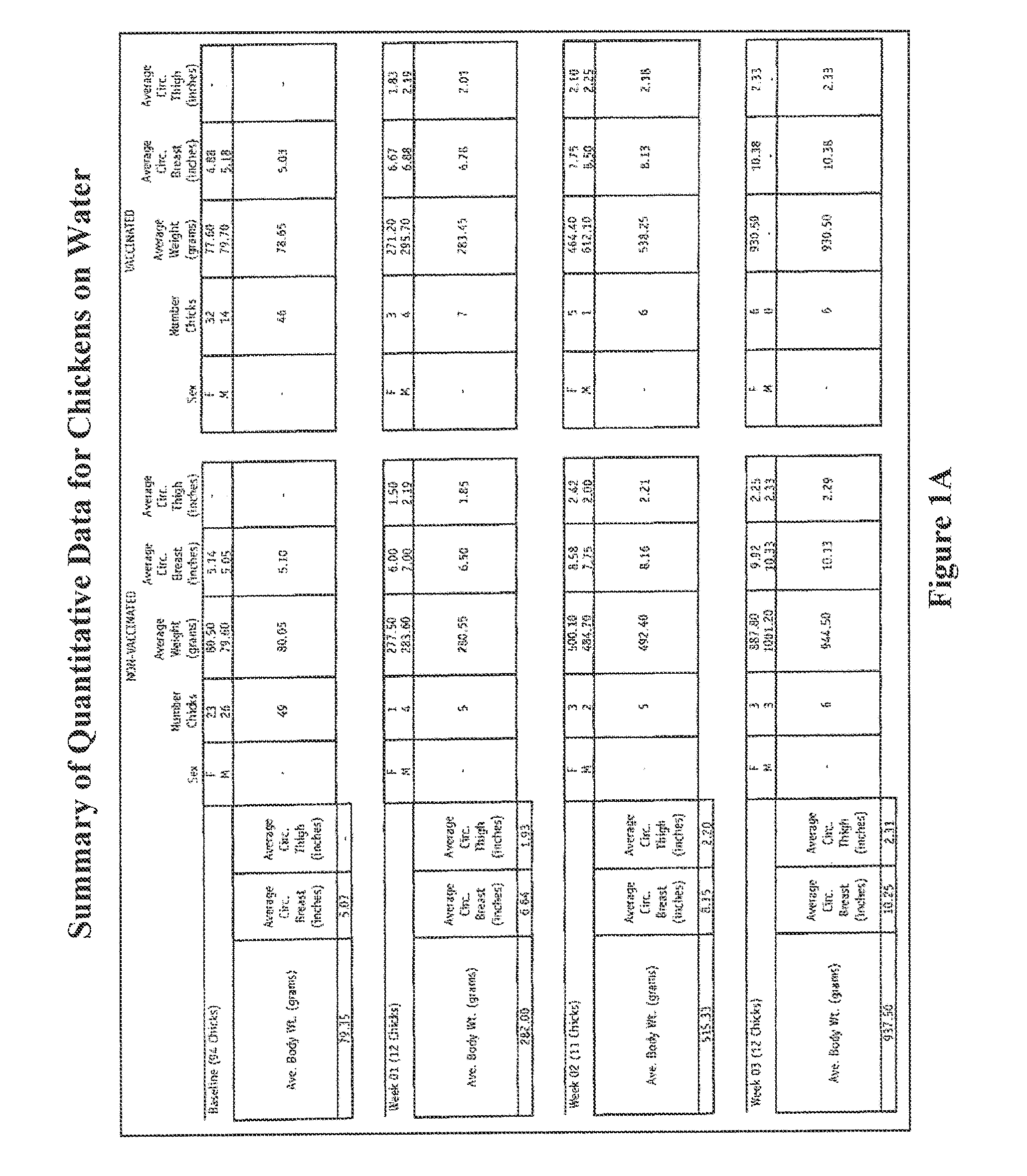

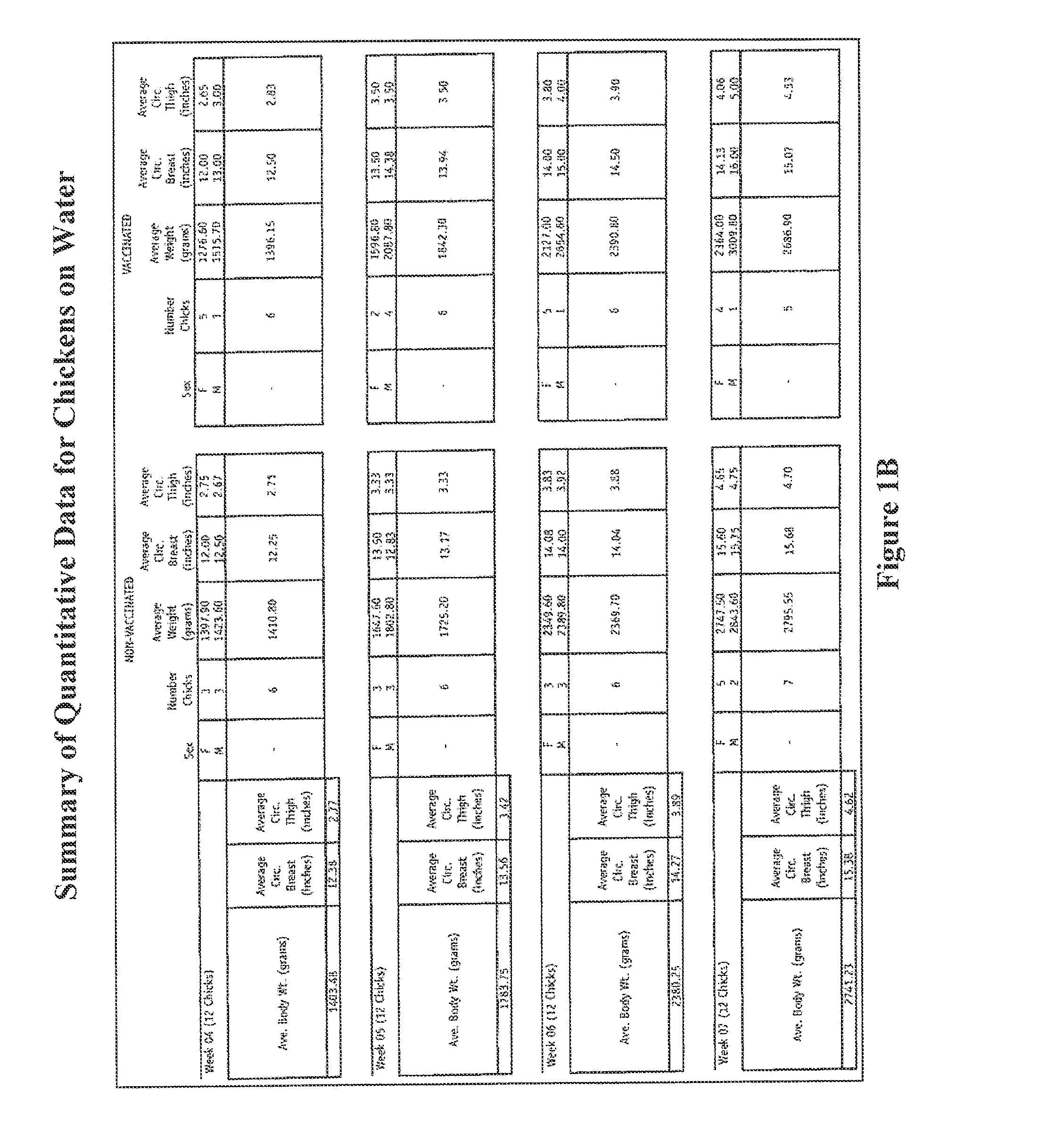

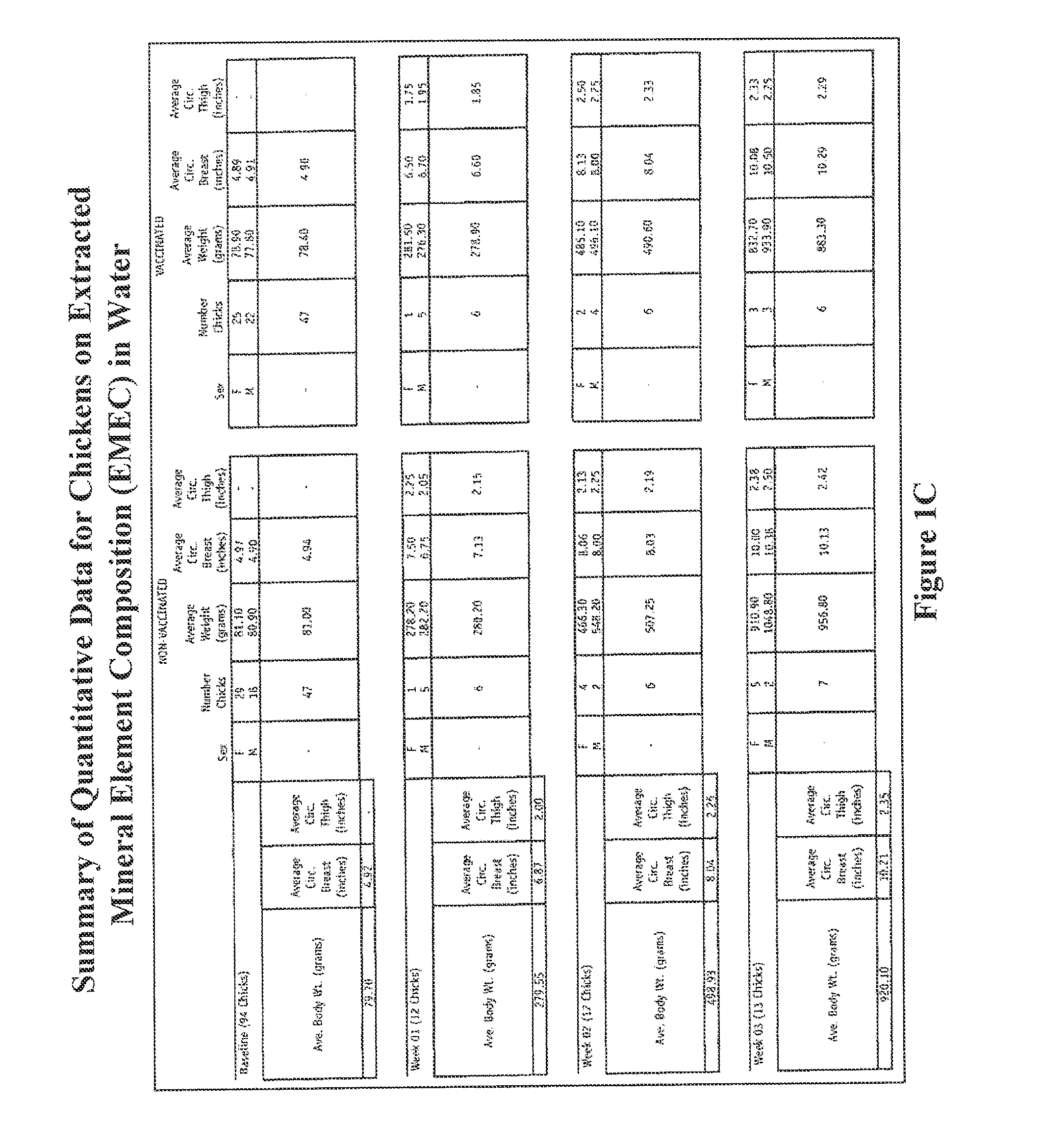

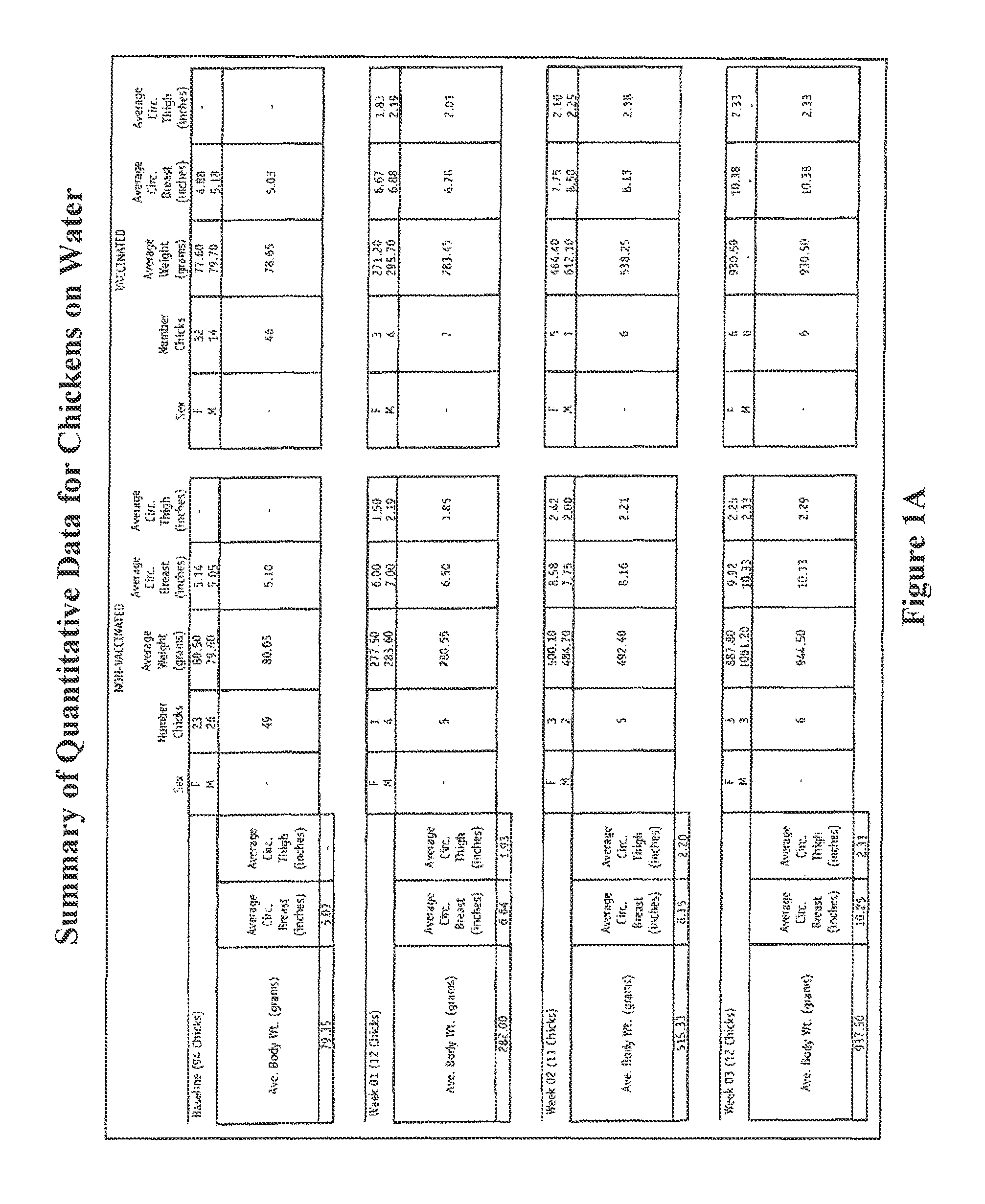

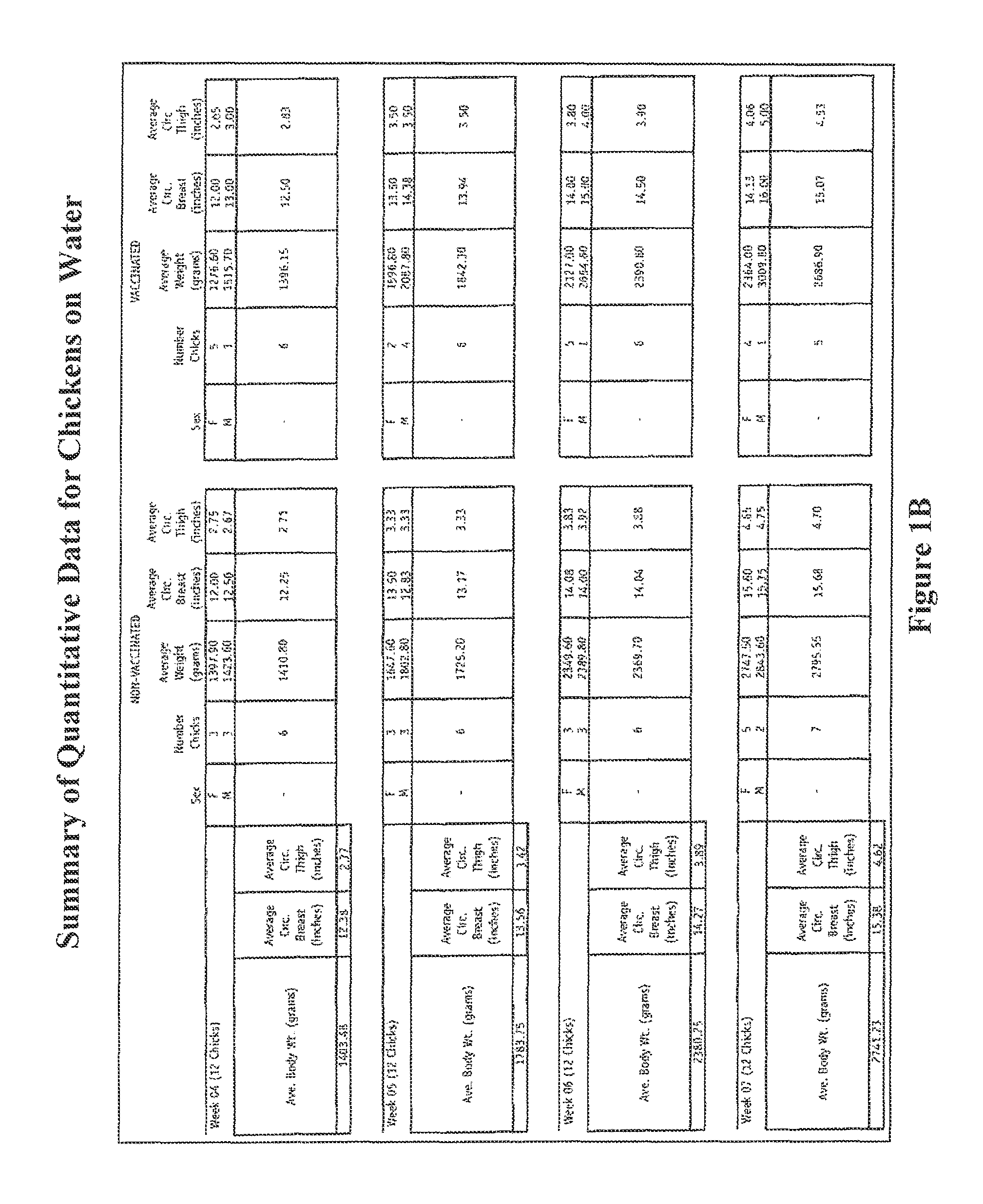

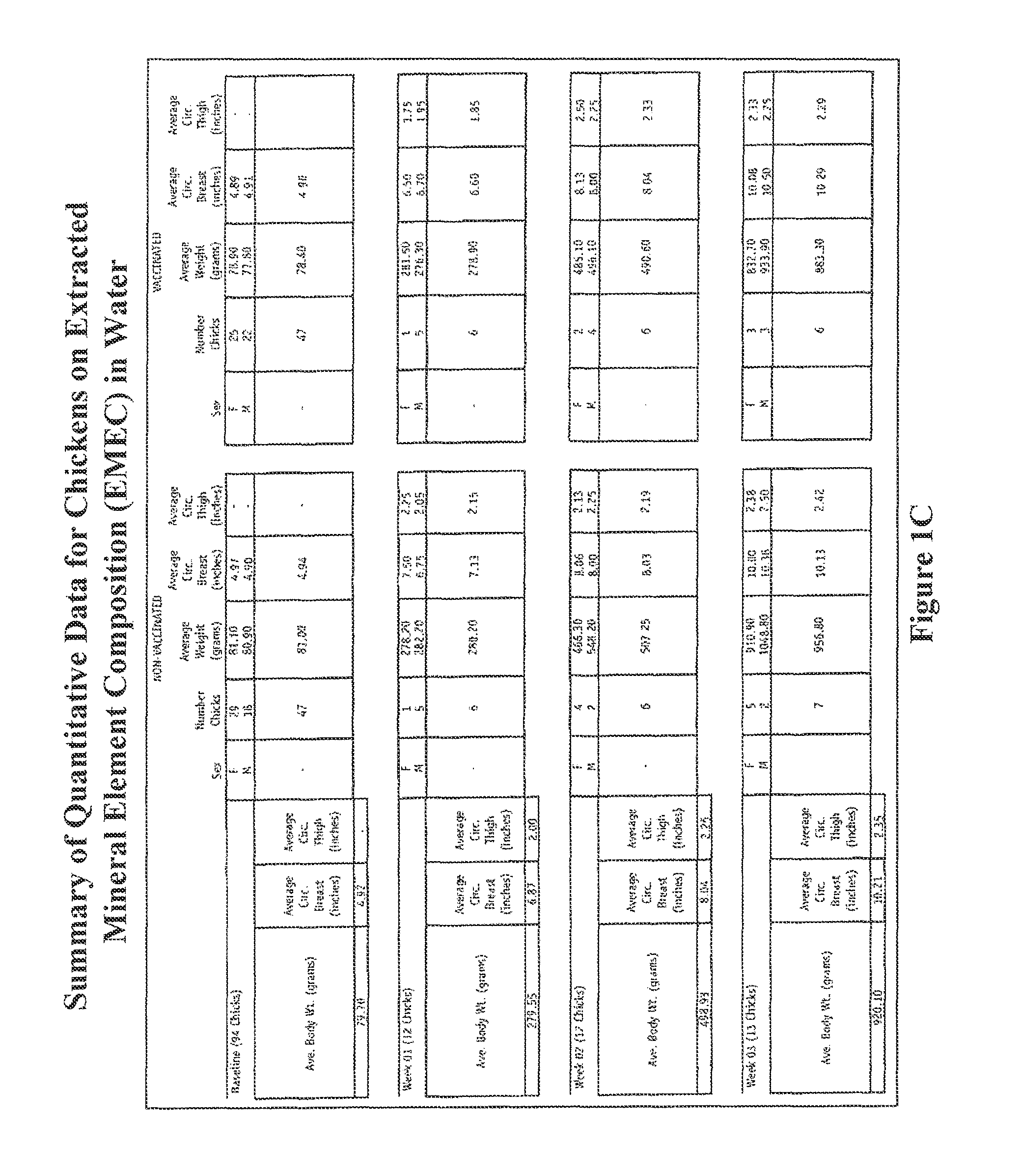

Methods and compositions for animal feed

ActiveUS9180141B1Increase the number ofIncrease egg productionInorganic phosphorous active ingredientsInanimate material medical ingredientsElement compositionIndividual animal

The present invention is directed to methods and compositions that are useful in producing, feeding and growing animals. Compositions of the present invention comprise an extracted mineral element composition as disclosed herein. Animal lifespan and production is improved when provided with compositions comprising an extracted mineral element composition.

Owner:CORE INTPROP HLDG

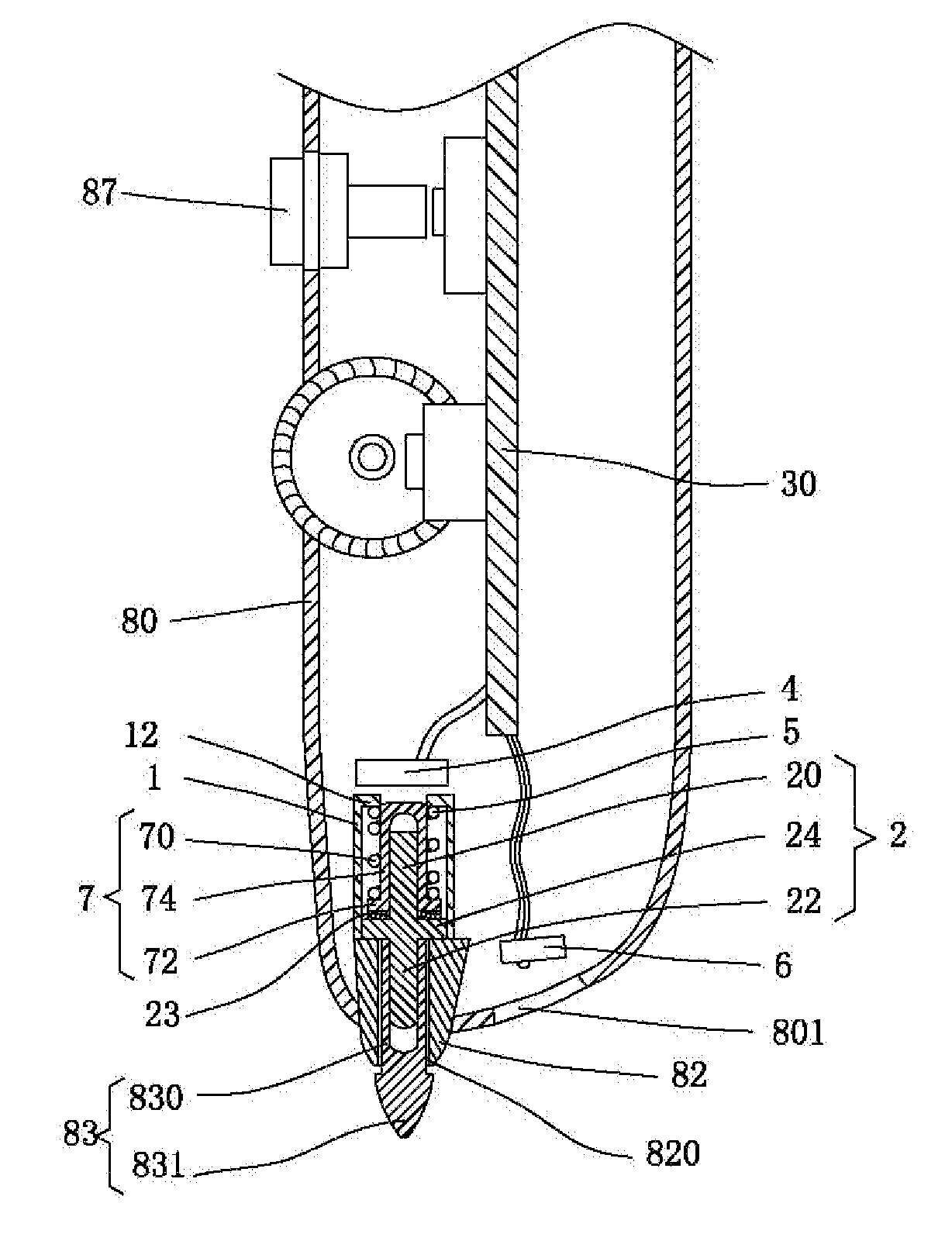

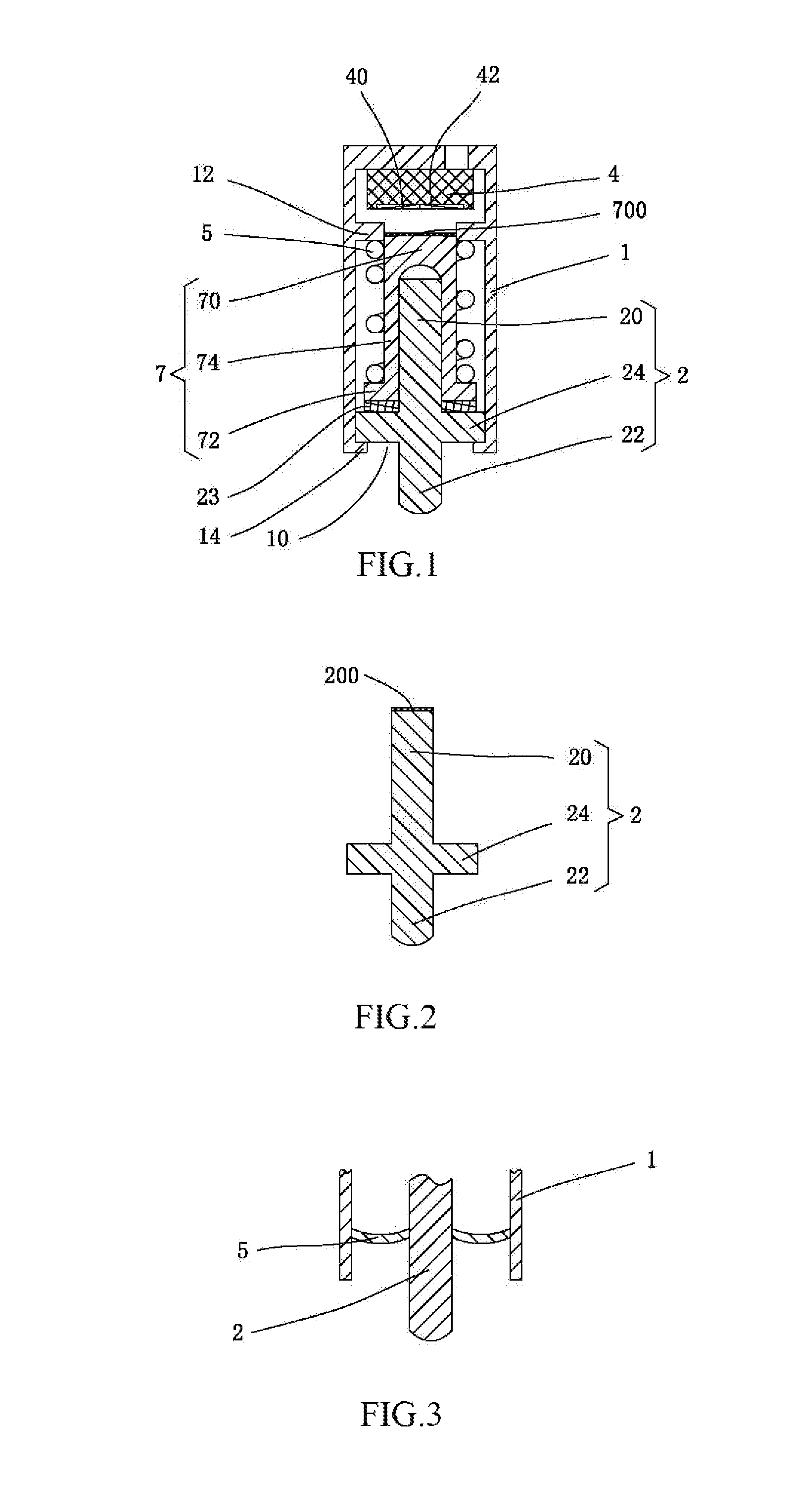

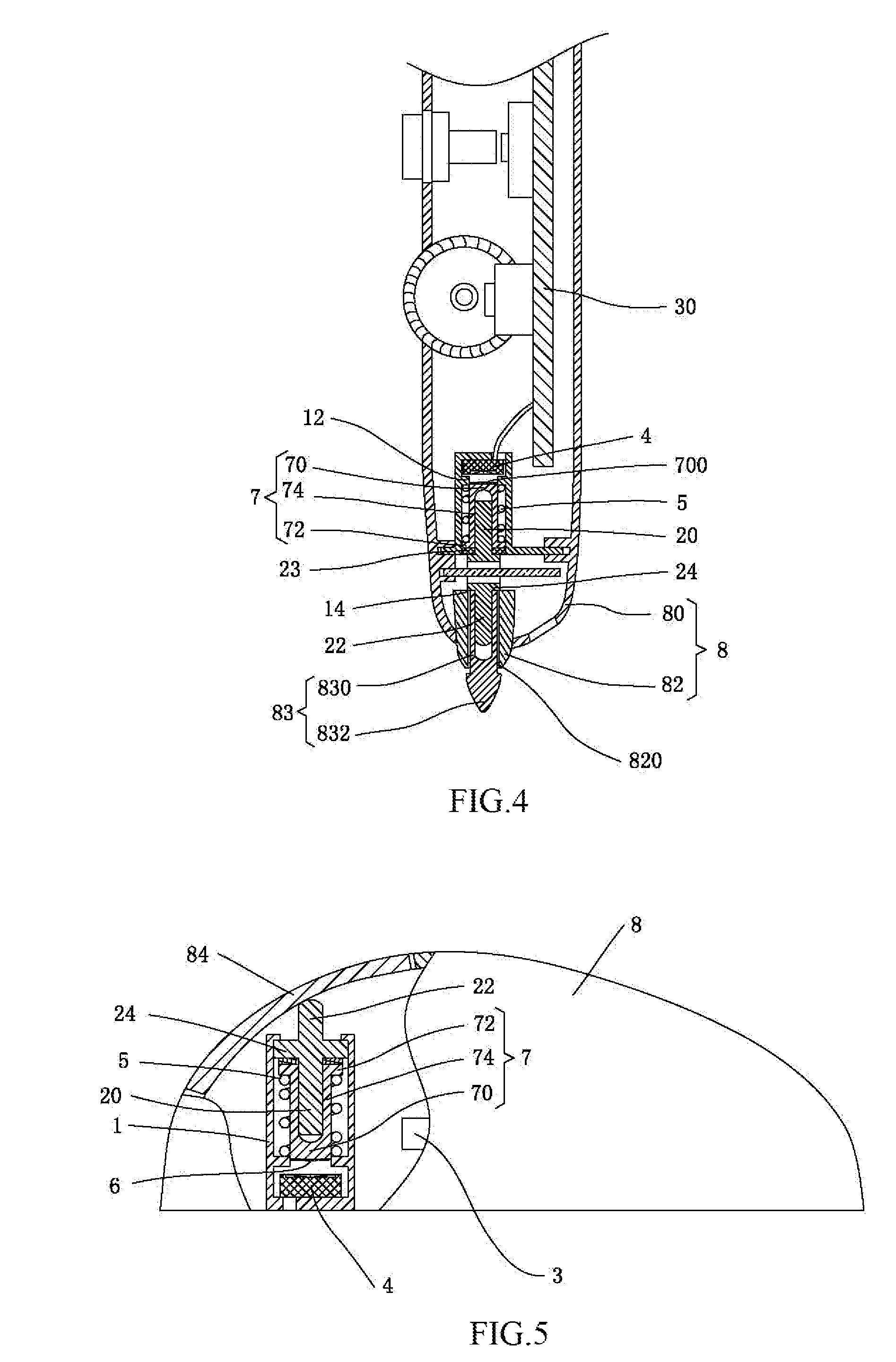

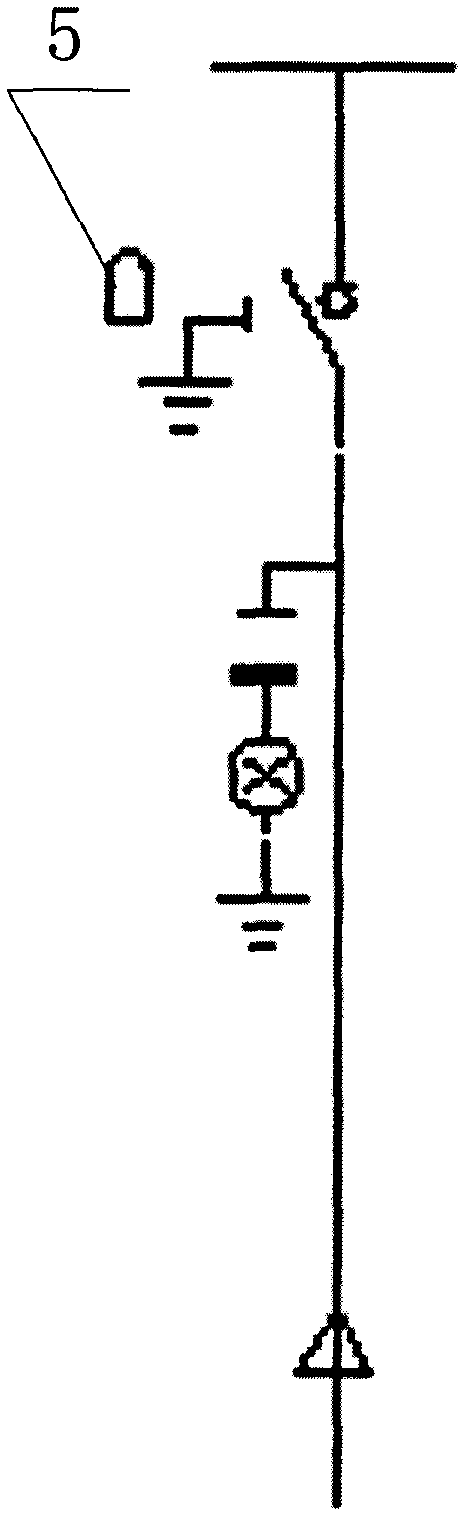

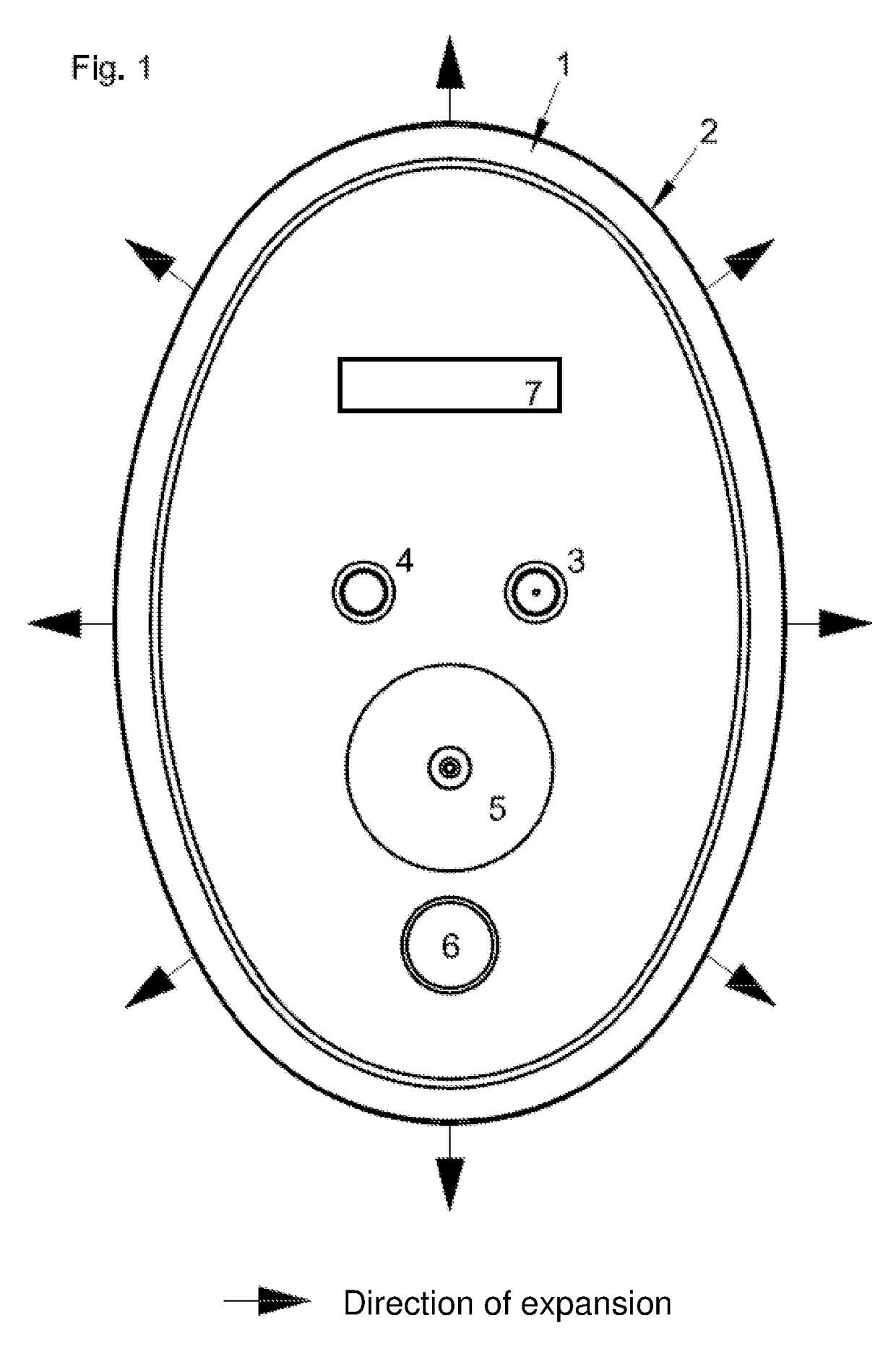

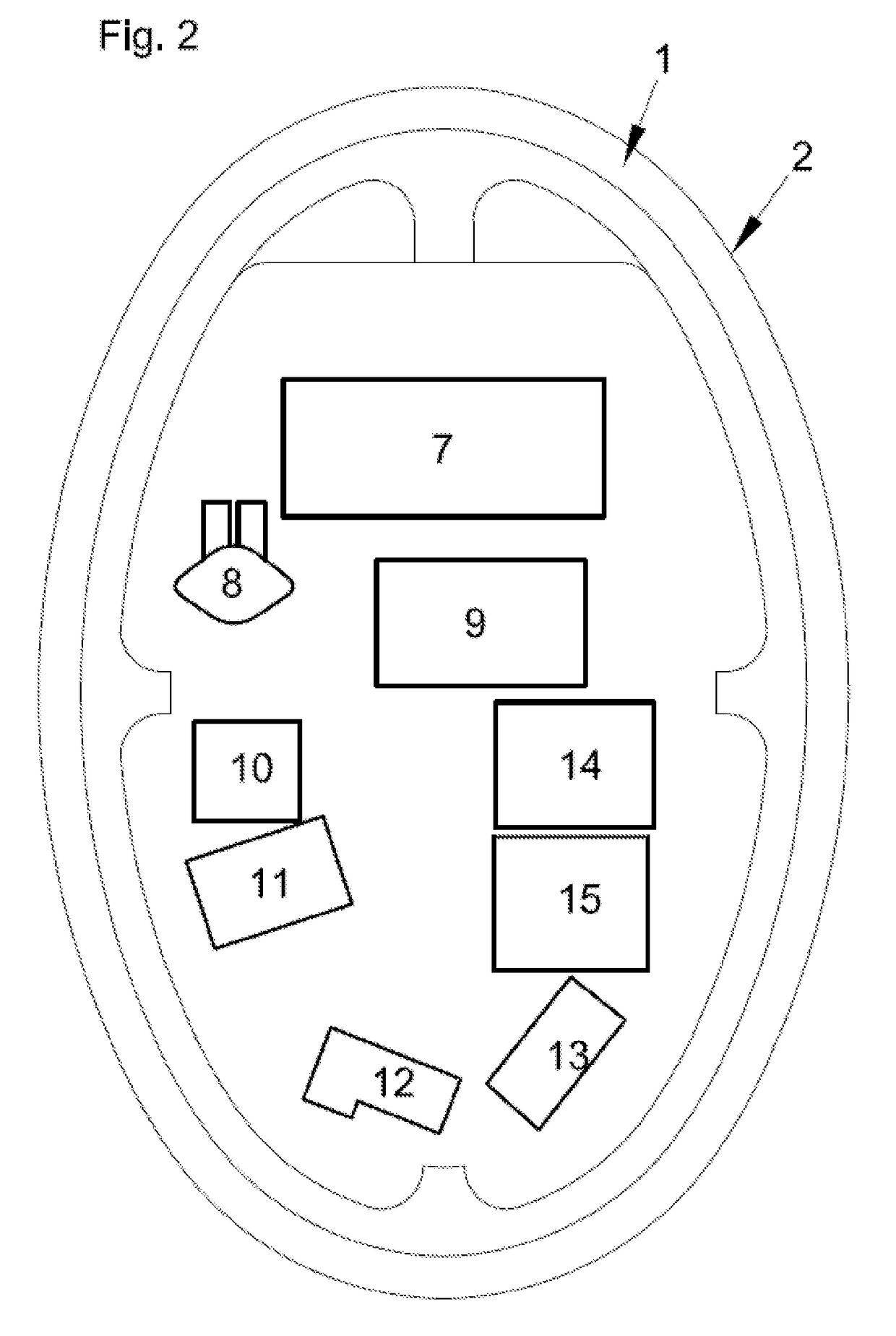

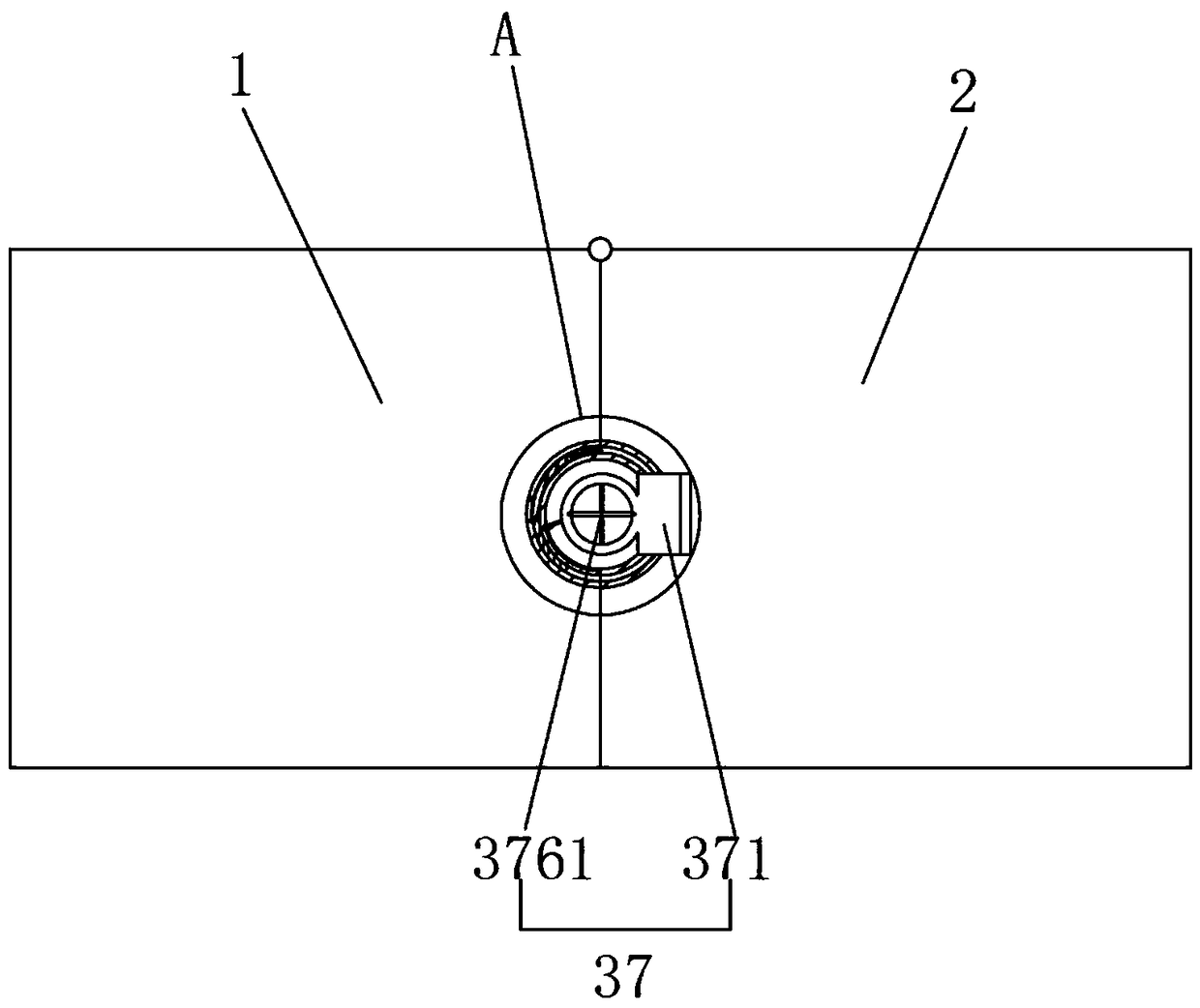

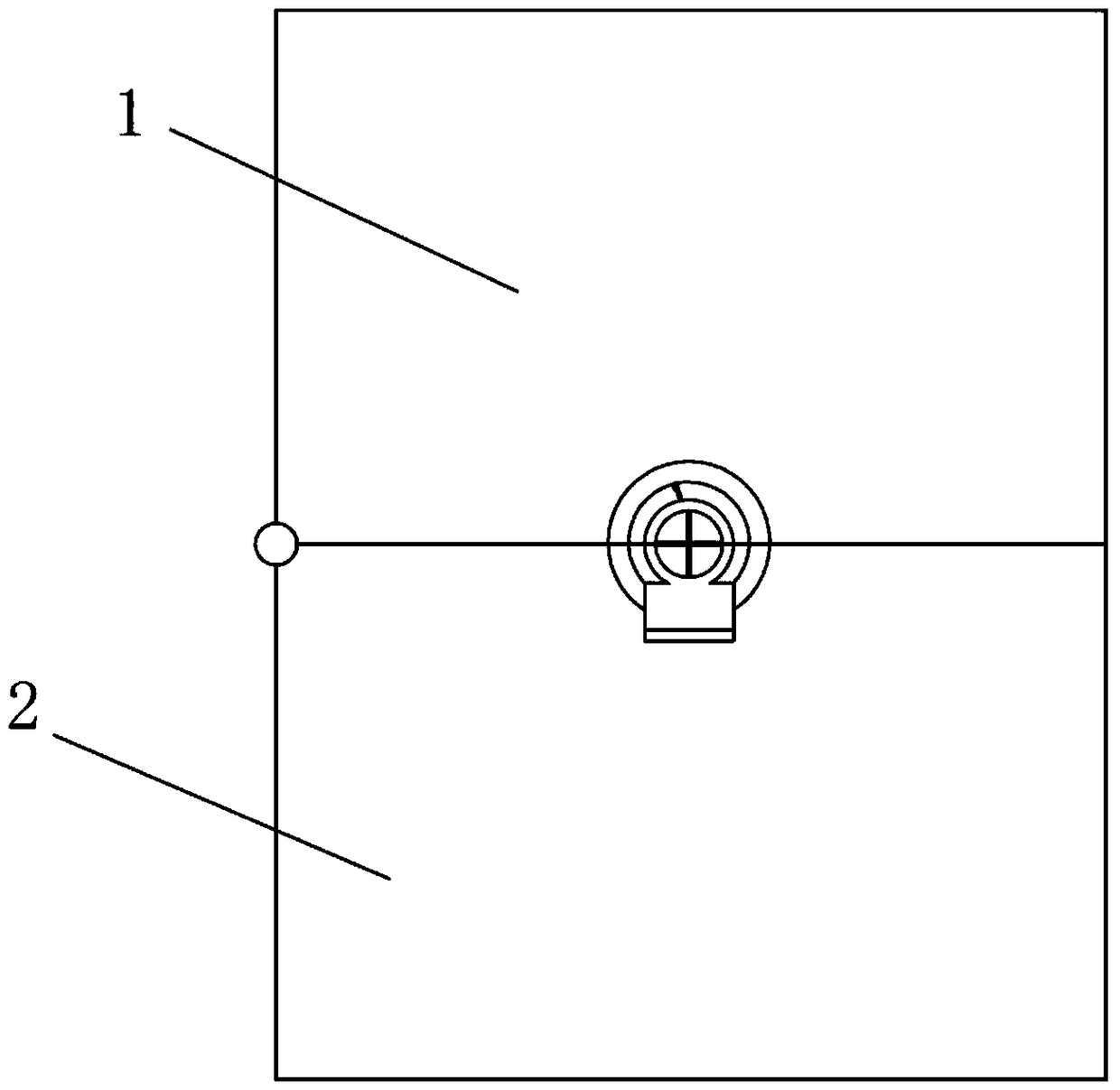

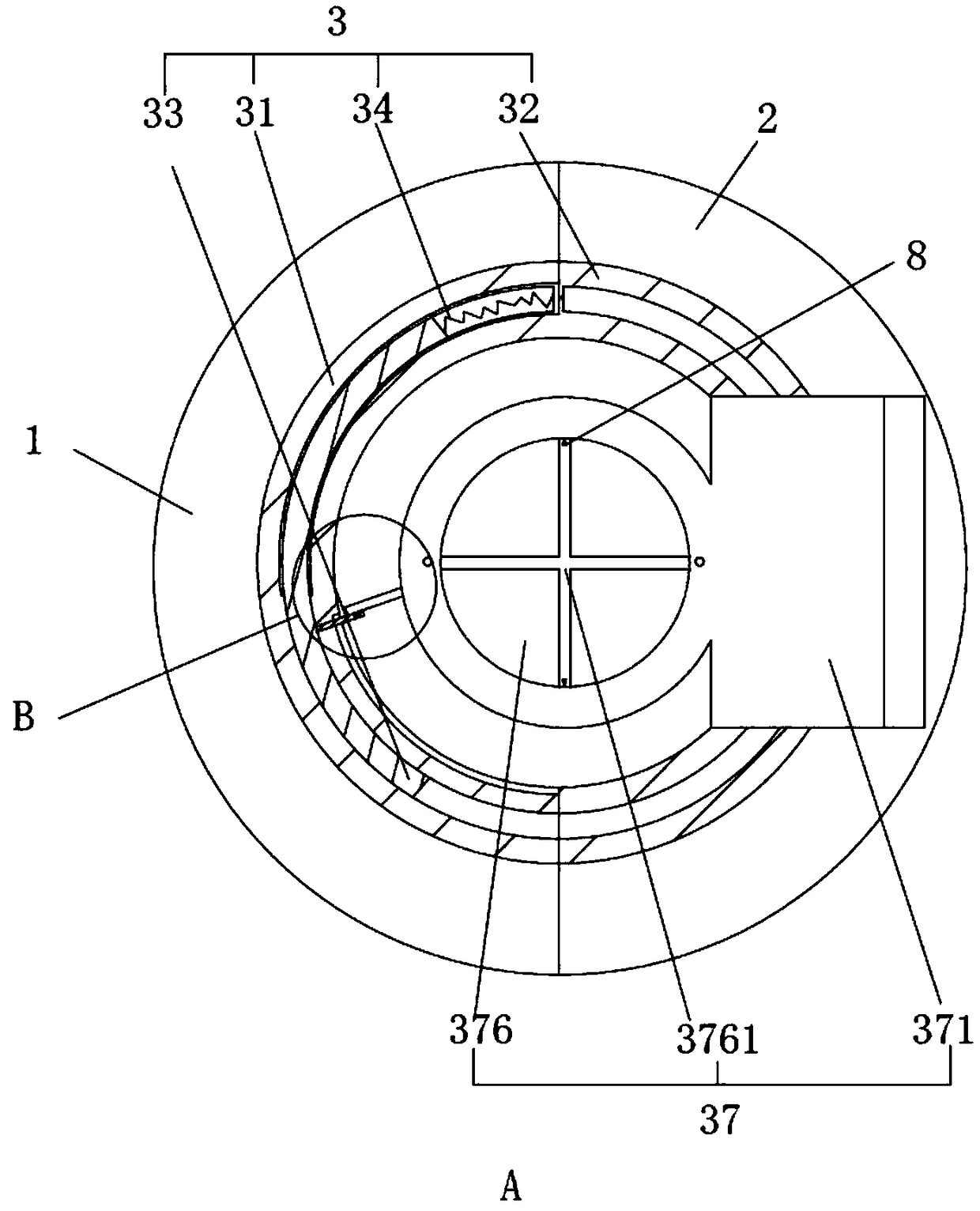

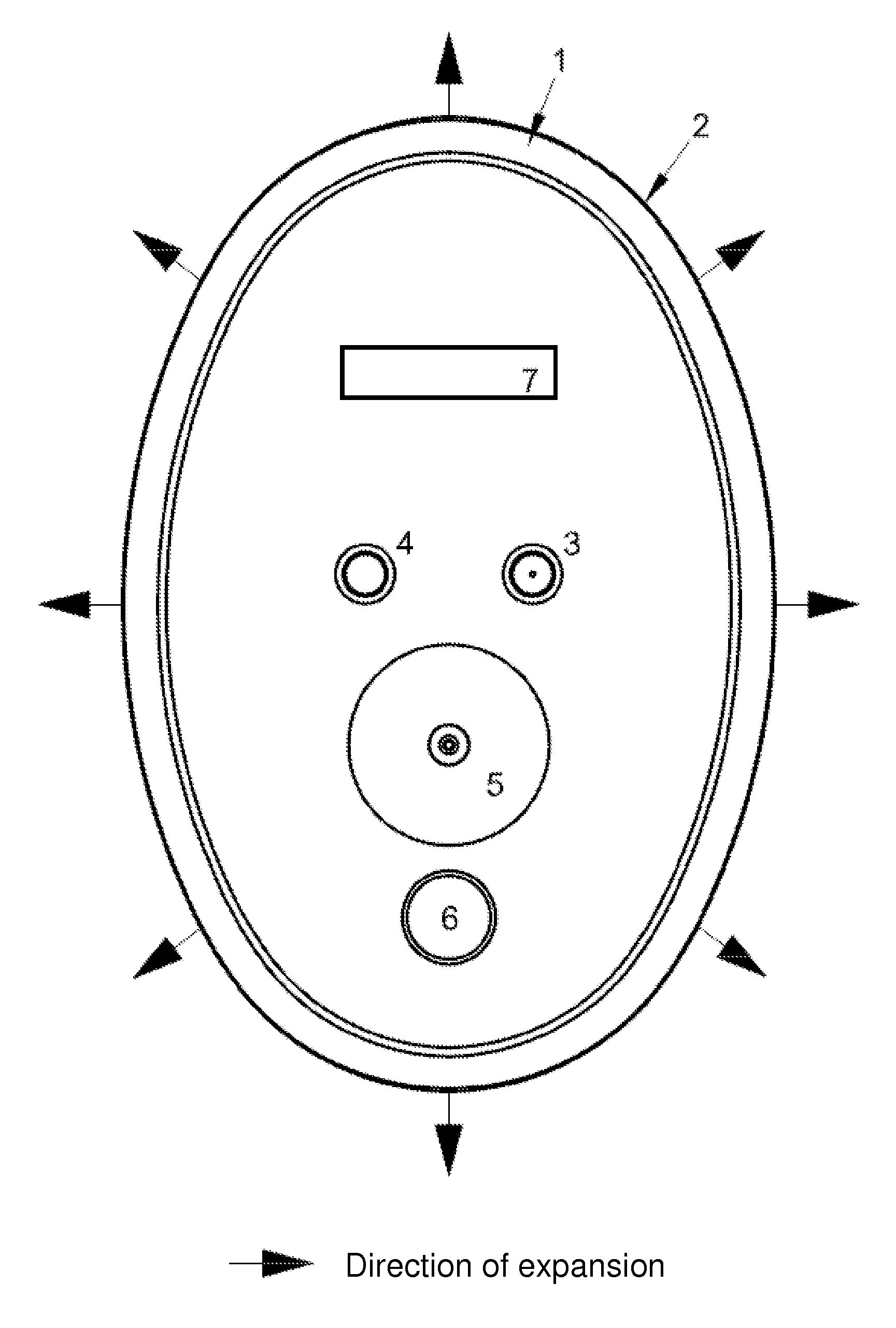

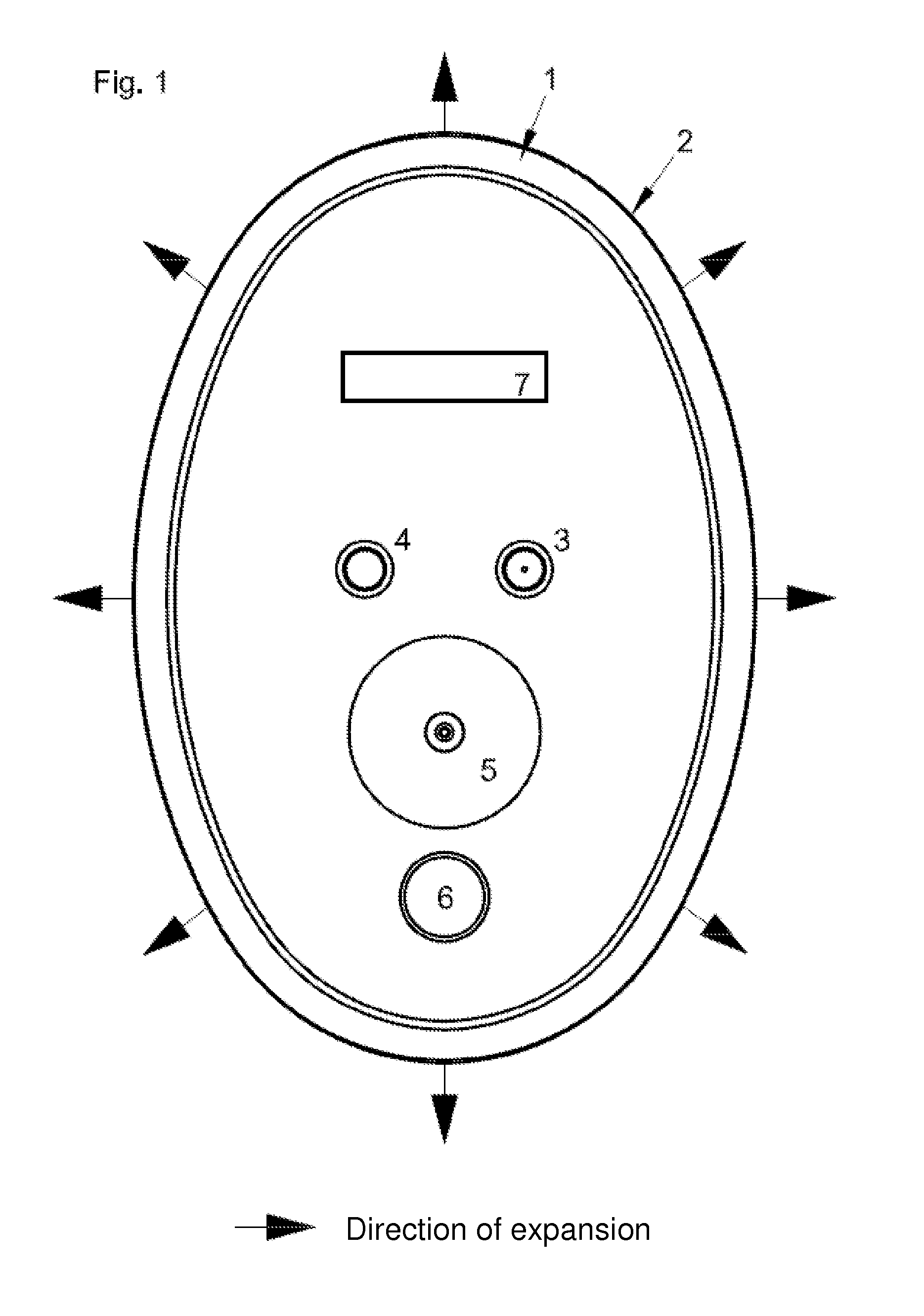

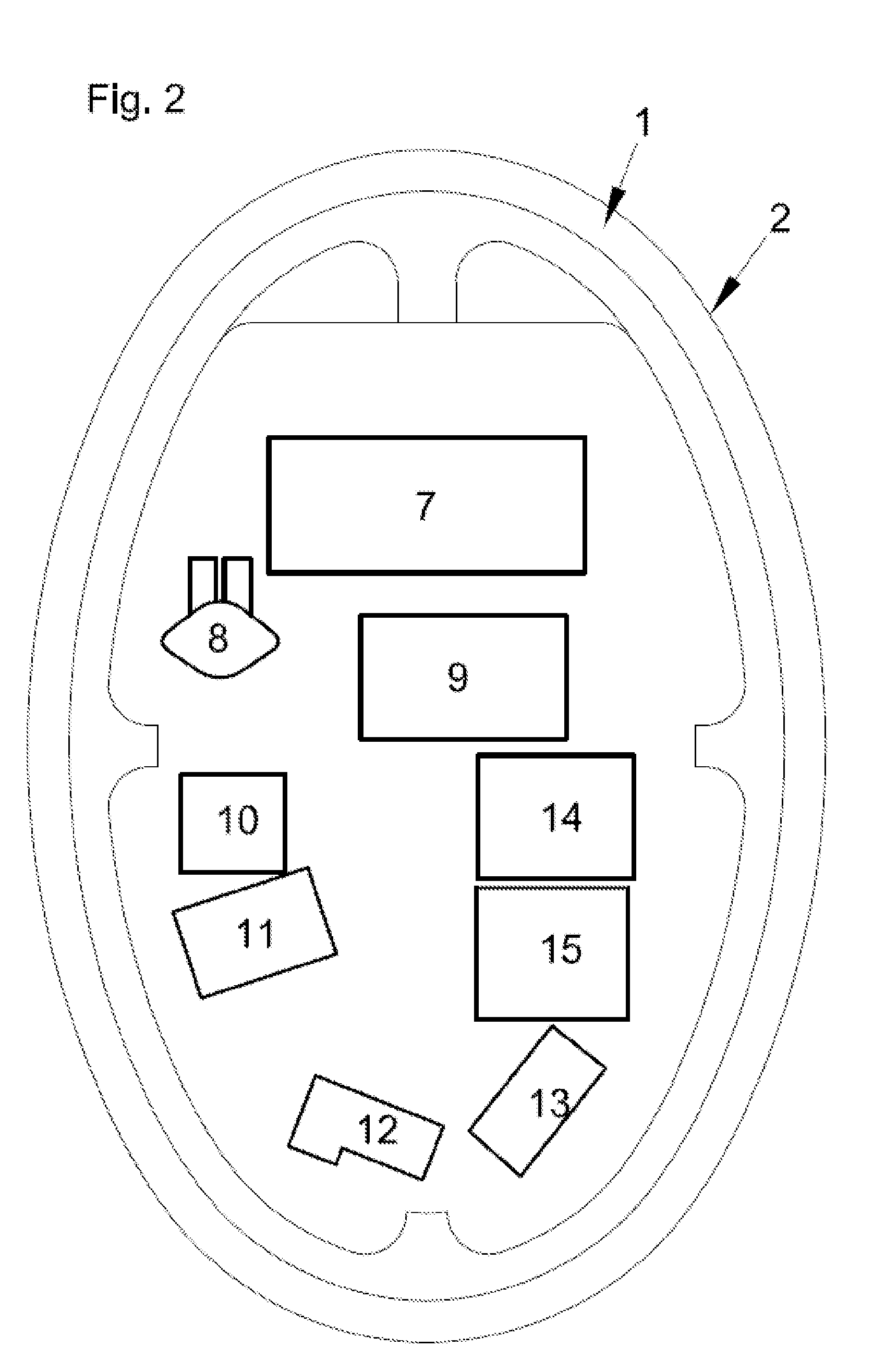

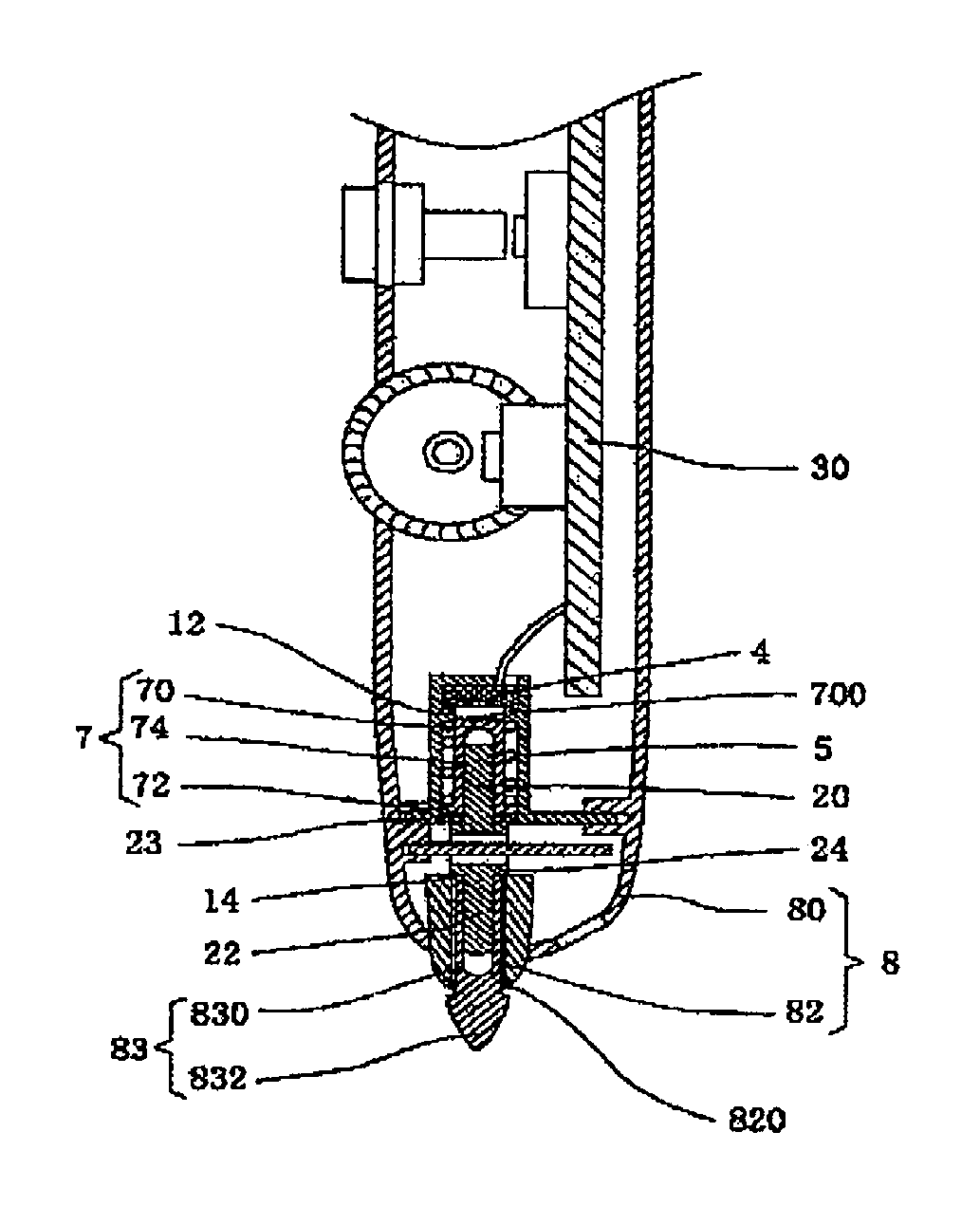

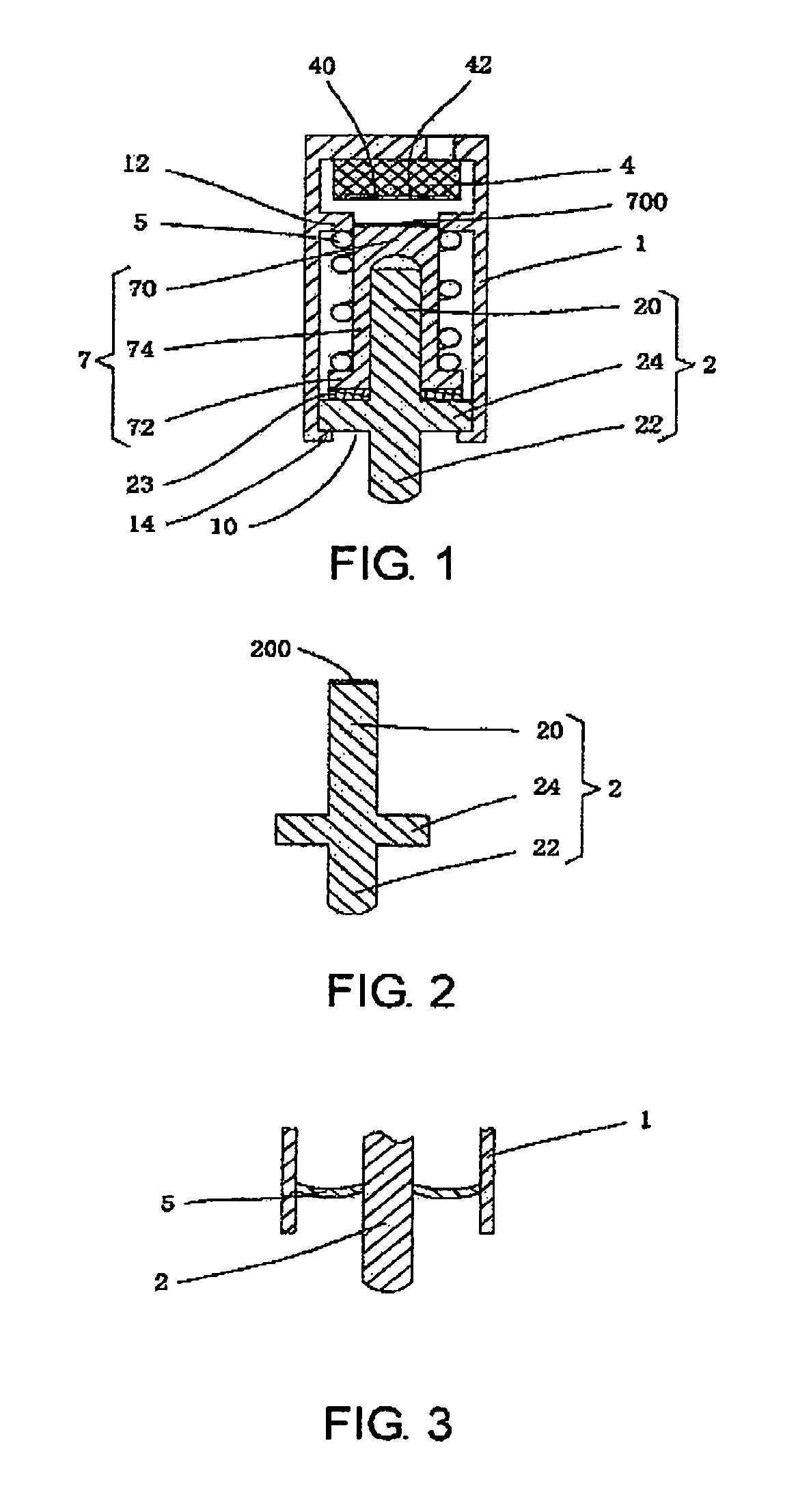

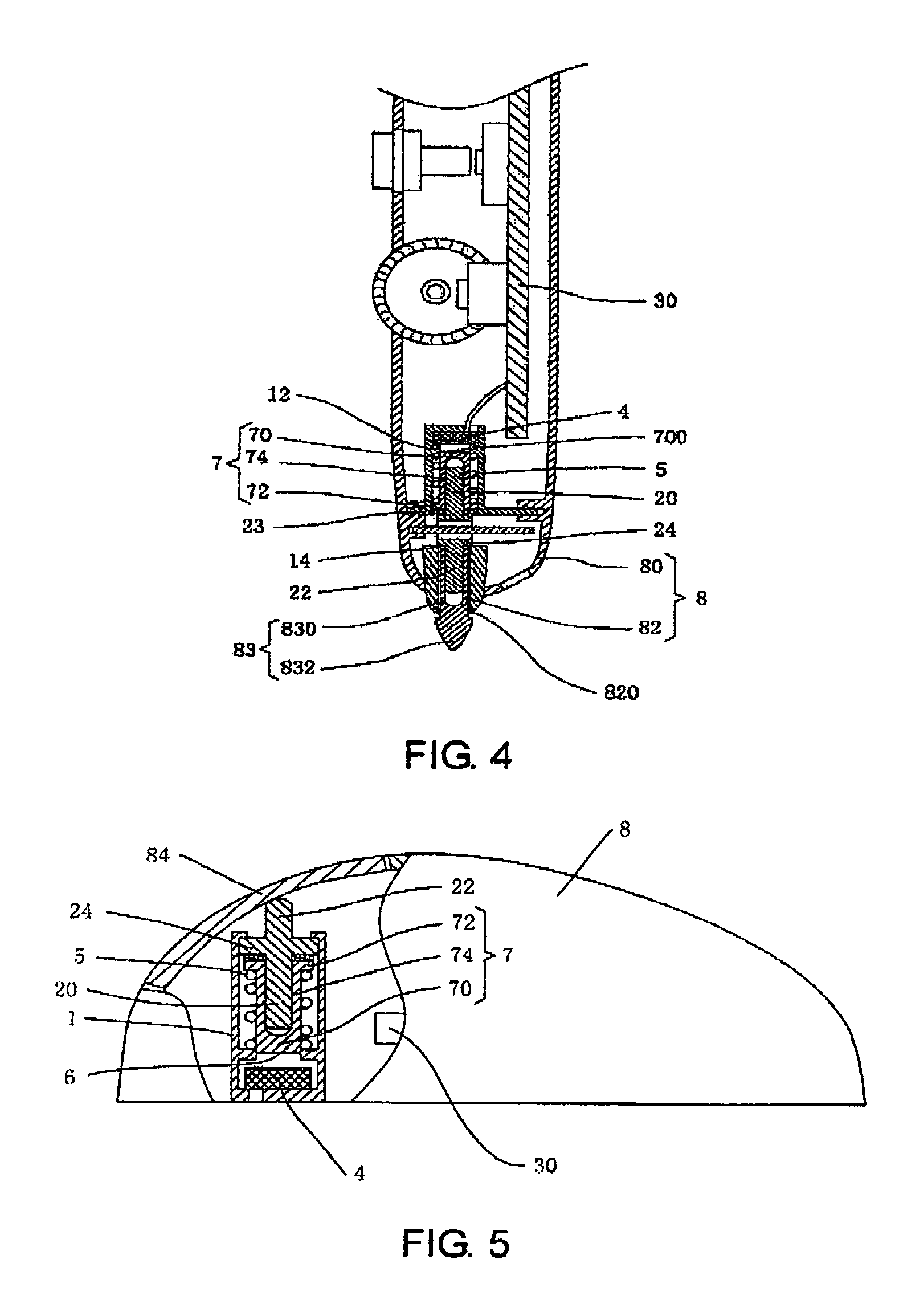

Mouse Pen and Photoelectric Control Switch Thereof

InactiveUS20120206360A1Guaranteed usage periodReduce overall outer diameterCathode-ray tube indicatorsInput/output processes for data processingJoystickEngineering

A mouse pen and a photoelectric control switch thereof are provided, the photoelectric control switch includes a control rod in a shell moving between on-position and off-position, an optical coupling sensor comprising a light emitter and light receiver disposed on an extension line of the control rod, and an elastic element for resetting the control rod. The control rod includes a first end near the optical coupling sensor and equipped with a reflection element, and a second end for driving the control rod towards the optical coupling sensor which protrudes an orifice of the shell; at the on-position, light emitting from the light emitter is received by the light receiver after being reflected by the reflection element, while at the off-position, light cannot be received. The photoelectric control switch implements non-contact on / off controlling with the optical coupling sensor and the control rod, responses sensitively, and has longer lifetime.

Owner:SHENZHEN YIBAO TECH

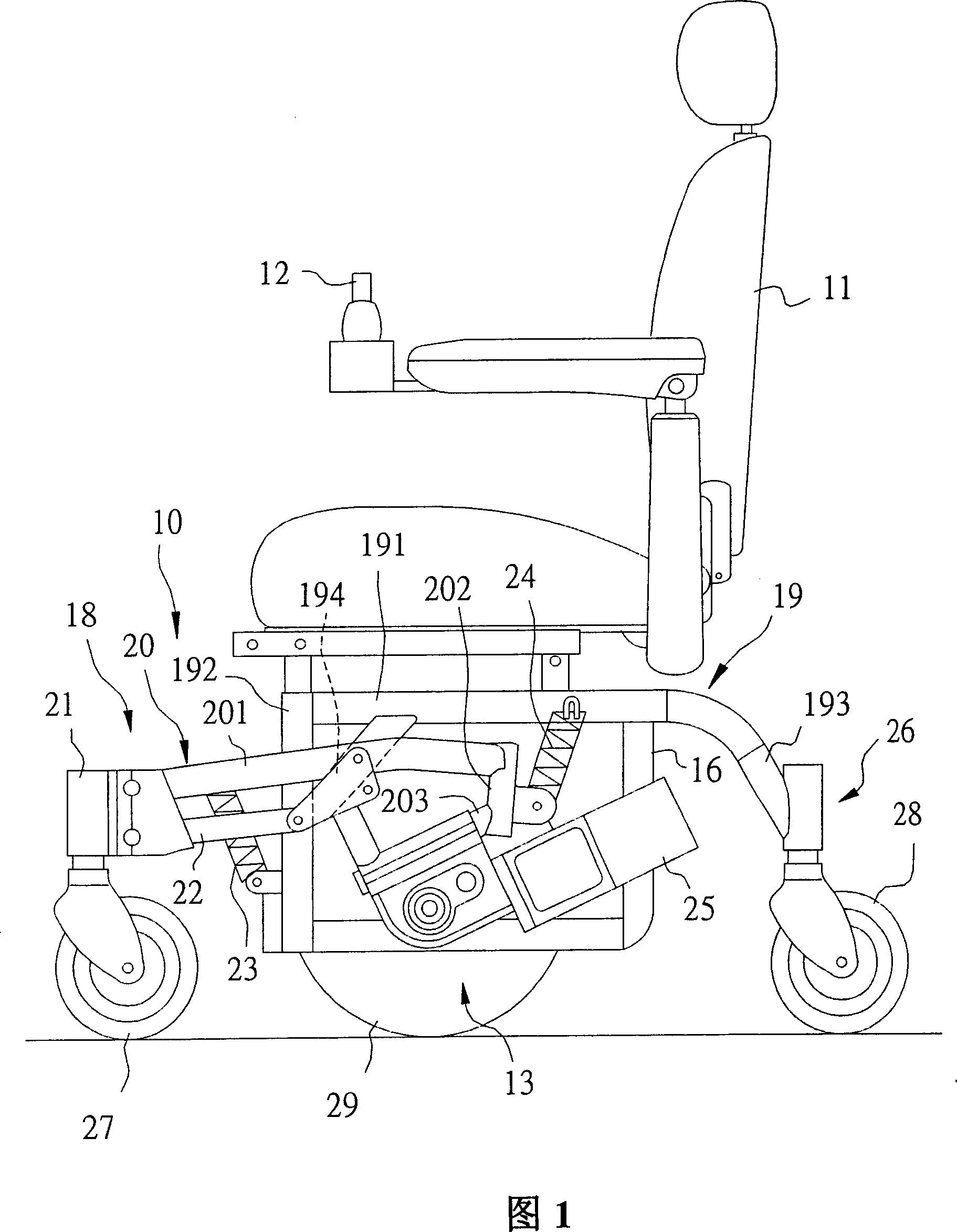

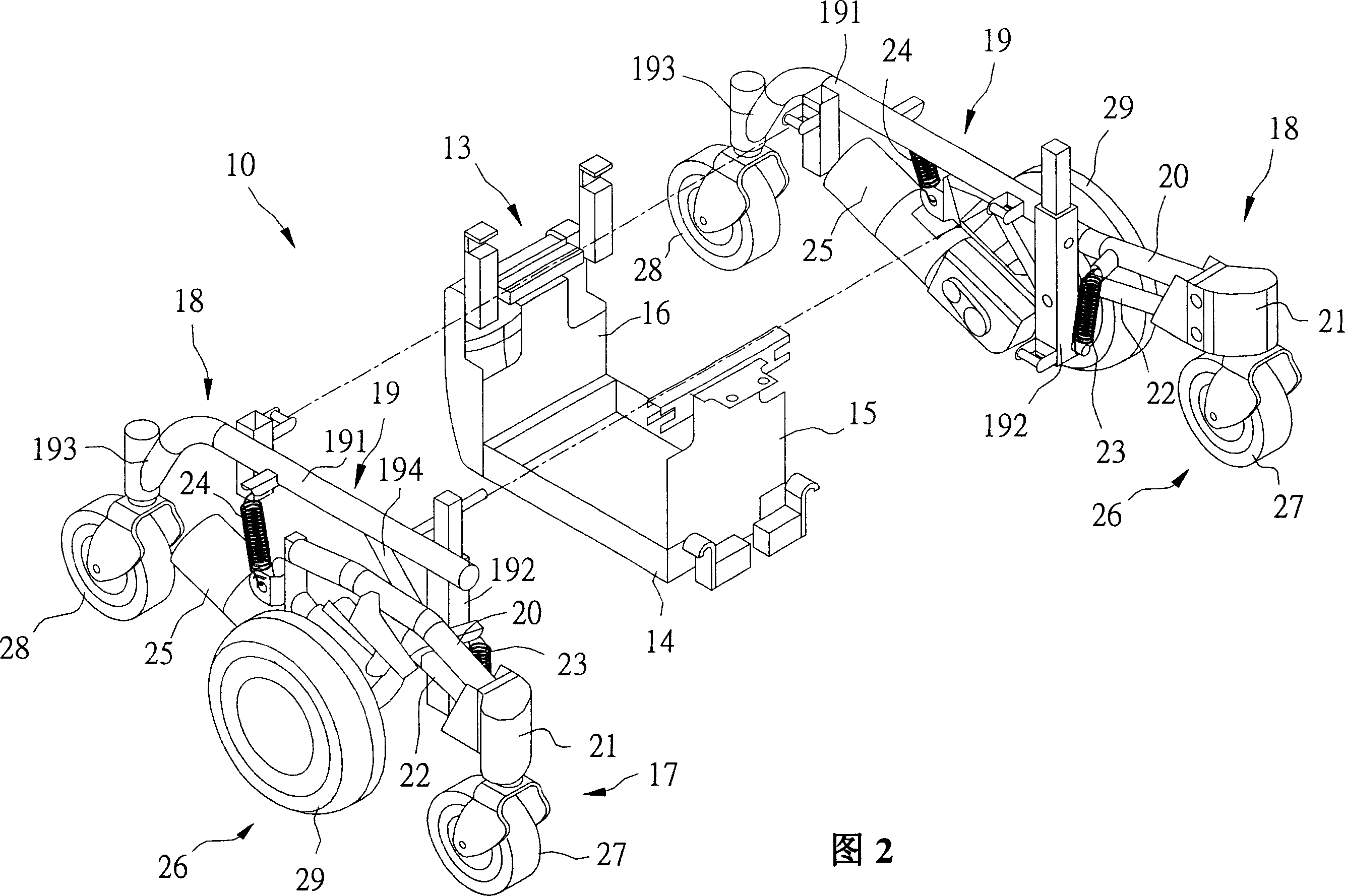

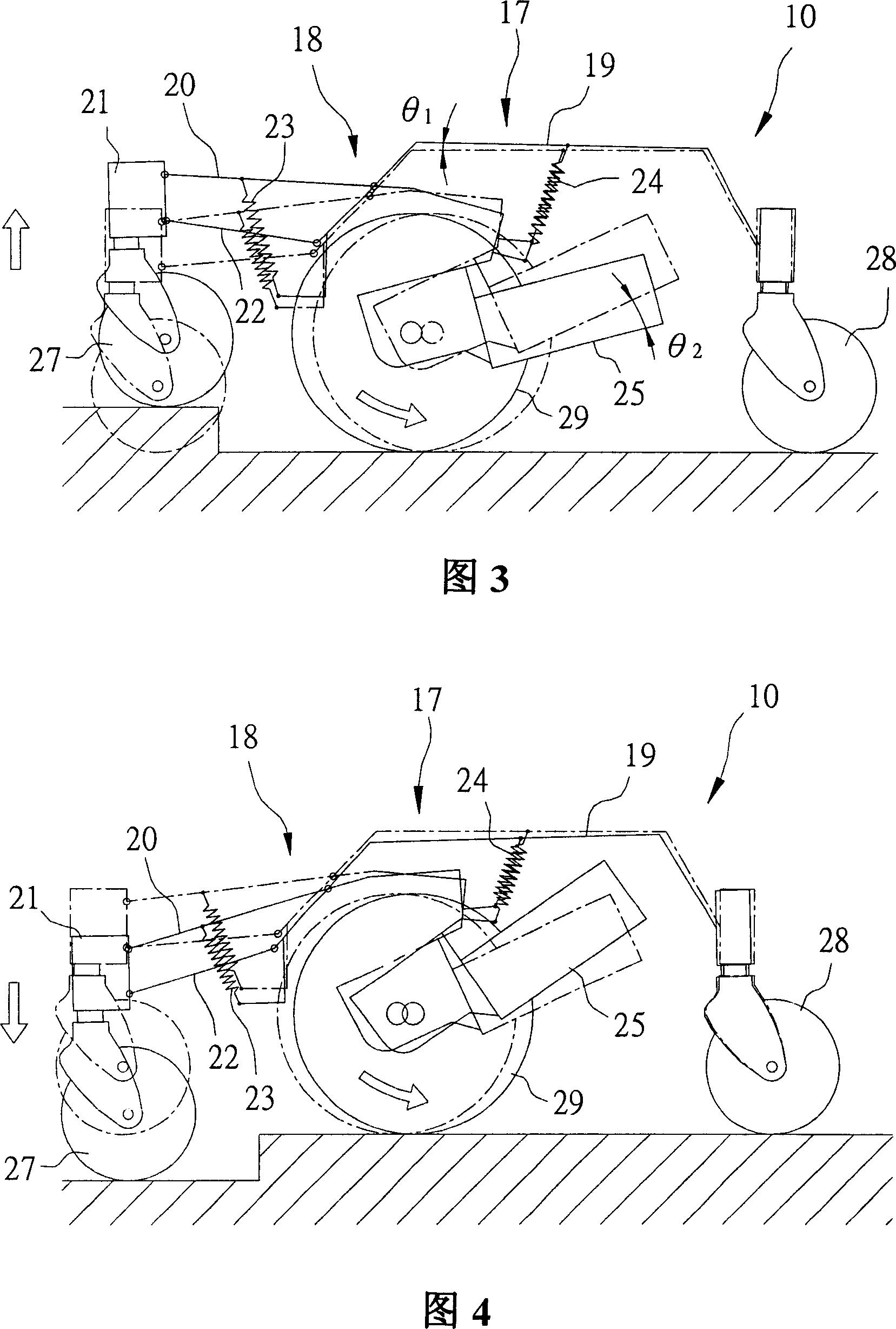

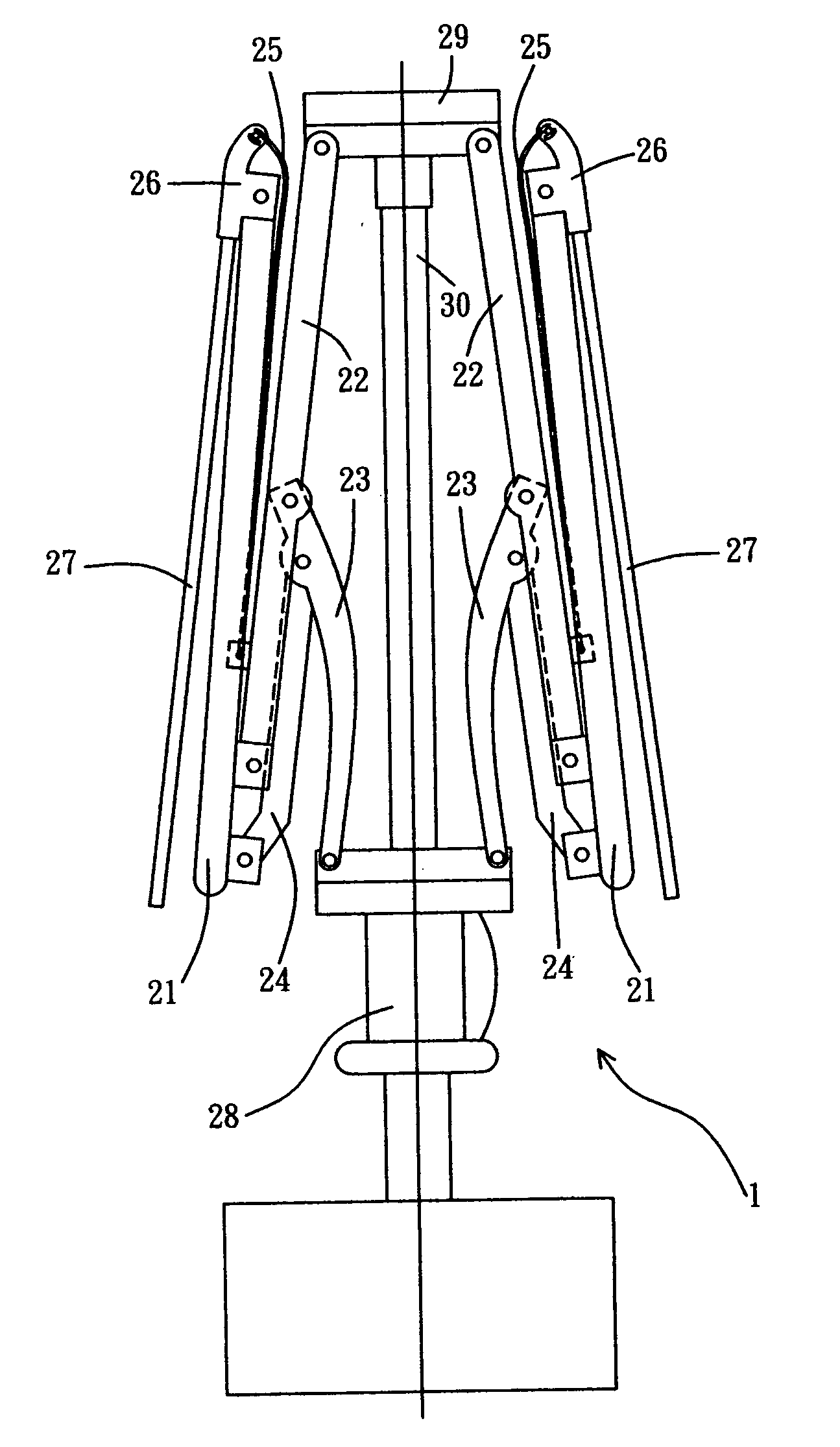

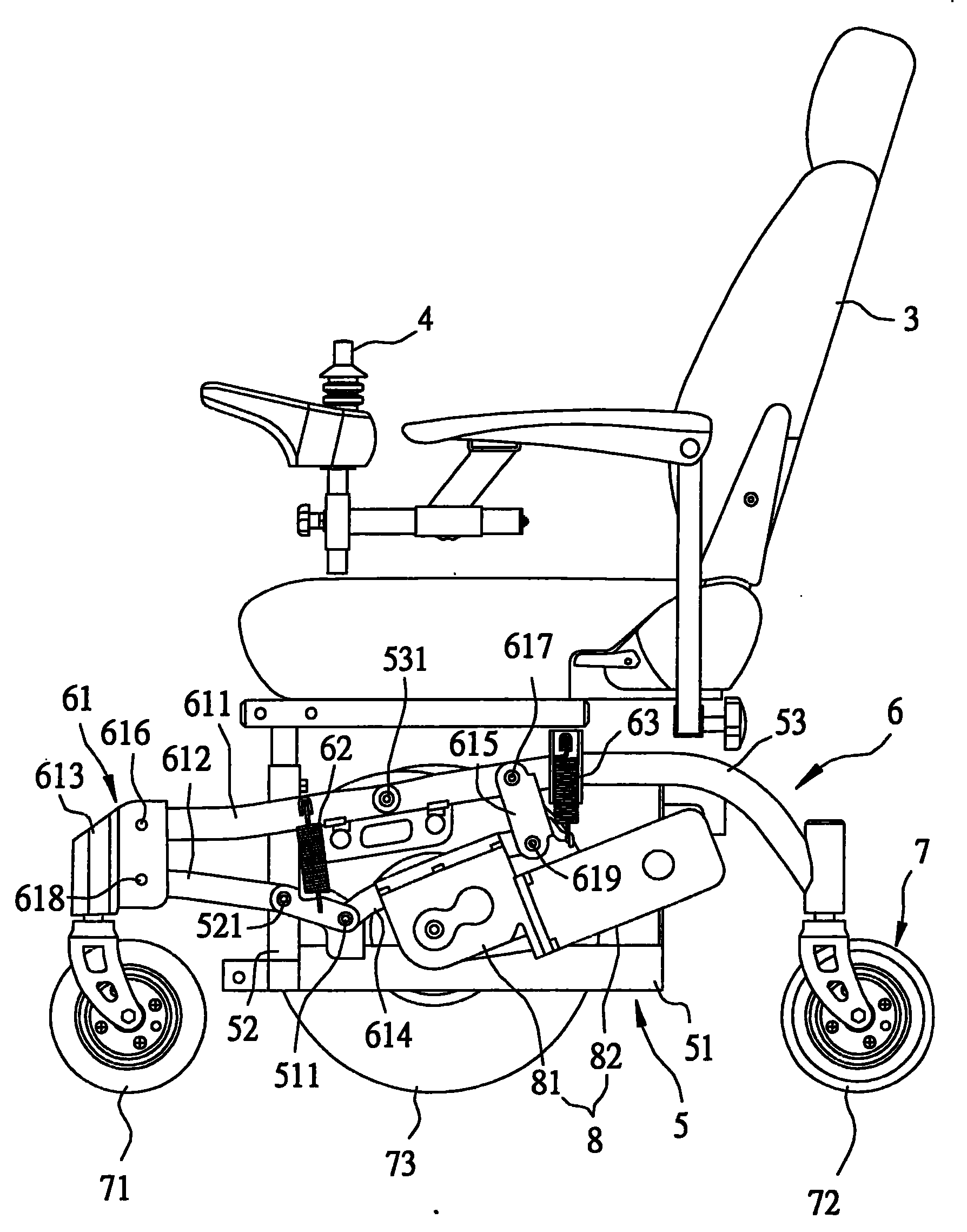

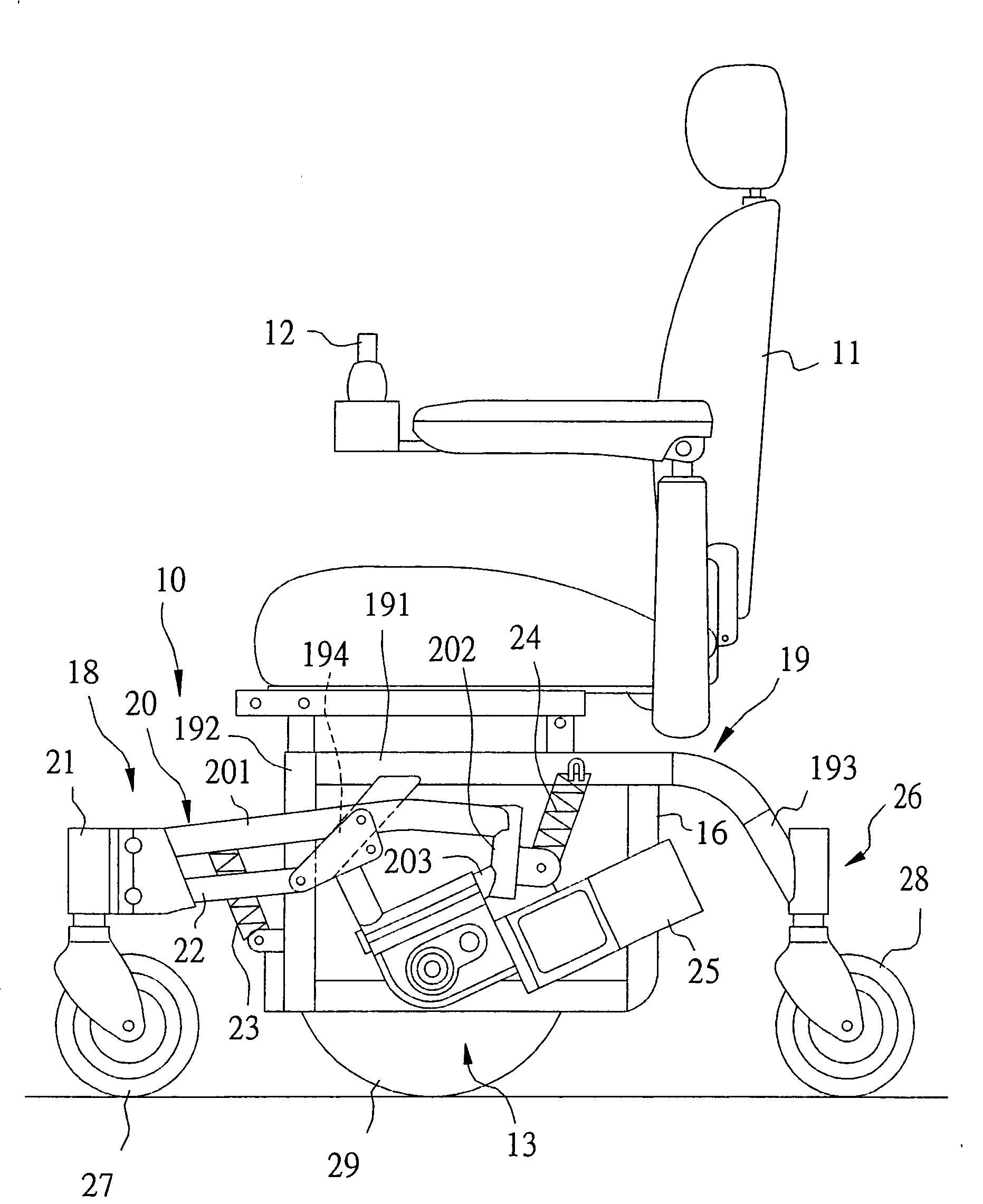

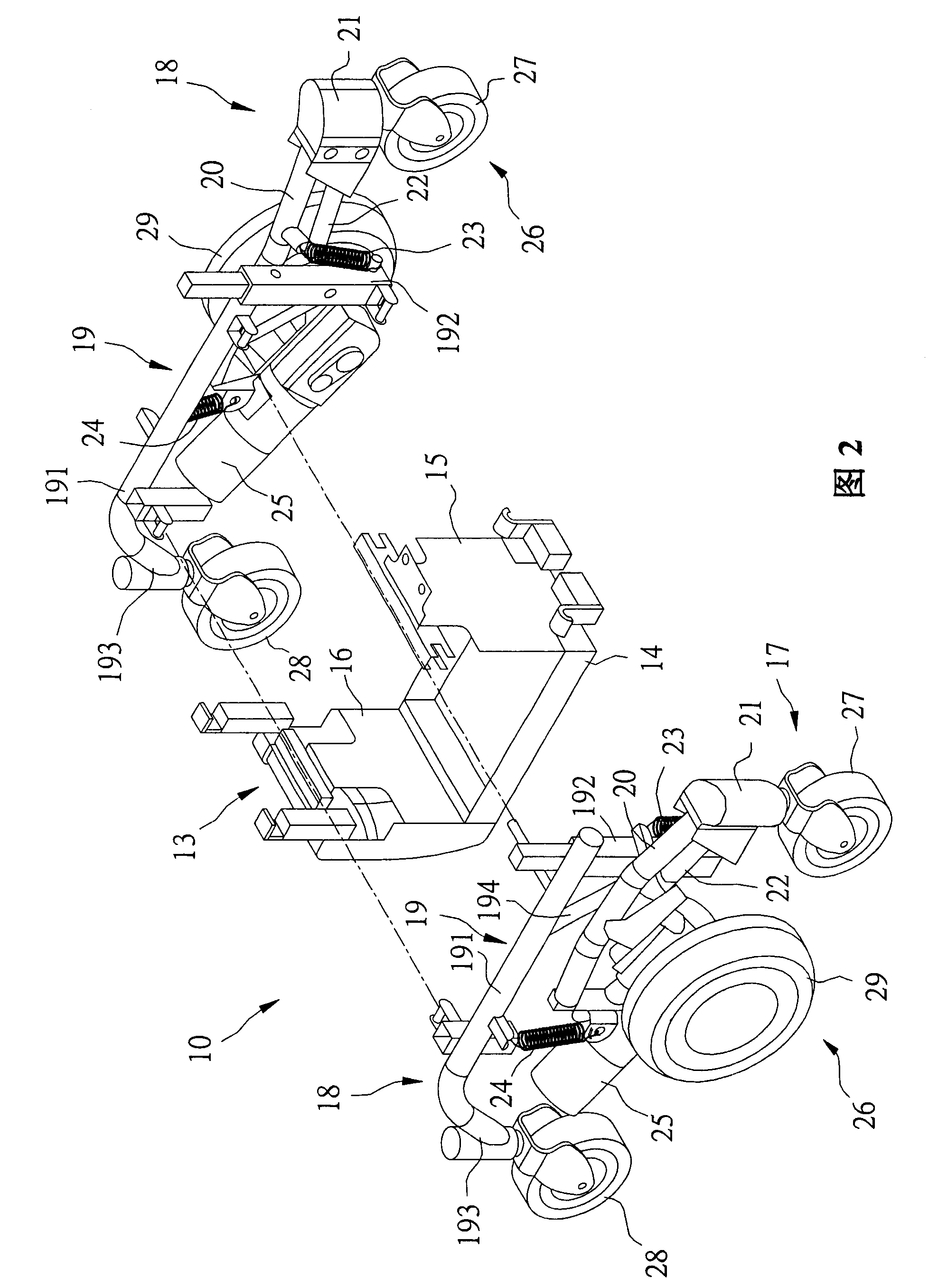

Chassis device for electric wheelchair

A chassis device of an electric wheelchair includes a frame unit, a linking unit, a wheel unit and a power unit. The frame unit is provided with a first arrangement of a bottom border which is provided with a first pin joint point, a second arrangement of a standing post which is provided with a second pin joint point and the second arrangement of the standing post of a third pin joint point. The linking unit is provided with two connecting rod groups, which are respectively arranged at two sides of the frame unit. The first connecting rod group is provided with an upper rocker which is articulated at the third pin joint point and extends forwards and backwards, a lower rocker which is articulated at the second pin joint point and extends forwards, a bottom rod which is articulated at the first pin joint point and extends backwards and a back rod which is articulated with the upper rocker and the bottom rod. The bottom rod and the back rod are used to absorb the oblique angle of the rod, which is caused by the up and down swing to bring comfort to the sitting person.

Owner:KYMCO

Flameproof surface phosphating process and used phosphating solution

The invention relates to the technical field of flameproof surface treatment processes, and in particular relates to a flameproof surface phosphating process for electrical equipment. The process comprises the steps of preparing phosphating slurry: accommodating warm water with a plastic container, sequentially adding basic copper carbonate, nitric acid, phosphoric acid, zinc oxide, hexamethylene tetramine, sodium fluoride and zinc nitrate, and adding the prepared phosphating solution into talc powder to form paste; brushing the prepared phosphating solution slurry on a flameproof surface in a manner that the thickness of the slurry is not less than 2mm; ensuring the retention time of the phosphating solution slurry on the flameproof surface according to the ambient temperature and the following standards, and wiping the phosphating solution slurry on the flameproof surface, thus phosphating the flameproof surface, namely forming a layer of phosphating film on the flameproof surface. The flameproof surface treated through the phosphating process provided by the invention can not be rusted over more than two years, so that the use safety of underground equipment is greatly improved.

Owner:CHANGZHOU LIANLI AUTOMATION TECH

Methods And Compositions for Animal Feed

ActiveUS20160015056A1Improve survival rateUseful lifespanBiocideInorganic phosphorous active ingredientsElement compositionIndividual animal

Owner:CORE INTPROP HLDG

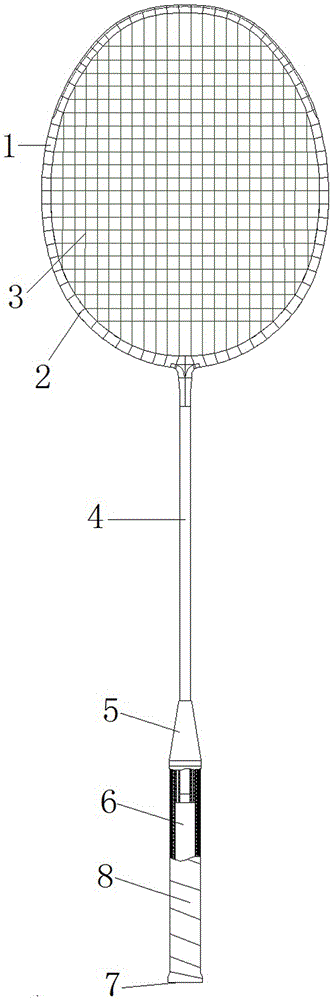

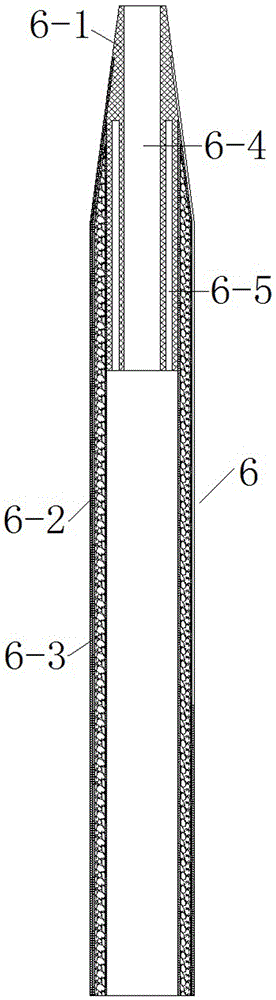

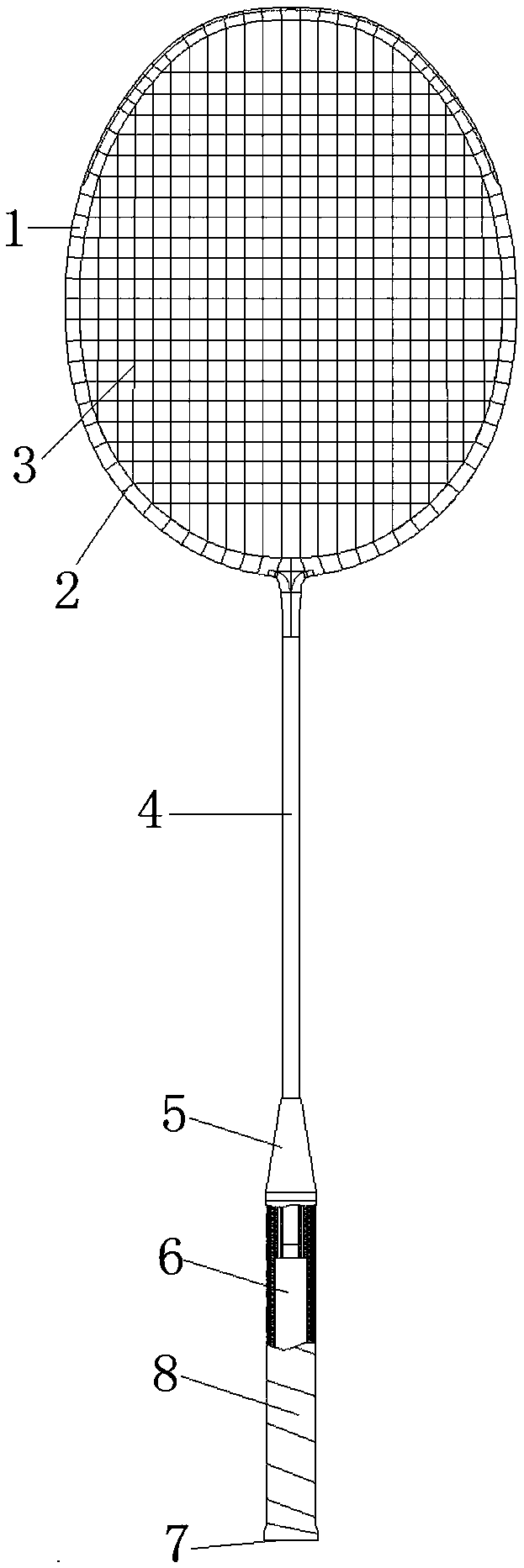

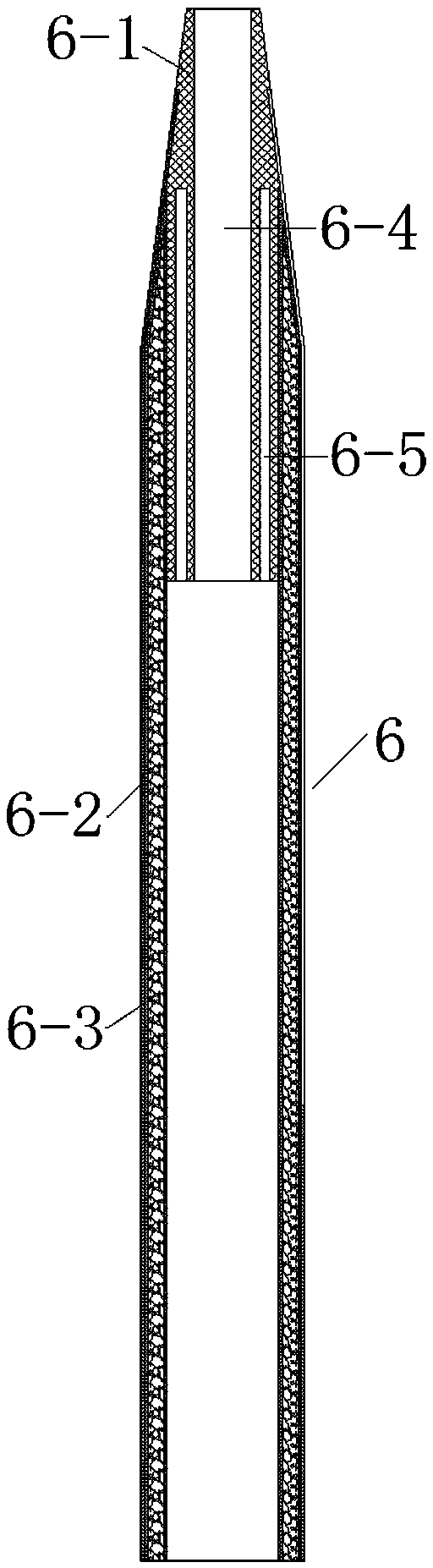

Battledore handle and manufacturing method thereof

The invention relates to a battledore handle and a manufacturing method thereof, belongs to the athletic sports appliance industry, and in particular relates to a battledore handle of a novel structure and a manufacturing method of the battledore handle. The battledore handle comprises a front cone and a carbon fiber handle, wherein a center hole is formed in the middle of the front cone; and grooves are designed in the upper and lower surfaces of the front cone. The manufacturing method comprises the following steps: filling cut PU foam materials in the two sides and grooves of the front cone, coating carbon fiber composite material prepreg cloth coated with resins on the exterior, inserting a front cone positioning pin into the center hole of the front cone so as to complete front cone preforming; and coiling the carbon fiber handle by using the cut carbon fiber prepreg cloth, and coating the front cone and the carbon fiber handle layer by layer by using the carbon fiber prepreg cloth, so that the front cone and the carbon fiber handle are tightly connected together, and an integrated battledore handle is formed. According to the application of the manufactured battledore handle disclosed by the invention on the battledore, the shock absorption performance of the front cone part of the battledore handle is increased, the strength of the battledore handle is stable, the precision is high, the stability of the battledore frame is effectively improved after ball hitting, the shock reduction performance of the battledore is improved, and sports injuries are reduced.

Owner:SUQIAN ADK COMPOSITES

Methods and compositions for animal feed

ActiveUS9549565B2Improve survival rateUseful lifespanInorganic phosphorous active ingredientsInanimate material medical ingredientsElement compositionAnimal feed

The present invention is directed to methods and compositions that are useful in producing, feeding and growing animals. Compositions of the present invention comprise an extracted mineral element composition as disclosed herein. Animal lifespan and production is improved when provided with compositions comprising an extracted mineral element composition.

Owner:CORE INTPROP HLDG

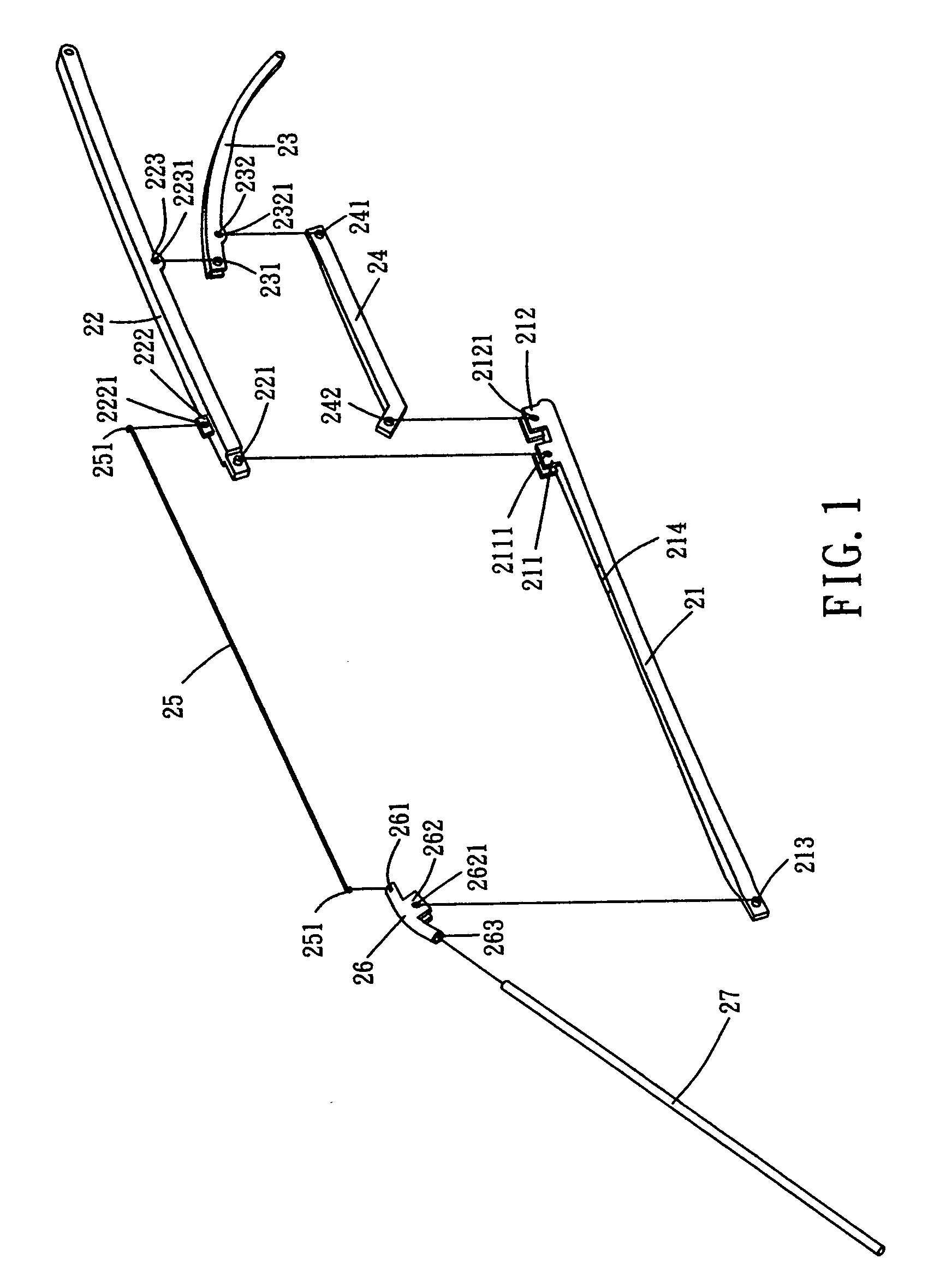

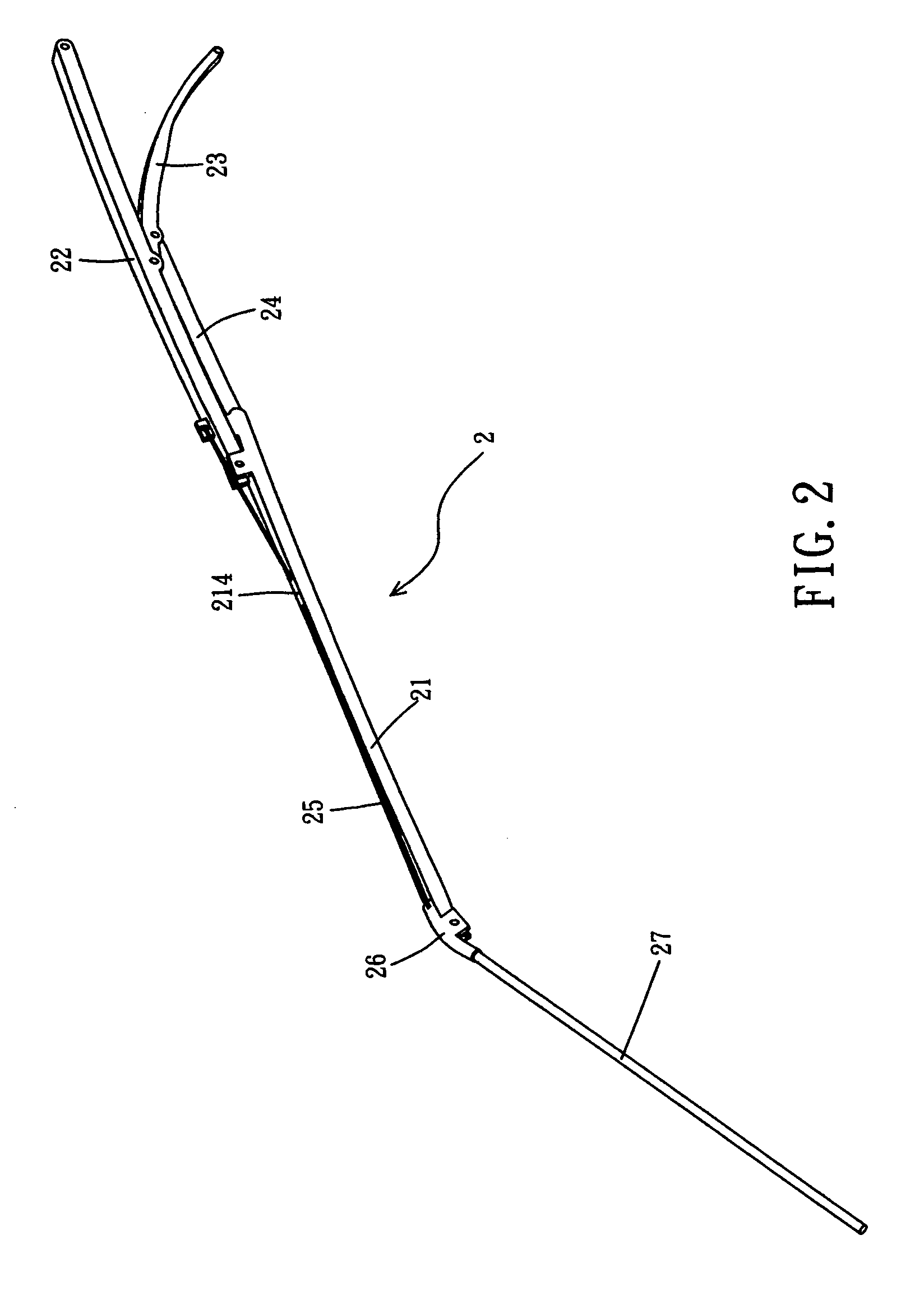

Umbrella frame

InactiveUS20050161068A1Easily brokenGuaranteed usage periodWalking sticksUmbrellasEngineeringElastic rods

An umbrella frame has a lower runner, a main shaft, an upper runner, and a plurality of stretching frames. Each stretching frame has a stretcher, a connection plate, an elastic rod, a connector, a distal rod, a long rib, and a short rib. The connection plate has a first end protrusion and a second end proton. The connector has an end notch, an end hole, and a lower protruded block having a circular hole. The long rib has an end protruded block inserted in the circular hole, an inner protruded bar having a first through aperture, and an outer protruded bar having a second through aperture. The elastic rod is inserted through a spacing defined by the upper pressing bar and the long rib The short rib has a distal protruded block, an upper protruded bar having a round aperture, and a lower lobe having a circular aperture. The elastic rod has two end hooks. The elastic rod is hooked in the end notch and the round aperture. The distal protruded block is inserted in the first through aperture. The second end protrusion is inserted in the second through aperture. The distal protrusion is inserted in the circular aperture.

Owner:LI MING GUNG

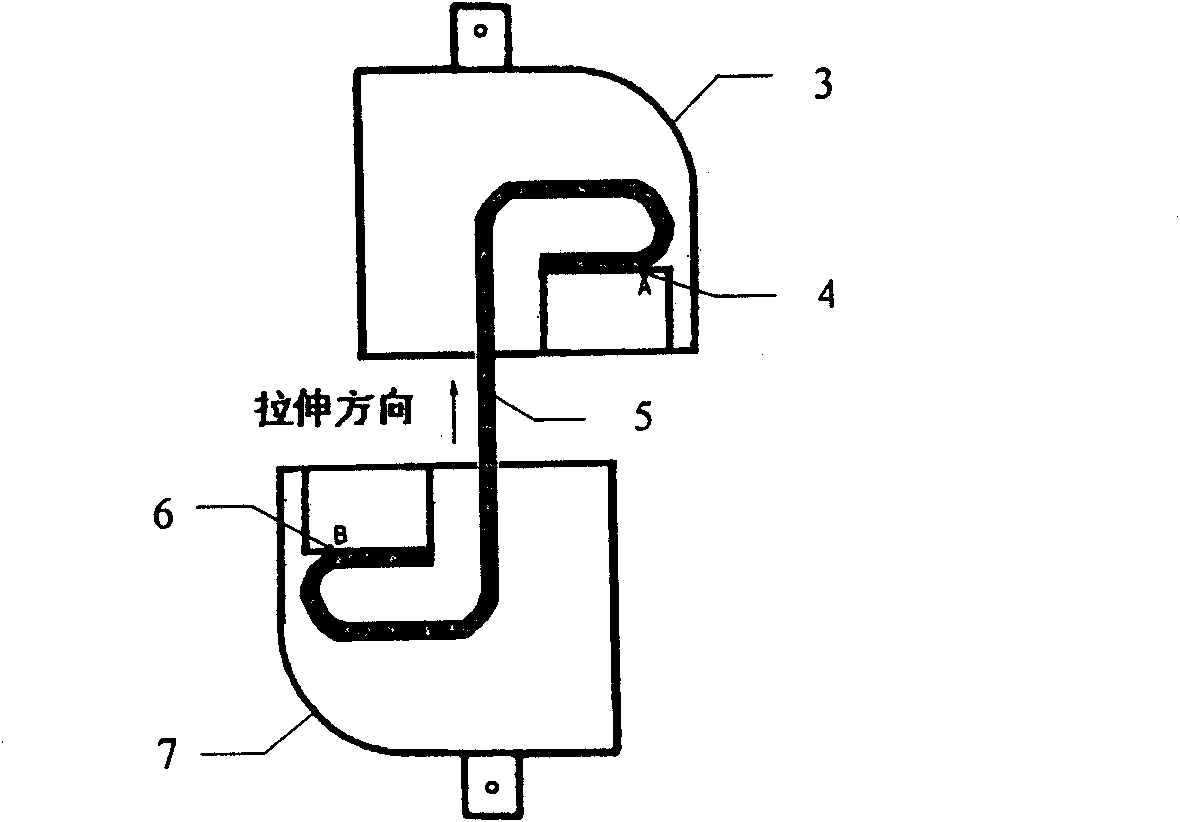

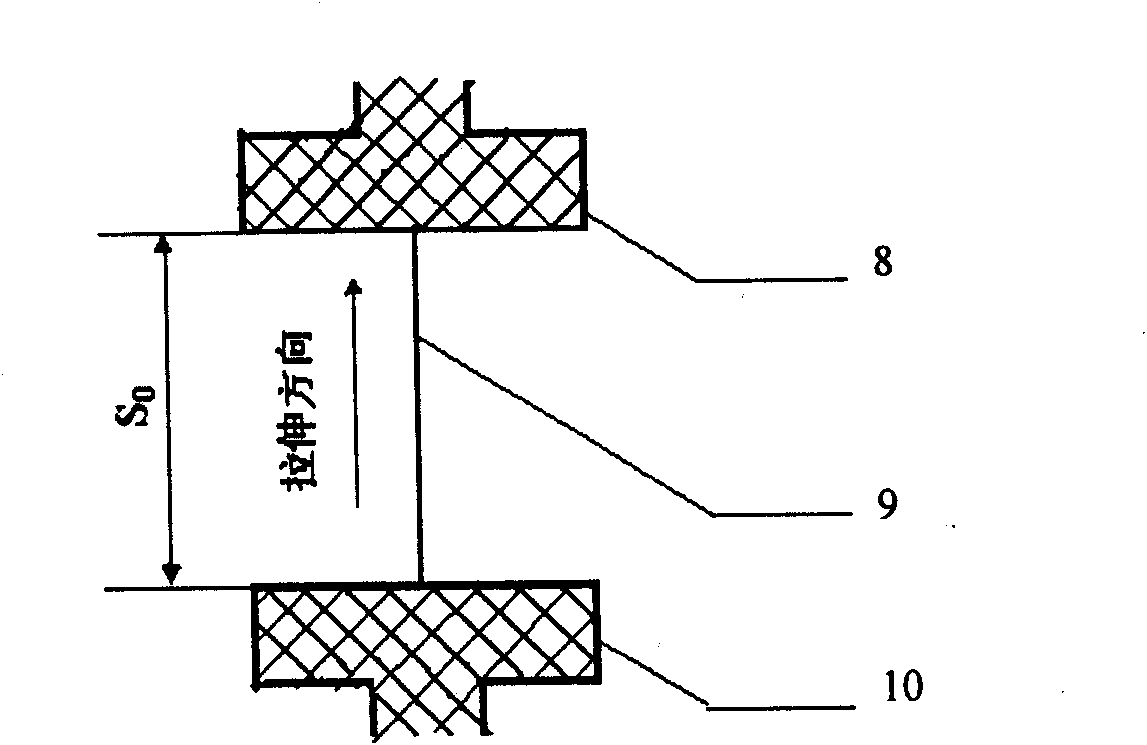

Geometrical structure of trolling nylon braided line and method for measuring mechanical property thereof

InactiveCN101539462AEnsure safetyEnsure the strength of the fishing tackleForce measurementMaterial strength using tensile/compressive forcesEngineeringCoefficient of variation

The invention provides a geometrical structure of a trolling nylon braided line and a method for measuring the mechanical property thereof, and relates to the measurement of the trolling nylon braided line. The method comprises sampling, conditioning balance, geometrical structure and mechanical property test, and is characterized in that: the samples are selected from more than 6 cm away from the tail end of the line; the dry-state sample undergoes the conditioning balance for 5h at a temperature of between 16 and 20 DEG C and a humidity of between 57 and 63 percent, and the wet-state sample is soaked for 5h at a water temperature of between 16 and 20 DEG C; the nylon braided line sample is arranged on upper and lower pneumatic ring clamps of a strength tester, and stretched until broken under conditions of the test distance of 1.20 m and the stretching speed of 120 mm / min; the nylon single filament is arranged on upper and lower pneumatic flat-opening clamps, and stretched until broken under conditions of the test distance of 270 mm and the average broken time of 16 to 20s; and in the test, the effective measurement time is 30, and the average value, coefficient of mean deviation and coefficient of variation are worked out. The geometrical structure and the method are used for measuring the mechanical property of the geometrical structure of the trolling nylon braided line.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

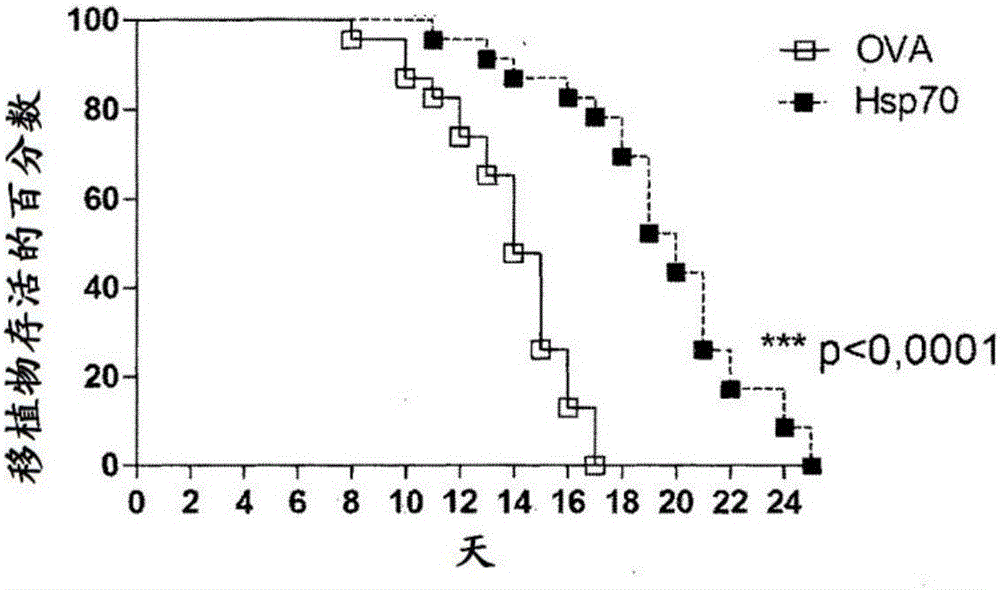

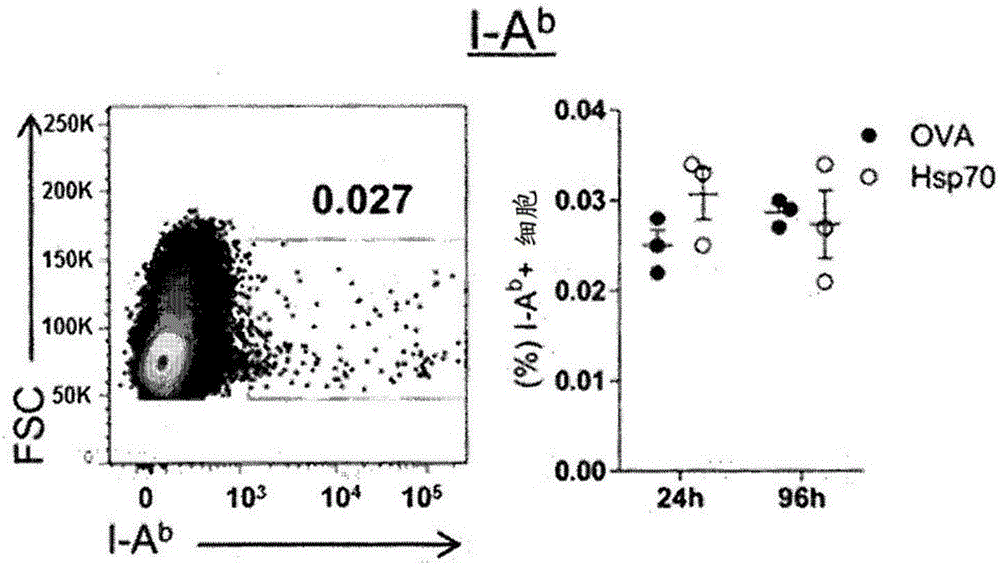

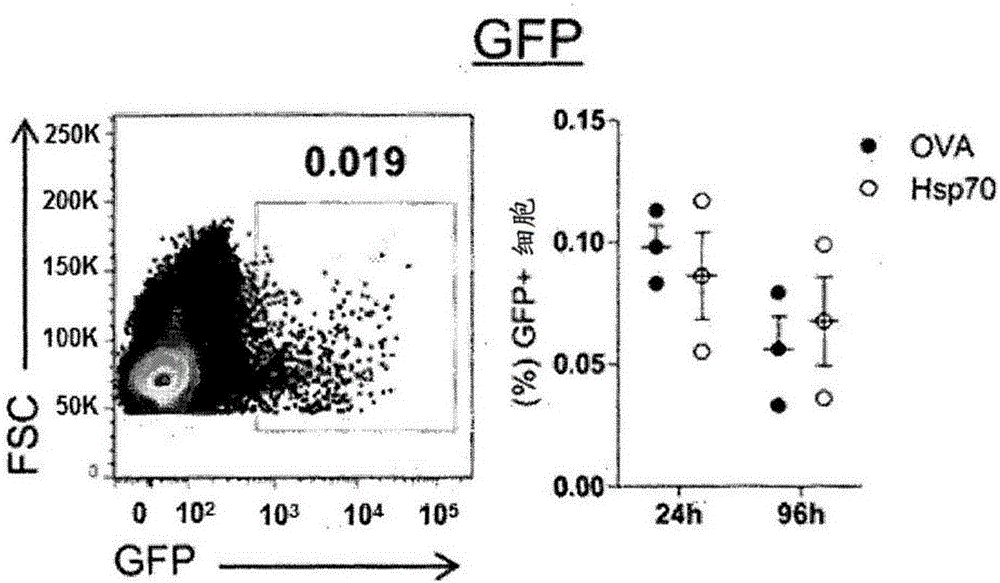

Composition and method for ex vivo immunomodulation and/or preservation of organs, methods and use

InactiveCN105939725AGuaranteed usage periodExtended lifespan in vivoPeptide/protein ingredientsDead animal preservationRegulatory T cellHsp70

The present invention provides a composition for modulating MARCH-I, MHC II and / or CD86 in the cells of an ex vivo organ, that is to say an organ taken from a donor for subsequent transplantation in a recipient. In one embodiment, the composition comprises one or more organ preservation solutions in combination with an Hsp. In another embodiment, the composition of the invention comprises Hsp70 and / or one or more synthetic Hsp70-derived peptides. The composition of the invention provides preservation while at the same time reducing rejection of an organ, thus offering many advantages and solving various relevant technical problems: not only preserving the useful life of the organ but also initiating a process in the organ which inhibits acute rejection; lengthening the useful life of the organ in vivo; having local immunomodulating effects in the recipient; having an indirect impact on the quality of life of the transplant recipient by necessitating fewer immunossuppressive medications; inducing the activity of regulatory T cells (which are acknowledged to be immunosuppressors), reducing the expression of MHC molecules in the graft, reducing alloreactive expression in the recipient's lymph nodes, and lengthening the survival of the graft in the recipient.

Owner:巴西教育和援助联盟

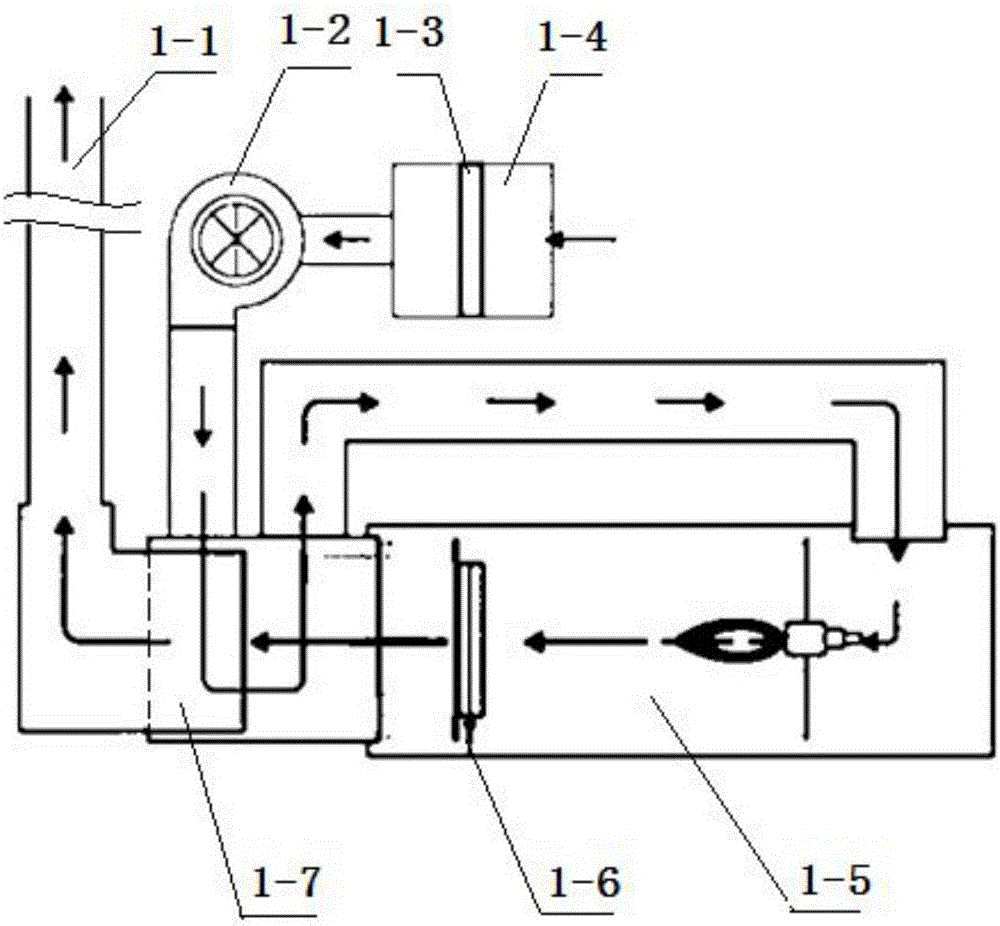

Catalytic combustion device

InactiveCN106322408AGuaranteed usage periodGuaranteed cleanlinessIncinerator apparatusCombustorFlue gas

The invention relates to a catalytic combustion device. The catalytic combustion device comprises a combustor, a heat exchanger, an exhaust gas filter, a fan and a chimney, wherein the exhaust gas filter is connected to an air inlet of the fan, an air outlet of the fan is connected to a gas inlet of the heat exchanger, a gas outlet of the heat exchanger is connected to a gas inlet of the combustor through a flue, a gas outlet of the combustor is connected to the chimney through the heat exchanger, flue gas from the combustor is connected to the chimney through a pipeline, the connecting pipeline passes through the heat exchanger, and a catalytic bed is mounted in the combustor. According to the catalytic combustion device provided by the invention, an exhaust gas filter sheet frame is mounted at the inlet of the exhaust gas filter. The exhaust gas filter sheet frame can fully filter liquid drops in gas and entrained solid small particles to guarantee that gas passing through an ionization chamber does not contain any liquids or particle dust, so that the degree of purification of gas is guaranteed and the service life of a purifier is guaranteed, too.

Owner:TIANJIN HAOYU TIANJIE ENERGY SAVING TECH

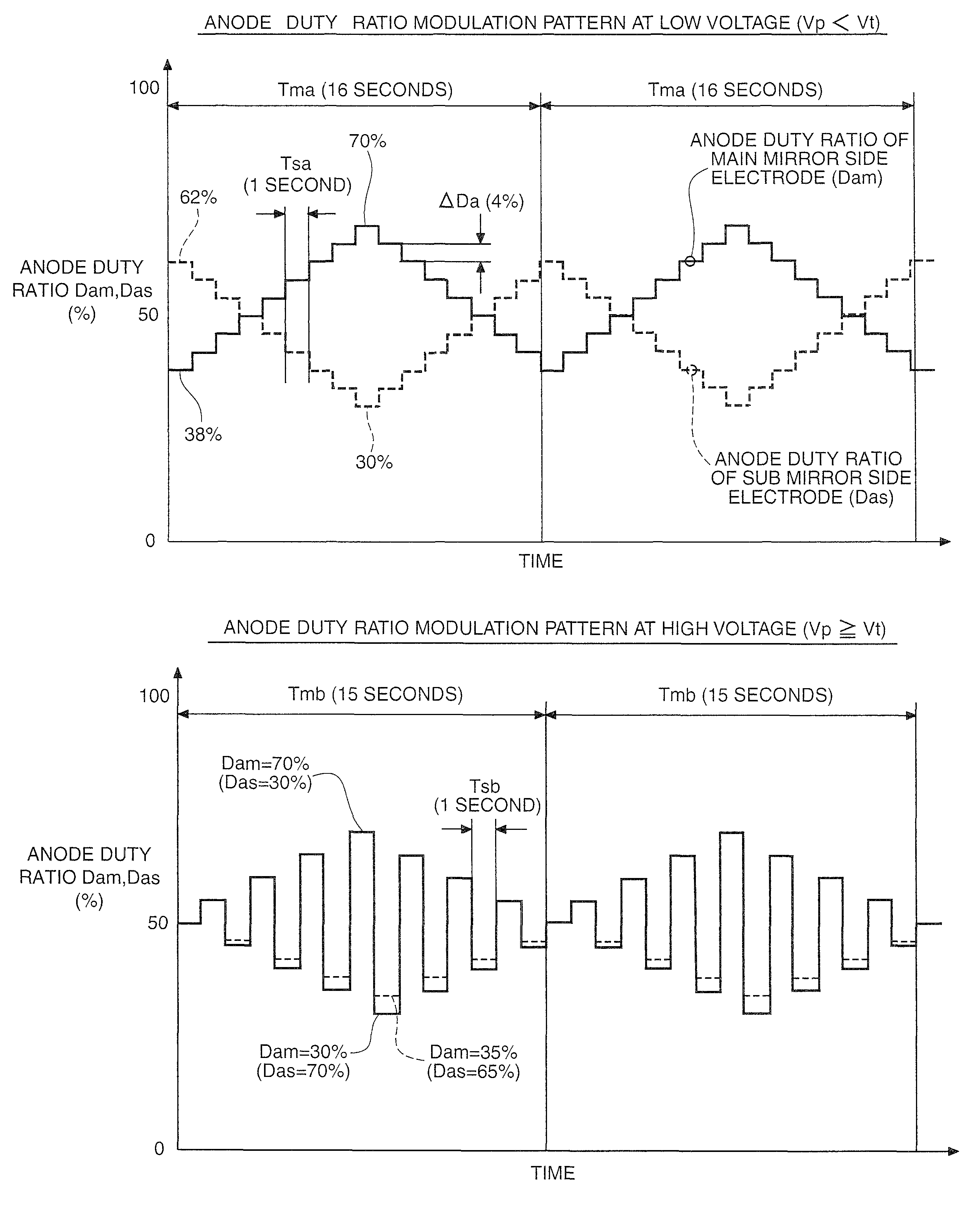

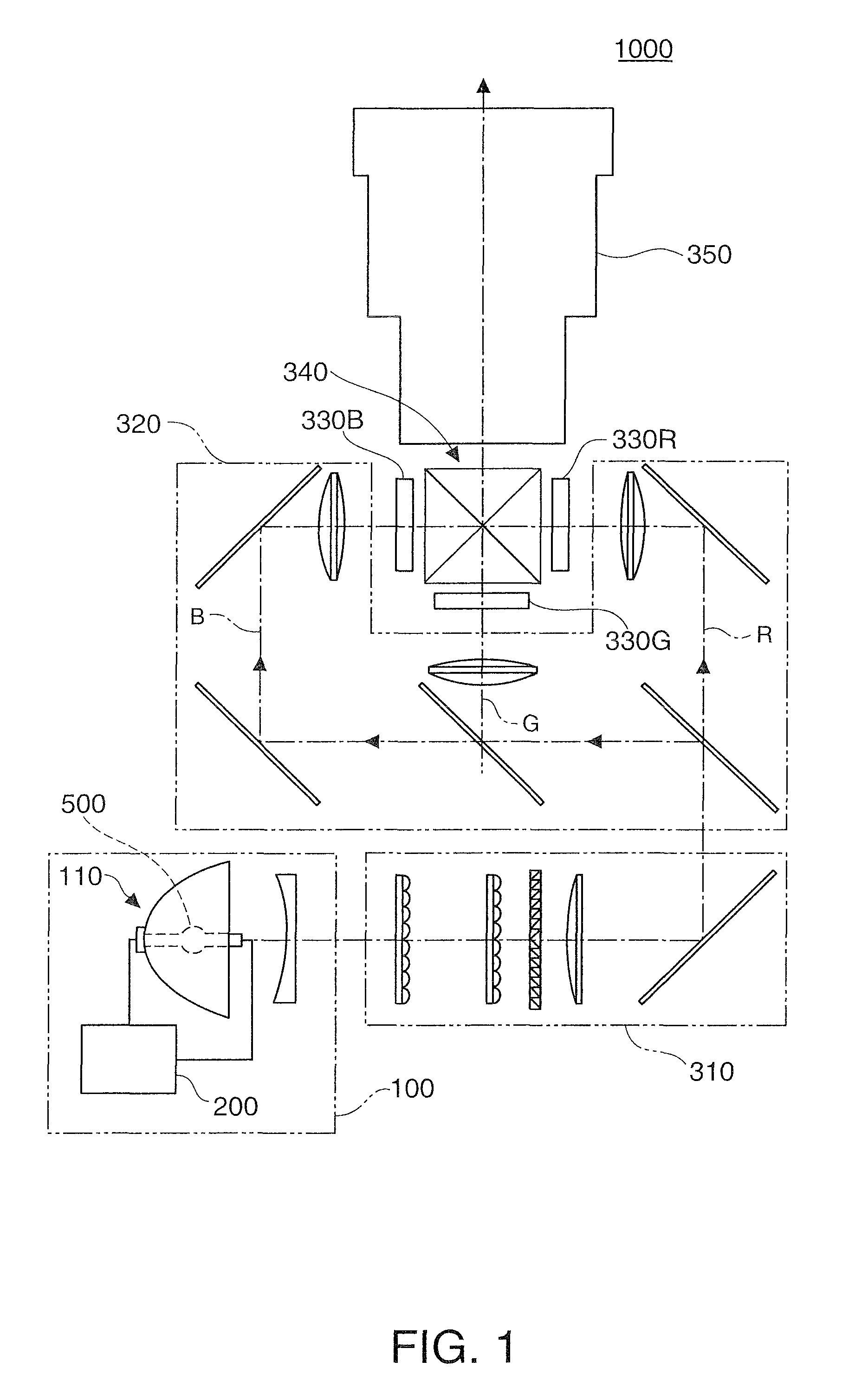

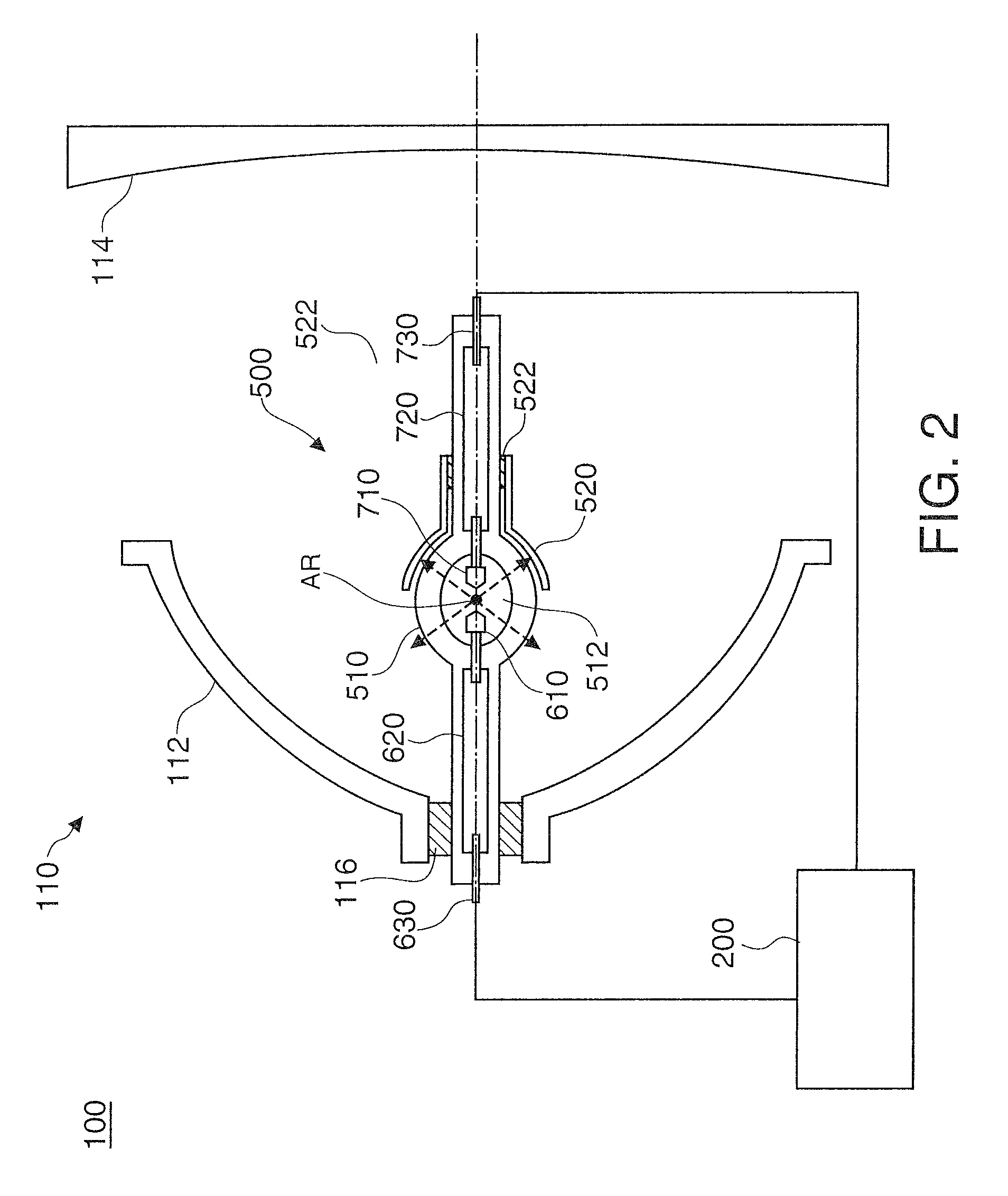

Driving device and driving method of electric discharge lamp, light source device, and image display apparatus

ActiveUS8129927B2Guaranteed usage periodElectrical apparatusElectric light circuit arrangementRetention periodElectric discharge

Owner:SEIKO EPSON CORP

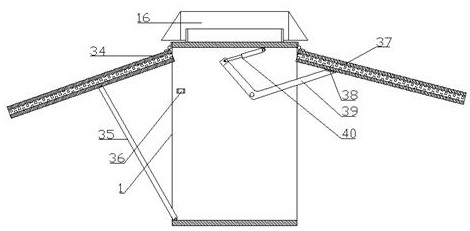

Outdoor prefabricated substation

PendingCN112467571AImprove the airTo facilitate external circulationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSnowpackStructural engineering

The invention discloses an outdoor prefabricated substation which comprises a frame, the frame is provided with an external support, a filter layer is arranged in the support, arc-shaped anti-collision beams are symmetrically arranged outside the support, anti-collision rods are connected between the anti-collision beams, the ends of the anti-collision beams are hinged to the rod ends of cylinderbodies, the cylinder bodies are fixedly connected to the frame, and baffles are arranged outside the anti-collision beams. Shielding plates are arranged at the upper parts and the lower parts of the baffles. A fan is arranged on the lower shielding plate in a penetrating mode through a cylinder frame, a folding plate is arranged between the anti-collision beams and the frame, preassembled supporting legs are arranged at the bottom of the frame, positioning bases are arranged on the inner sides of the supporting legs, four snow accumulation preventing roofs inclining downwards are arranged at the top of the frame, and a door plate and a back plate are movably arranged on the front side and the rear side of the frame respectively. Elements are convenient to install and overhaul through the back plate and the door plate, the anti-collision beams avoid frame deformation damage caused by external force collision, a filter layer reduces dust and water content of entering air, the fan ensuresair in the frame box body to be communicated with the outside, internal temperature is reduced, the supporting legs are used for pre-installation, and a positioning seat is convenient to position, install and fix.

Owner:马鞍山佳夫尼电气科技有限公司

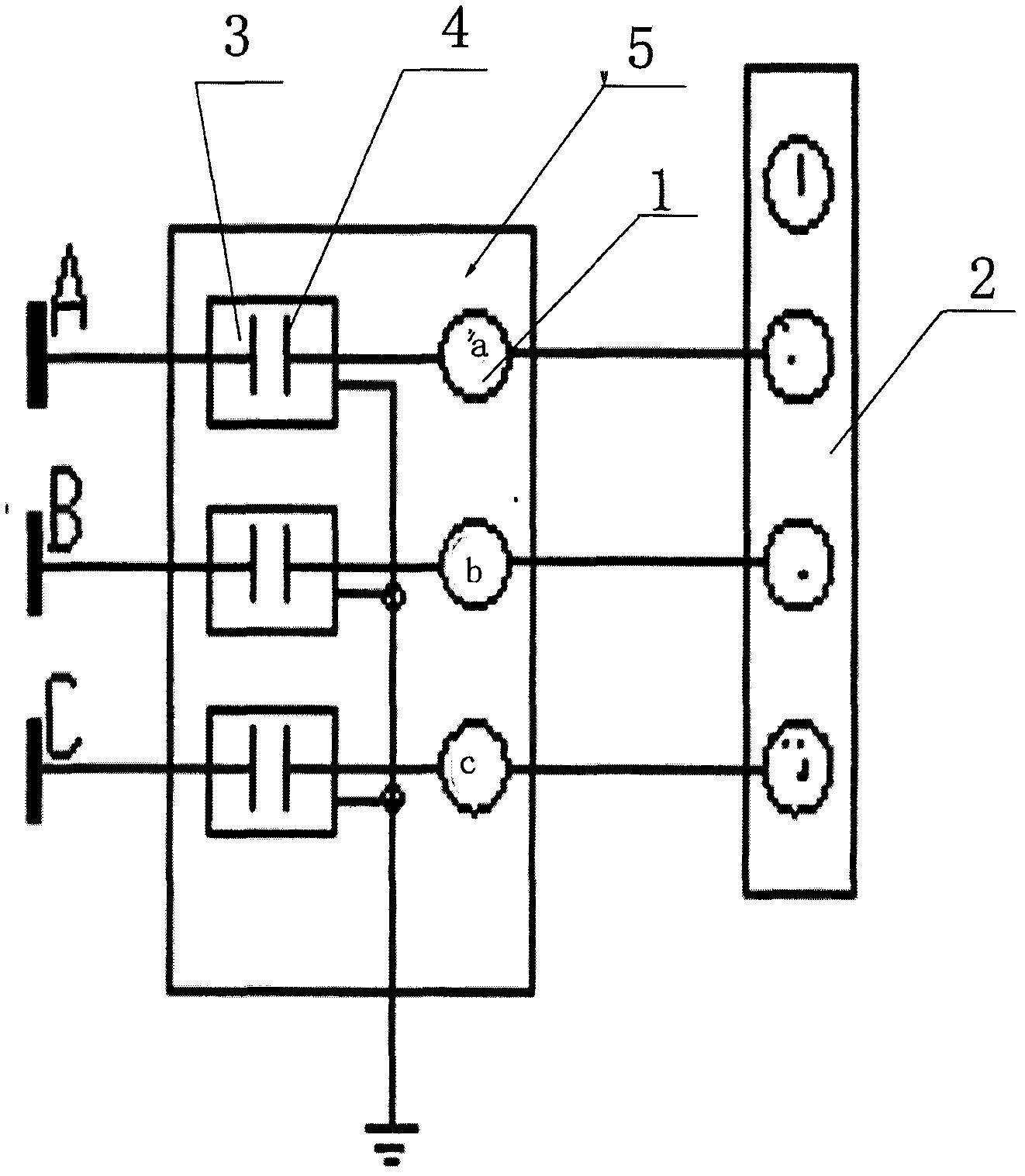

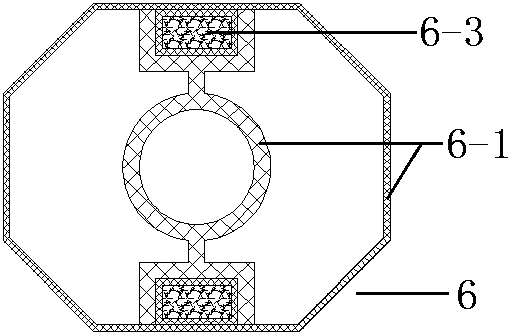

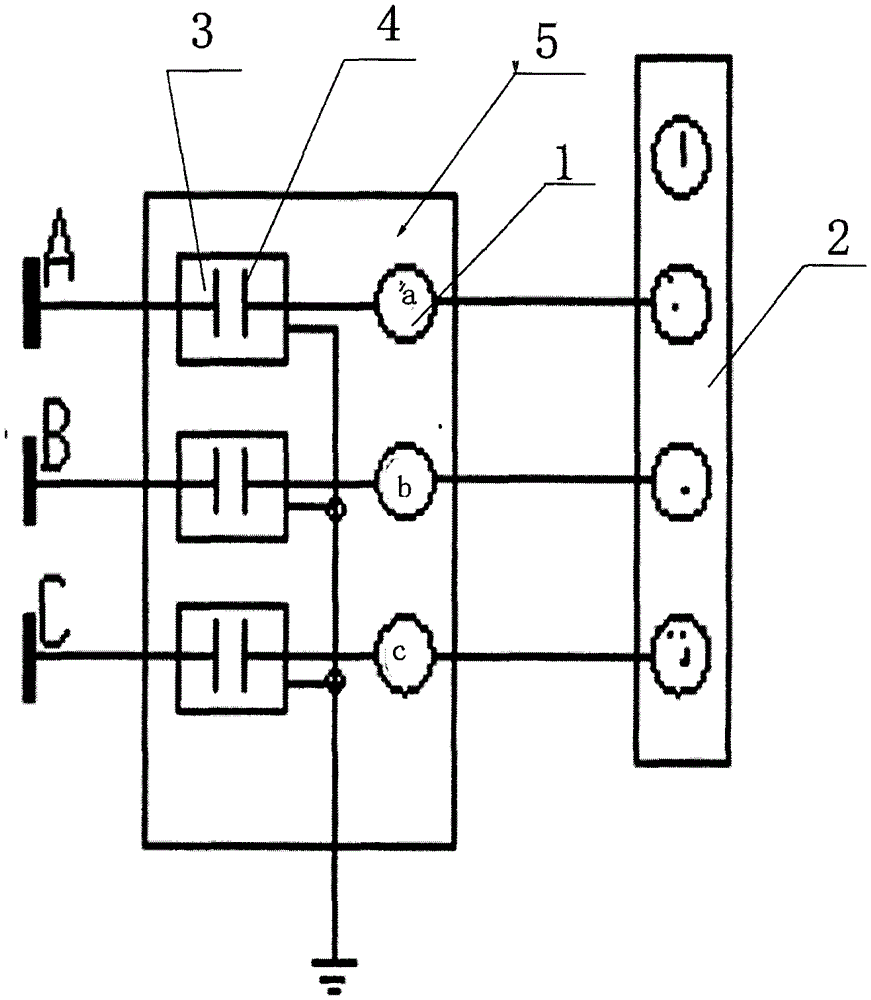

Locking device of grounding knife switch of switch cabinet

InactiveCN102931004AAvoiding accidents of electrified and grounded knife switchGuaranteed usage periodElectric switchesEngineeringThree-phase

The invention discloses a locking device of a grounding knife switch of a switch cabinet. The locking device of the grounding knife switch of the switch cabinet comprises a locking device body (5), wherein the locking device body (5) is provided with a three-phase electromagnetic generating device (1); one side of the three-phase electromagnetic generating device (1) is connected with a power supply (2), and the other end of the three-phase electromagnetic generating device (1) is linked with a grounding knife switch (3); the three-phase electromagnetic generating device (1) is linked with a baffle plate (4) of an operating hole in the grounding knife switch (3); a connecting rod (5) of the three-phase electromagnetic generating device (1) drives the baffle plate (4) to perform moving limit; when an electric cable is electrified, the three-phase electromagnetic generating device (1) drives the baffle plate (4) to move to close the operating hole in the grounding knife switch (3), and the grounding knife switch (3) stops operating; and when the electric cable is not electrified, the three-phase electromagnetic generating device (1) drives the baffle plate (4) to move to close the operating hole in the grounding knife switch (3), and the grounding knife switch (3) begins to operate.

Owner:STATE GRID CORP OF CHINA +3

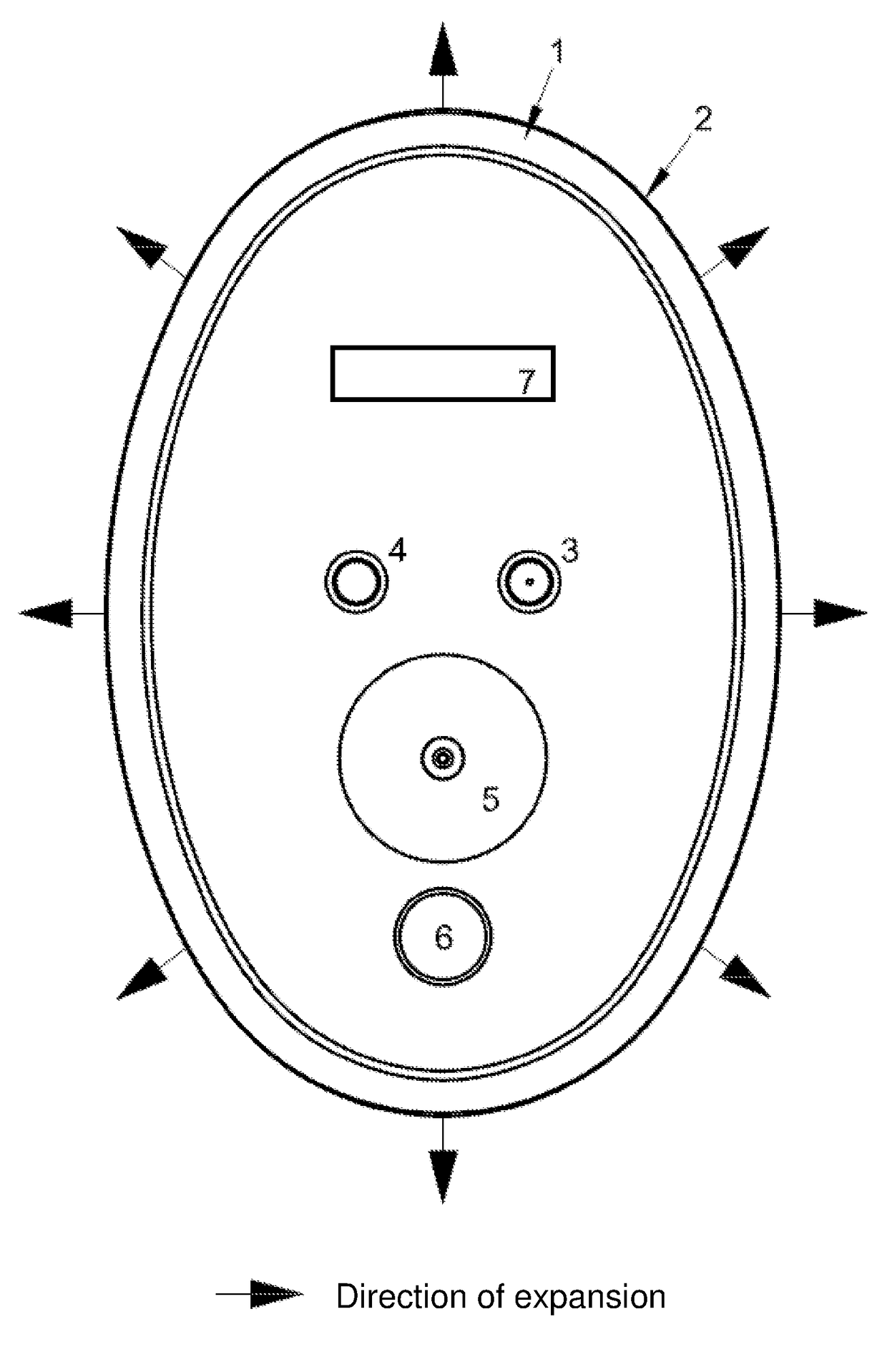

Test disc, test system and method for testing the seal of a glove which is installed in a port of an isolator, a glove and an isolator for use with the test system

ActiveUS20170234760A1Simple processImprove securityMeasurement of fluid loss/gain rateShielded cellsHermetic sealEngineering

A test system and a corresponding method for testing the seal of a glove which is installed in a port of an isolator, including a test disc which can be connected in a hermetically sealed fashion to the port. The glove and test disc define a sealed glove volume which can be placed under excess pressure. The test disc has a pressure-measuring device with a microprocessor and a memory for recording and storing a pressure profile in the glove volume and a data interface. The glove and port have identification elements which are read by a reading device of the test disc and information concerning the pressure profile along with the identities of the glove and port are transmitted wirelessly to an evaluation unit which estimates and records a residual period of use of the glove. A plurality of gloves in ports can be tested simultaneously.

Owner:KEIL MICHAEL

A badminton racket handle and its manufacturing method

The invention relates to a battledore handle and a manufacturing method thereof, belongs to the athletic sports appliance industry, and in particular relates to a battledore handle of a novel structure and a manufacturing method of the battledore handle. The battledore handle comprises a front cone and a carbon fiber handle, wherein a center hole is formed in the middle of the front cone; and grooves are designed in the upper and lower surfaces of the front cone. The manufacturing method comprises the following steps: filling cut PU foam materials in the two sides and grooves of the front cone, coating carbon fiber composite material prepreg cloth coated with resins on the exterior, inserting a front cone positioning pin into the center hole of the front cone so as to complete front cone preforming; and coiling the carbon fiber handle by using the cut carbon fiber prepreg cloth, and coating the front cone and the carbon fiber handle layer by layer by using the carbon fiber prepreg cloth, so that the front cone and the carbon fiber handle are tightly connected together, and an integrated battledore handle is formed. According to the application of the manufactured battledore handle disclosed by the invention on the battledore, the shock absorption performance of the front cone part of the battledore handle is increased, the strength of the battledore handle is stable, the precision is high, the stability of the battledore frame is effectively improved after ball hitting, the shock reduction performance of the battledore is improved, and sports injuries are reduced.

Owner:SUQIAN ADK COMPOSITES

Storage device for a small thermos bottle used in a kitchen

ActiveCN109124415ARealize storageAvoid being hitThermally-insulated vesselsLocking mechanismEngineering

A storage device for a small thermos bottle used in a kitchen includes a first square basket, one end of the first square basket is fixedly provided with a second square basket. The first square basket and the second square basket are connected through a fastening device. The fastening device comprises a semicircular lock body arranged on a top surface of first square basket, the top surface of the second square basket is provided with a semicircular fastener body which is coincident with the shape of the semicircular fastener body, the semicircular lock body is provided with a connecting piece slidably embedded into the semicircular buckle body, the connector is connected in the semicircular lock body through a connecting spring. A follow rod communicating with that outside through the circumferential wall of the semicircular lock body is fixed on the connector, the circumferential wall of the semicircular lock body is provided with an arc-shaped track groove through which the followrod slides, and a driving locking mechanism for driving the connector sliding into the semicircular buckle body is arranged on the second square basket. The storage device can store a plurality of thermos bottles, and can be arranged in a flat and folded state according to the shape of the kitchen space.

Owner:SHAOXING KEQIAO XINFEI TECH CO LTD

Test disc, test system and method for testing the seal of a glove which is installed in a port of an isolator, a glove and an isolator for use with the test system

InactiveUS20150192492A1Simple processImprove securityDetection of fluid at leakage pointMeasurement of fluid loss/gain rateHermetic sealEngineering

A test system and a corresponding method for testing the seal of a glove which is installed in a port of an isolator, including a test disc which can be connected in a hermetically sealed fashion to the port. The glove and test disc define a sealed glove volume which can be placed under excess pressure. The test disc has a pressure-measuring device with a microprocessor and a memory for recording and storing a pressure profile in the glove volume and a data interface. The glove and port have identification elements which are read by a reading device of the test disc and information concerning the pressure profile along with the identities of the glove and port are transmitted wirelessly to an evaluation unit which estimates and records a residual period of use of the glove. A plurality of gloves in ports can be tested simultaneously.

Owner:KEIL MICHAEL

A switch cabinet grounding knife switch locking device

The invention discloses a locking device of a grounding knife switch of a switch cabinet. The locking device of the grounding knife switch of the switch cabinet comprises a locking device body (5), wherein the locking device body (5) is provided with a three-phase electromagnetic generating device (1); one side of the three-phase electromagnetic generating device (1) is connected with a power supply (2), and the other end of the three-phase electromagnetic generating device (1) is linked with a grounding knife switch (3); the three-phase electromagnetic generating device (1) is linked with a baffle plate (4) of an operating hole in the grounding knife switch (3); a connecting rod (5) of the three-phase electromagnetic generating device (1) drives the baffle plate (4) to perform moving limit; when an electric cable is electrified, the three-phase electromagnetic generating device (1) drives the baffle plate (4) to move to close the operating hole in the grounding knife switch (3), and the grounding knife switch (3) stops operating; and when the electric cable is not electrified, the three-phase electromagnetic generating device (1) drives the baffle plate (4) to move to close the operating hole in the grounding knife switch (3), and the grounding knife switch (3) begins to operate.

Owner:STATE GRID CORP OF CHINA +3

Mouse pen and photoelectric control switch thereof

InactiveUS8847889B2Guaranteed usage periodReduce overall outer diameterCathode-ray tube indicatorsInput/output processes for data processingJoystickEngineering

A mouse pen and a photoelectric control switch thereof are provided, the photoelectric control switch includes a control rod in a shell moving between on-position and off-position, an optical coupling sensor comprising a light emitter and light receiver disposed on an extension line of the control rod, and an elastic element for resetting the control rod. The control rod includes a first end near the optical coupling sensor and equipped with a reflection element, and a second end for driving the control rod towards the optical coupling sensor which protrudes an orifice of the shell; at the on-position, light emitting from the light emitter is received by the light receiver after being reflected by the reflection element, while at the off-position, light cannot be received. The photoelectric control switch implements non-contact on / off controlling with the optical coupling sensor and the control rod, responses sensitively, and has longer lifetime.

Owner:SHENZHEN YIBAO TECH

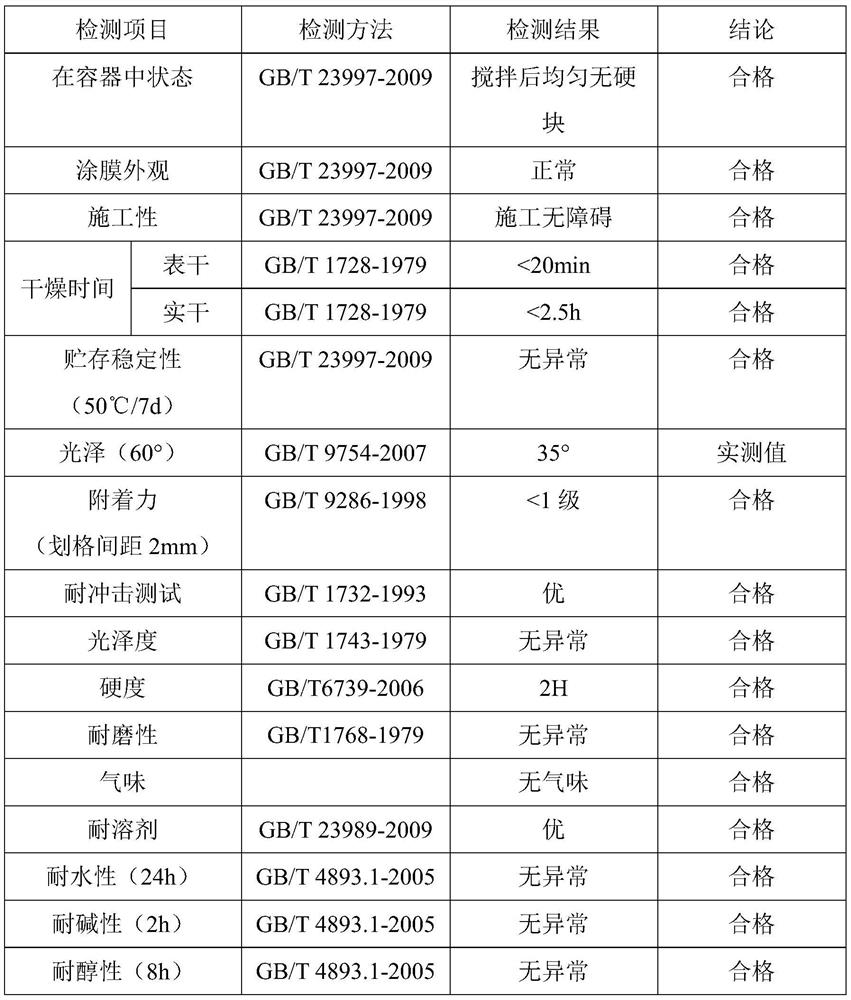

Thin, transparent and flash anti-shrinkage top-coat as well as preparation method and use method of thin, transparent and flash anti-shrinkage top-coat

PendingCN114806363AImprove textureImprove perceptionPolyurea/polyurethane coatingsSolid woodDefoaming Agents

The invention belongs to the technical field of C09D coatings, and particularly relates to a thin, transparent and flash anti-shrinkage top-coat as well as a preparation method and a use method thereof. The invention relates to a thin, transparent and flash anti-shrinkage top-coat, which is prepared from the following raw materials: a component A and a component B, the weight ratio of the component A to the component B is 1: (0.1-0.5); in the preparation process of the thin, transparent and flash anti-shrinkage varnish prepared by the invention, through the mutual synergistic effect of the dispersing agent, the defoaming agent, the flatting agent and the hand feeling additive, the problem of bubbles possibly occurring in the preparation process can be solved, and the problems of construction difficulty and possible pinhole phenomenon on the surface of solid wood in the construction process are solved; the thin, transparent and flash-proof shrinkage varnish provided by the invention has excellent stability, especially has excellent transparency and gloss retention in the long-time placement and use process, and is suitable for industrial production.

Owner:上海君子兰新材料股份有限公司

Chassis device for electric wheelchair

A chassis device of an electric wheelchair includes a frame unit, a linking unit, a wheel unit and a power unit. The frame unit is provided with a first arrangement of a bottom border which is provided with a first pin joint point, a second arrangement of a standing post which is provided with a second pin joint point and the second arrangement of the standing post of a third pin joint point. Thelinking unit is provided with two connecting rod groups, which are respectively arranged at two sides of the frame unit. The first connecting rod group is provided with an upper rocker which is articulated at the third pin joint point and extends forwards and backwards, a lower rocker which is articulated at the second pin joint point and extends forwards, a bottom rod which is articulated at thefirst pin joint point and extends backwards and a back rod which is articulated with the upper rocker and the bottom rod. The bottom rod and the back rod are used to absorb the oblique angle of the rod, which is caused by the up and down swing to bring comfort to the sitting person.

Owner:KYMCO

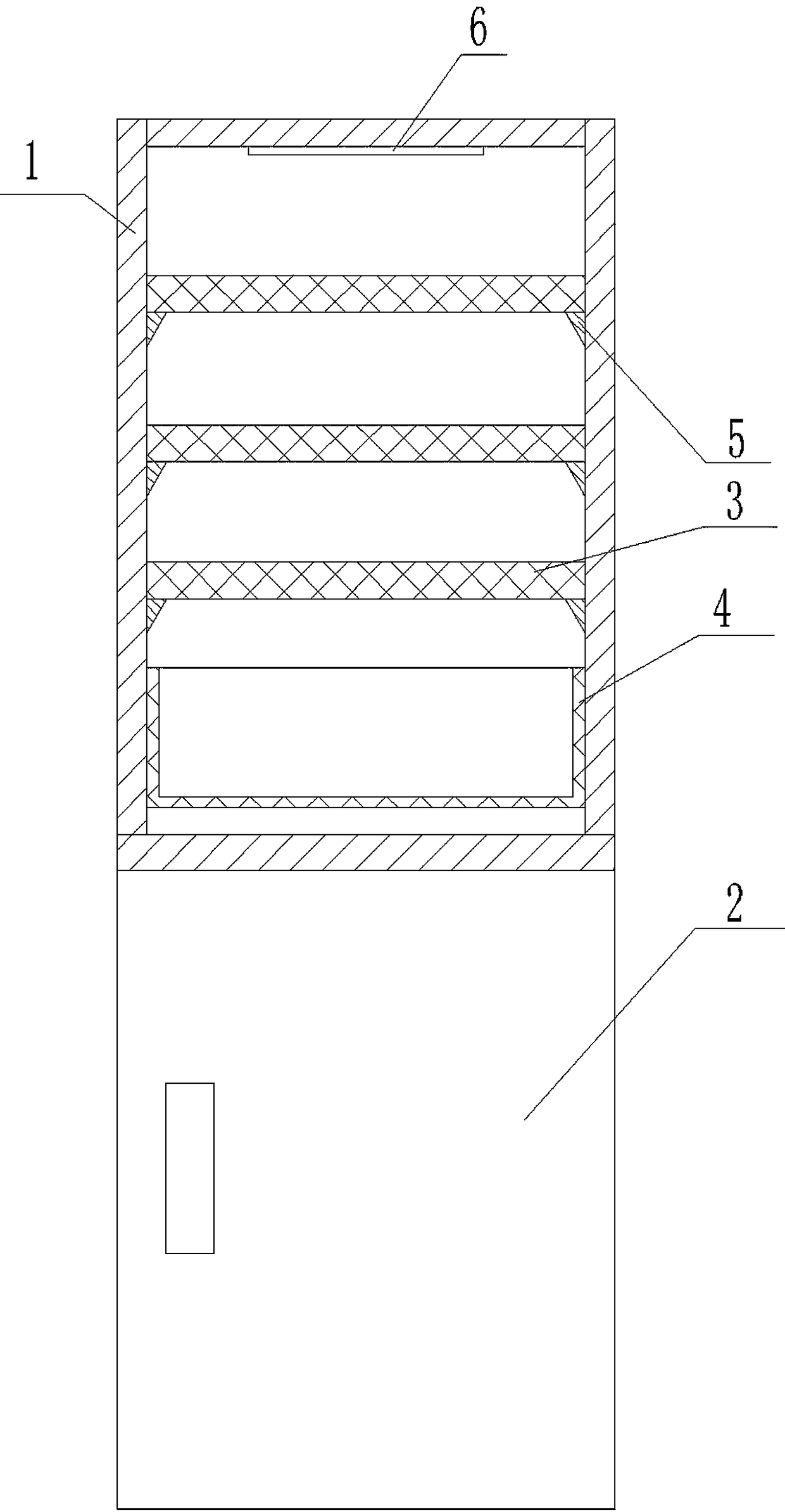

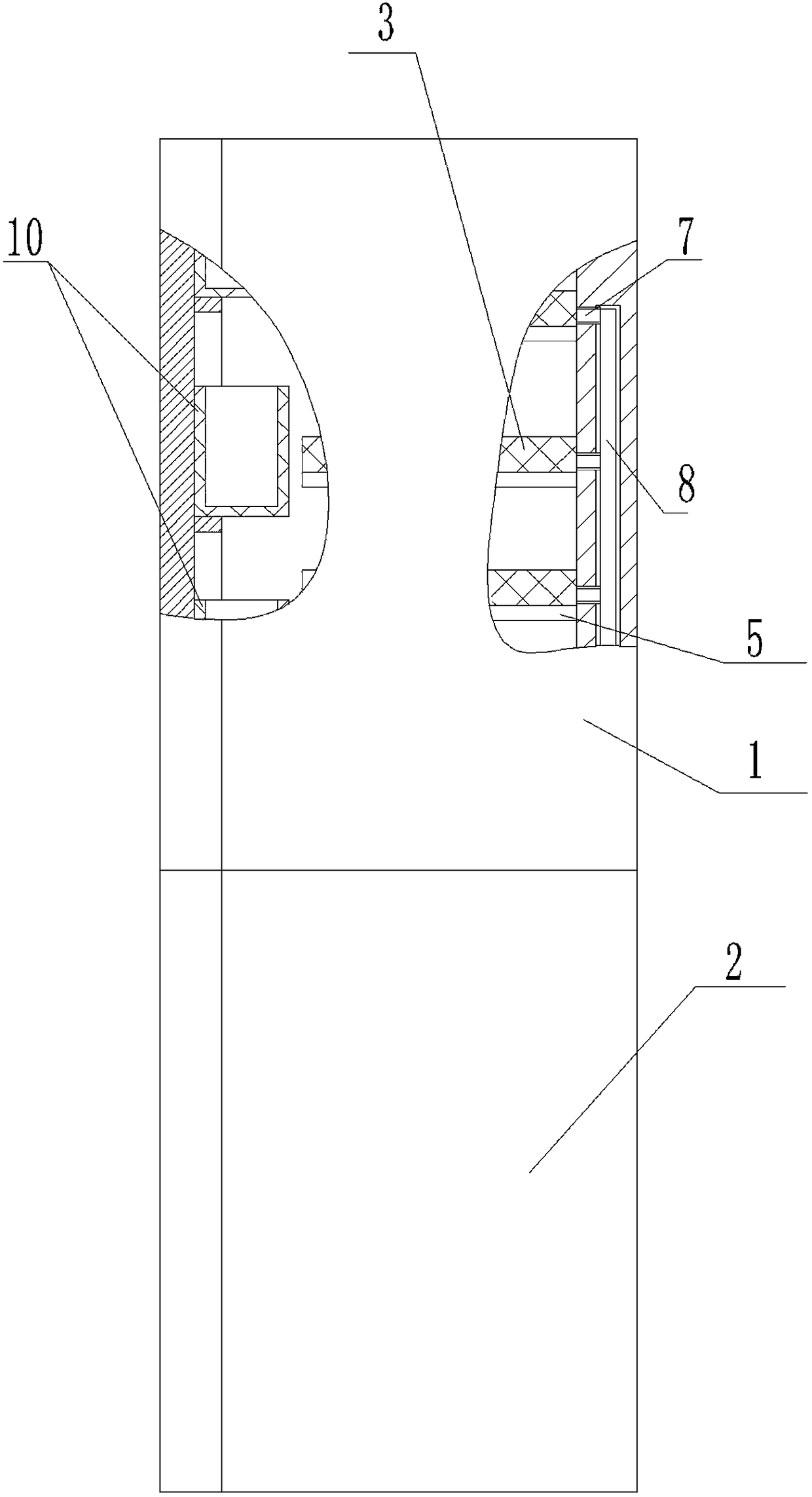

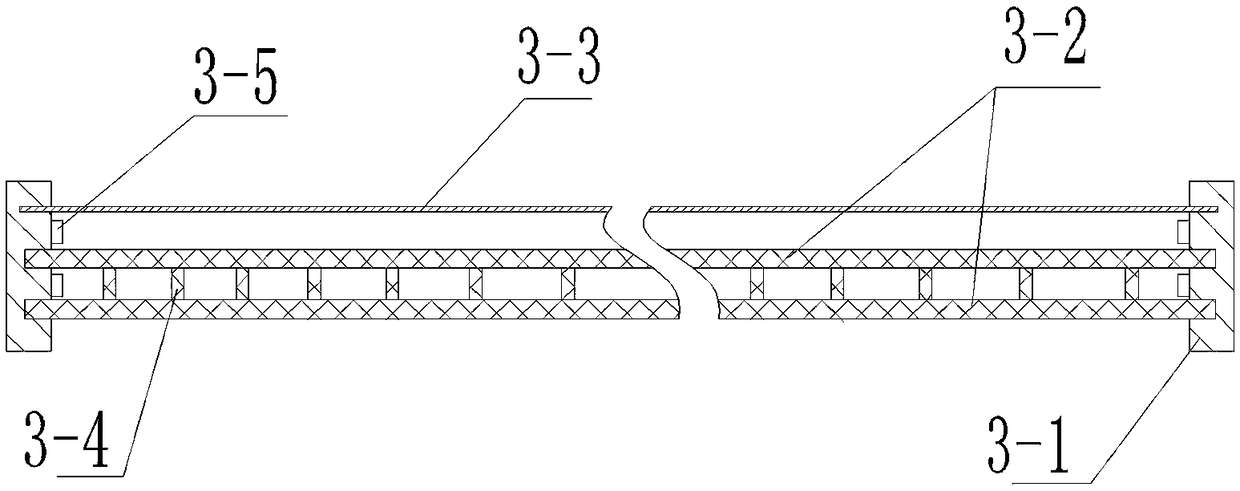

Refrigerator with antibacterial and deodorizing refrigeration chamber

InactiveCN108518911ALarge specific surface areaHigh bonding strengthLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention discloses a refrigerator with an antibacterial and deodorizing refrigeration chamber and belongs to the second-generation photocatalyst antibacterial technical field. The refrigerator comprises the refrigeration chamber, a freezing chamber, a matched refrigeration system and a matched control circuit, and a partition carrier plate device is arranged in the refrigeration chamber in amatched mode. The refrigerator comprises a sizing framework and a photocatalyst film positioned in the sizing framework and compounded on the surface of tempered glass by virtue of a sintering process. According to the refrigerator, the preservation time is prolonged, growth of bacteria can be restrained, the air purification concept of the refrigeration chamber of the refrigerator is improved, breezing, multiplying and peculiar smell of bacteria and viruses are restrained, and the new conception of low-temperature preservation is realized.

Owner:伦慧东 +1

PVC formula

InactiveCN113817281AReduce plasticizing temperatureImprove plastic processing performancePolymer sciencePropanoic acid

The invention relates to a PVC (polyvinyl chloride) formula which is prepared from the following raw materials in parts by weight: 50-70 parts of high-polymerization-degree PVC resin, 30-50 parts of low-polymerization-degree PVC resin, 100 parts of high-polymerization-degree resin and low-polymerization-degree resin, 30-40 parts of a dioctyl phthalate (DOP) plasticizer, 1-3 parts of an organic tin heat stabilizer, 0.5-1.5 parts of a G70S lubricant, 1-2 parts of tetrakis [beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 1-2 parts of 2-hydroxy-4-N-octyloxybenzophenone, 0.1 part of octadecanamide, and 1-3 parts of a processing aid. The invention has the beneficial effects that the plasticizing temperature during PVC processing is reduced, the melt viscosity is reduced, the plasticizing processing performance of the material is improved, and the surface quality of the product is improved. moreover, the aging resistance and oxidation resistance of the PVC product are improved, the failure process of the PVC product is slowed down, the service life of the product is guaranteed, and the PVC product is low in cost and suitable for popularization and application.

Owner:渤海英科(河北)科技有限公司

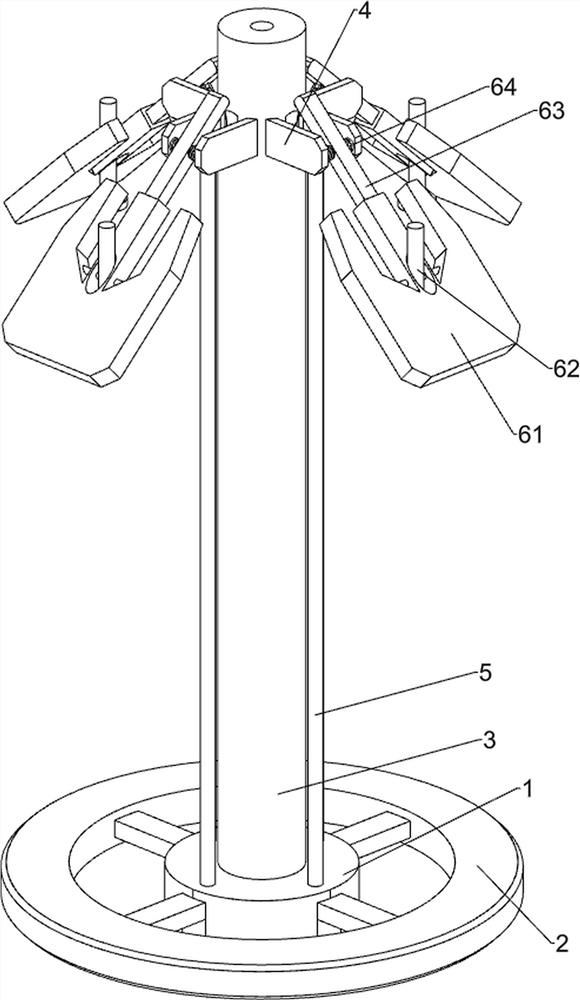

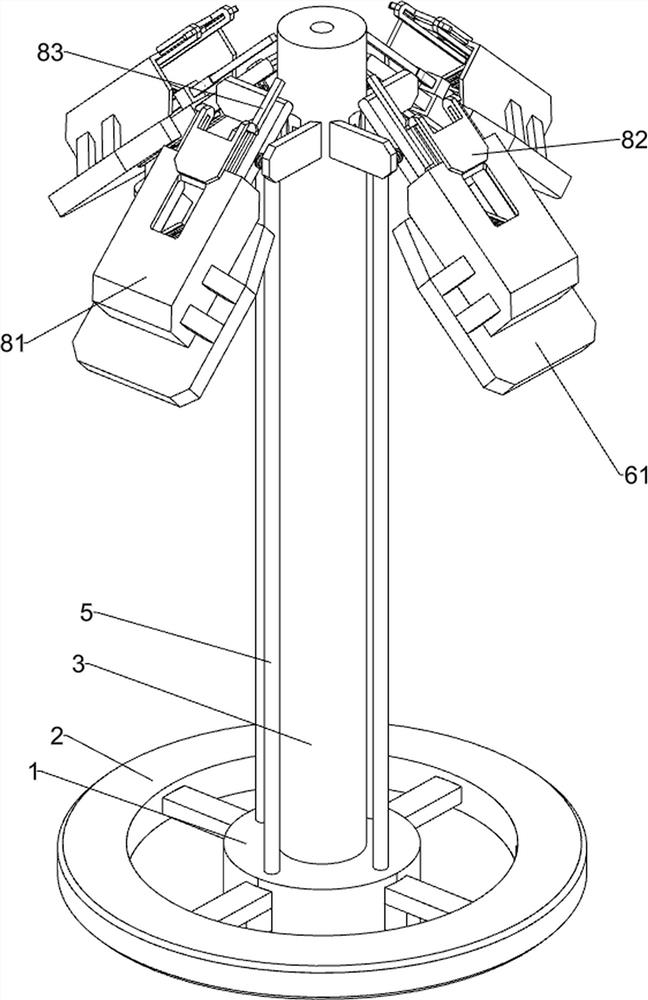

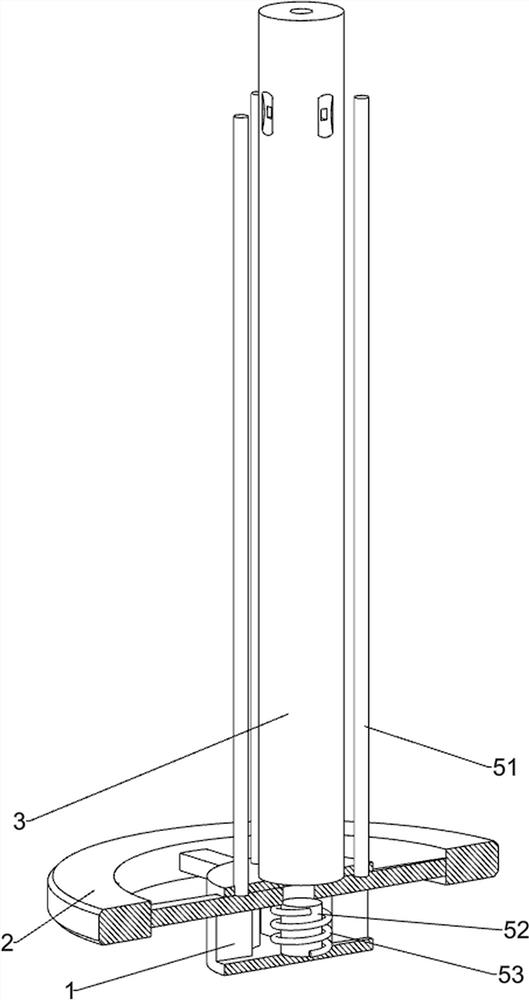

LED lamp supporting equipment for improving visibility in foggy days

InactiveCN113944910AImprove visibilityImplement basic functionsMechanical apparatusLighting elementsEngineeringRoad surface

The invention relates to supporting equipment, in particular to LED lamp supporting equipment for improving visibility in foggy days. Mainly provides the LED lamp supporting equipment for improving the visibility in foggy days, which can reduce the probability that haze is attached to LED lamps, increase the number of the LED lamps and improve the visibility. The LED lamp supporting equipment for improving visibility in foggy days comprises a base, a pressing block, a supporting column, first connecting plates, a supporting mechanism and a lighting mechanism, the pressing block is slidably arranged on the outer side of the base, the supporting column is arranged at the top of the base, the supporting mechanism is connected between the top of the pressing block and the base, and the four pairs of first connecting plates are arranged on the outer side of the upper portion of the supporting column at equal intervals; and the lighting mechanism capable of being provided with LED lamps is connected between the first connecting plates; and the LED lamps can be installed in connecting grooves, a placement plate is opened and does not shield the LED lamps any more, in this way, the LED lamps can be turned on to irradiate the road surface in the foggy days, the visibility is improved, and the basic function is achieved.

Owner:深圳市金宝贝科技有限公司

Flexible solar battery component and packaging method thereof

ActiveCN102856403BSufficient weather resistanceSufficient tensile failure strengthFinal product manufacturePhotovoltaic energy generationSolar batteryBattery cell

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com